Fleck 6700XTR Downflow

Service Manual

42132 Rev E JL10

TABLE OF CONTENTS

JOB SPECIFICATION SHEET ...............................................1

INSTALLATION ......................................................................2

TIMER OPERATION ..............................................................2

MASTER PROGRAMMING MODE FLOW CHART ...............4

MASTER PROGRAMMING MODE ........................................6

USER PROGRAMMING MODE & FLOW CHART .................8

DIAGNOSTIC PROGRAMMING MODE FLOW CHART ........9

DIAGNOSTIC PROGRAMMING MODE ...............................10

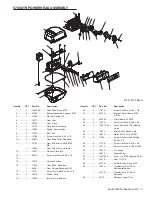

6700XTR POWERHEAD ASSEMBLY ....................................11

CONTROL VALVE ASSEMBLY ..............................................12

METER ASSEMBLY ...............................................................13

BYPASS VALVE ASSEMBLY,

NON-METALLIC .....................................................................14

BYPASS VALVE ASSEMBLY, BRASS ....................................15

2300 SAFETY BRINE VALVE.................................................16

2310 SAFETY BRINE VALVE.................................................17

TROUBLESHOOTING - TIMER .............................................18

TROUBLESHOOTING - CONTROL VALVE ...........................19

GENERAL SERVICE HINTS FOR METER CONTROL .........20

WATER CONDITIONER FLOW DIAGRAMS .........................21

VALVE WIRING DIAGRAM ....................................................22

SERVICE ASSEMBLIES ........................................................23

JOB SPECIFICATION SHEET

NOTE: Some options may not be available depending on valve model or

other options chosen.

Circle and/or fill in the appropriate data for future reference.

1. System Type:

A. Meter Immediate

B. Time Clock Delayed

C. Volume Override Delayed

D. Volume Override Immediate

E. Meter Delayed Weekly Reserve

F. Meter Delayed Variable Reserve

G. Meter Delayed Fixed Reserve

2. Valve Type:

A. 56XT/6700

B. Proprietary C

3. Regenerant Flow:

A. Downflow

B. Upflow

C. Downflow Double Backwash

D. Upflow Backwash

E. Filter

F. Upflow Variable Flow

4. Display Format:

A. U.S.

B. Metric (French Degrees, German Degrees, or PPM)

5. Unit Capacity: ���������

Grains/French Degrees/German Degrees/PPM

6. Water Hardness: �������

Grains/French Degrees/German Degrees/PPM

7. Capacity Safety Factor:

Zero or______________________________%

8. Volume Override: ����������������������������

(Gallons or M

3

)

9. Regeneration Day Override:

A. Off

B. Every ______________________________________________ Days

10. Regeneration Time:

A. Delayed __________________________________________ AM/PM

B. Metered Immediate

11. Regeneration Cycle:

A. Step #1 _ _ : _ _ : _ _

B. Step #2 _ _ : _ _ : _ _

C. Step #3 _ _ : _ _ : _ _

D. Step #4 _ _ : _ _ : _ _

E. Step #5 _ _ : _ _ : _ _

12. Media Volume: ����������������������������������

(CuFt or Liter)

13. Salt Dosage: ���������������������������

(lbs/CuFt or grams/Liter)

14. BLFC Size:

_____________________________________________ gpm

15. Auxiliary Relay:

A. Enabled

a. Auxiliary Relay Start 1 _ _ : _ _ : _ _

b. Auxiliary Relay End 1 _ _ : _ _ : _ _

c. Auxiliary Relay Start 2 _ _ : _ _ : _ _

d. Auxiliary Relay End 2 _ _ : _ _ : _ _

B. Disabled

16. Chemical Pump:

A. Enabled

B. Disabled

17. CPO Aux Relay Volume: �������������������������

(Gallons or M

3

)

18. CPO Aux Relay:

_ _ : _ _ : _ _

19. Flow Meter Size:

A. 0.75" Paddle

B. 0.75" Turbine

20. Generic Flow Meter for Maximum Flow Rate:

Add_____Gallons every _ _