OWNER’S MANUAL

Engine Drive Self Priming Pump

© 2014

F00630 (03/03/2014)

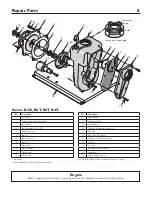

B2X, B3T, B4T, B4Z

Important

For best possible performance and continuous, satisfactory operation,

read these instructions before installing your new pump.

Should service be required, this manual can be a valuable guide.

It should be kept near the installation for ready reference.