Autotrol

®

Performa Valve with 400 Series Control water Conditioning Control System

•

5

400 SErIES CoNtrol SEttINgS

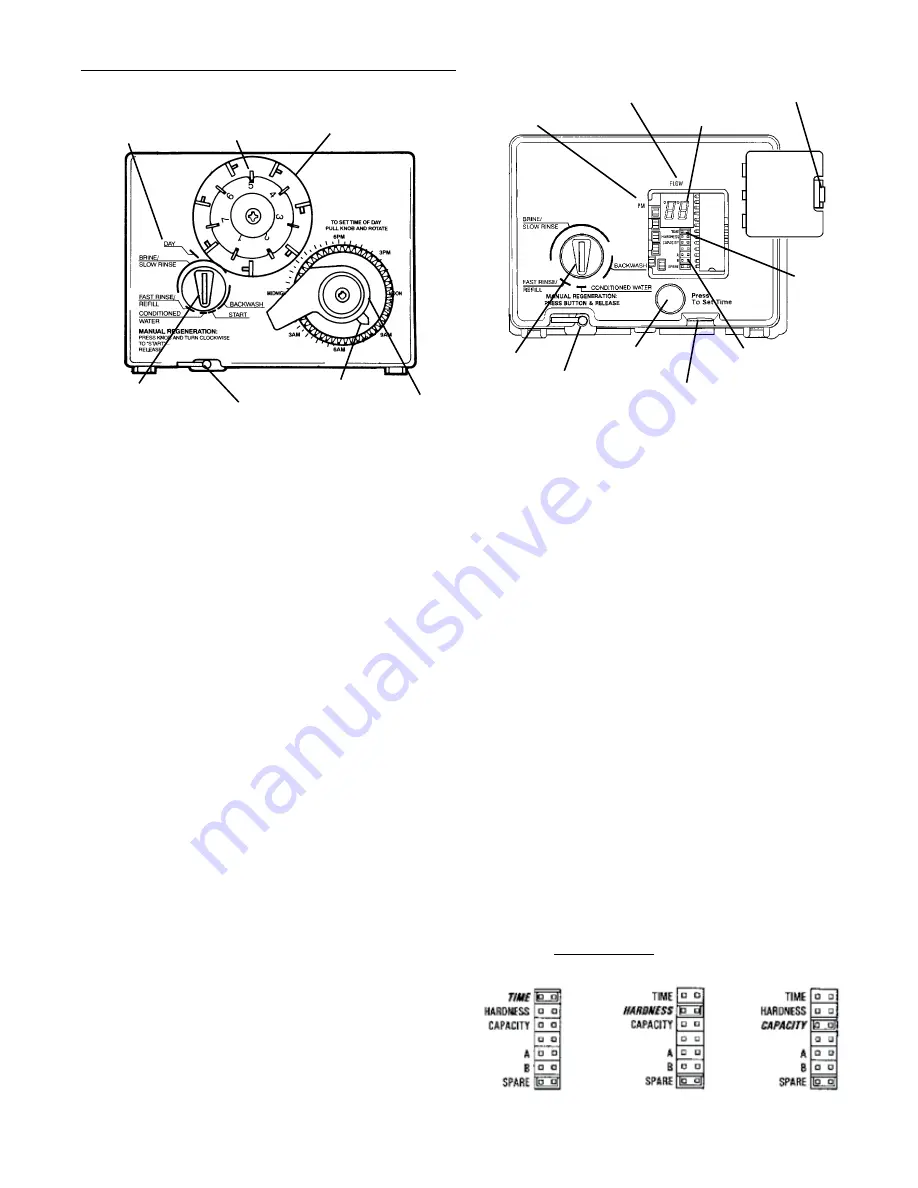

440i Control (obsolete)

Day Arrow

Skipper Pins

Skipper Wheel

Indicator Knob

Timer Locking Pin

Time Arrow

Timer Knob

Figure 5

Programming

1. Set days of regeneration on skipper wheel (Figure 5).

•

Pull all skipper pins outward (away from control).

•

Rotate skipper wheel until day arrow points to current

day or number 1.

•

Depress skipper pin(s) at day(s) for which regeneration

is desired.

2. Set the time of day.

•

Grasp timer knob and pull outward.

•

Rotate in either direction until the timer arrow points to

the actual time of day.

•

Release timer knob.

NotE:

With the time of day properly set, the conditioner will

regenerate at about 2:30 a.m. If you prefer to have

the unit regenerate at an earlier or later time, simply

set current time-of-day accordingly (e.g., to have the

unit regenerate at 4:30 a.m.—two hours later—set

the clock two hours earlier than the actual time

of day).

NotE:

the timer locking Pin should always be horizontal

(Figure 5) during operation.

460i Control

PM Indicator

Hour Time Display

Access

Door

Indicator Knob

Timer Locking Pin

Raised Tab

Jumper

Water Flow Indicator

Spare

Jumper

Transformer

Plug Receptacle

Time Set Button

Figure 6

Programming

Plug the wall-mount transformer into a functioning electrical

outlet that is not controlled by a switch. Plug the transformer

into the transformer plug receptacle on the control.

Open the access door by pushing the raised tab on the door

toward the left while pulling the tab out (Figure 6).

time of Day Setting

With the jumper on the set of pins next to the word TIME

(Figure 7), set the time of day to the closest hour by pressing

the black TIME SET button. PM hours are indicated by a light

next to the letters PM on the display window.

NotE:

the use of a small needle-nose pliers will aid in

moving the jumper.

NotE:

the unit is factory set to regenerate at 2:00 a.m. If

you prefer to have the unit regenerate at an earlier

or later time, simply set the current time of day

accordingly (e.g., to have the unit regenerate at 4:00

a.m.—two hours later—set the clock two hours

earlier than the actual time of day).

NotE:

the timer locking Pin should always be horizontal

(Figure 6) during operation.

Hardness Setting

Move the jumper to the set of pins next to the word HARDNESS

(Figure 8). Press the black TIME SET button until the hardness

of the incoming water supply is displayed. The hardness range

is from 1 to 99 grains per gallon.

To change water hardness stated in parts per million (PPM) to

grains per gallon (GPG) use this formula:

Parts per Million = Grains per Gallon

17.1

Figure 7

Figure 8

Figure 9