Installer Manual Fleck 5812 - XTR - Installation

46 / 132

Ref. MKT-IM-019 / E - 14.10.2019

5.5.

Valve connection to piping

The connections should be using PTFE (plumber’s tape) on the threads if using the threaded

connection type.

In case of heat welding (metal type connection), the connections should not be made to the valve when

soldering.

Note

See chapter 3.3. Description and components location, page 19 to identify the connections.

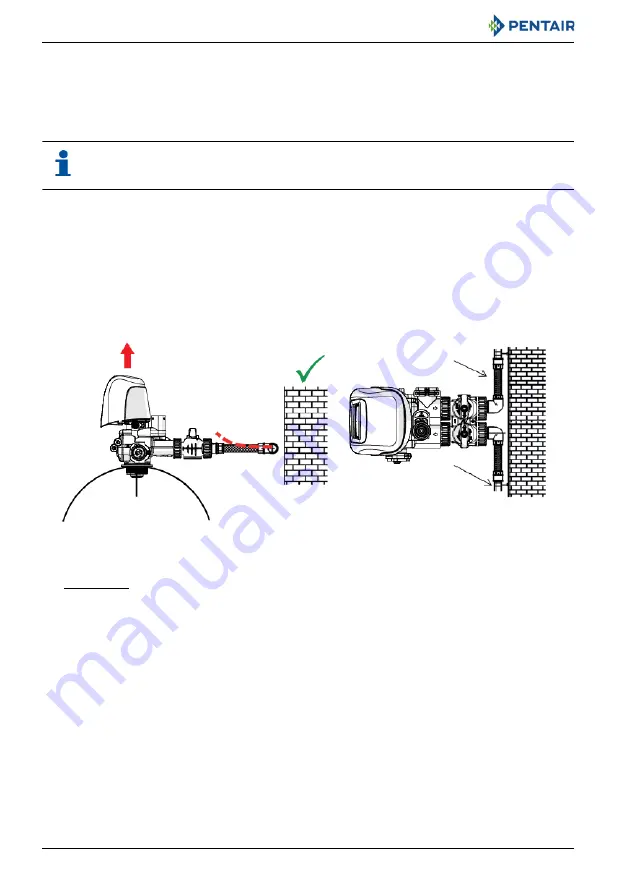

5.5.1. Top-mounted valve installation

When pressurized, any composite tank will expand both vertically and circumferential. In order to

compensate the vertical expansion, the piping connections to the valve must be flexible enough to

avoid overstress on the valve and tank.

In addition, the valve and tank should not be supporting any part of the piping weight. This is hence

compulsory to have the piping fixed to a rigid structure (e.g. frame, skid, wall…) so that the weight of

it is not applying any stress on the valve and tank.

•

The diagrams above illustrate how the flexible piping connection should be mounted;

•

in order to adequately compensate the tank elongation the flexible piping must be installed

horizontally

;

200 mm flexible

Support to the wall

Summary of Contents for FLECK 5812 XTR

Page 1: ...INSTALLER MANUAL WATER PURIFICATION FLECK 5812 XTR...

Page 18: ...Installer Manual Fleck 5812 XTR Description 18 132 Ref MKT IM 019 E 14 10 2019 3 2 2 Base 4...

Page 108: ...Installer Manual Fleck 5812 XTR Maintenance 108 132 Ref MKT IM 019 E 14 10 2019...

Page 110: ...Installer Manual Fleck 5812 XTR Maintenance 110 132 Ref MKT IM 019 E 14 10 2019...

Page 132: ...www pentairaquaeurope com...