6

HYD983 (06-08-20)

INSTALLATION

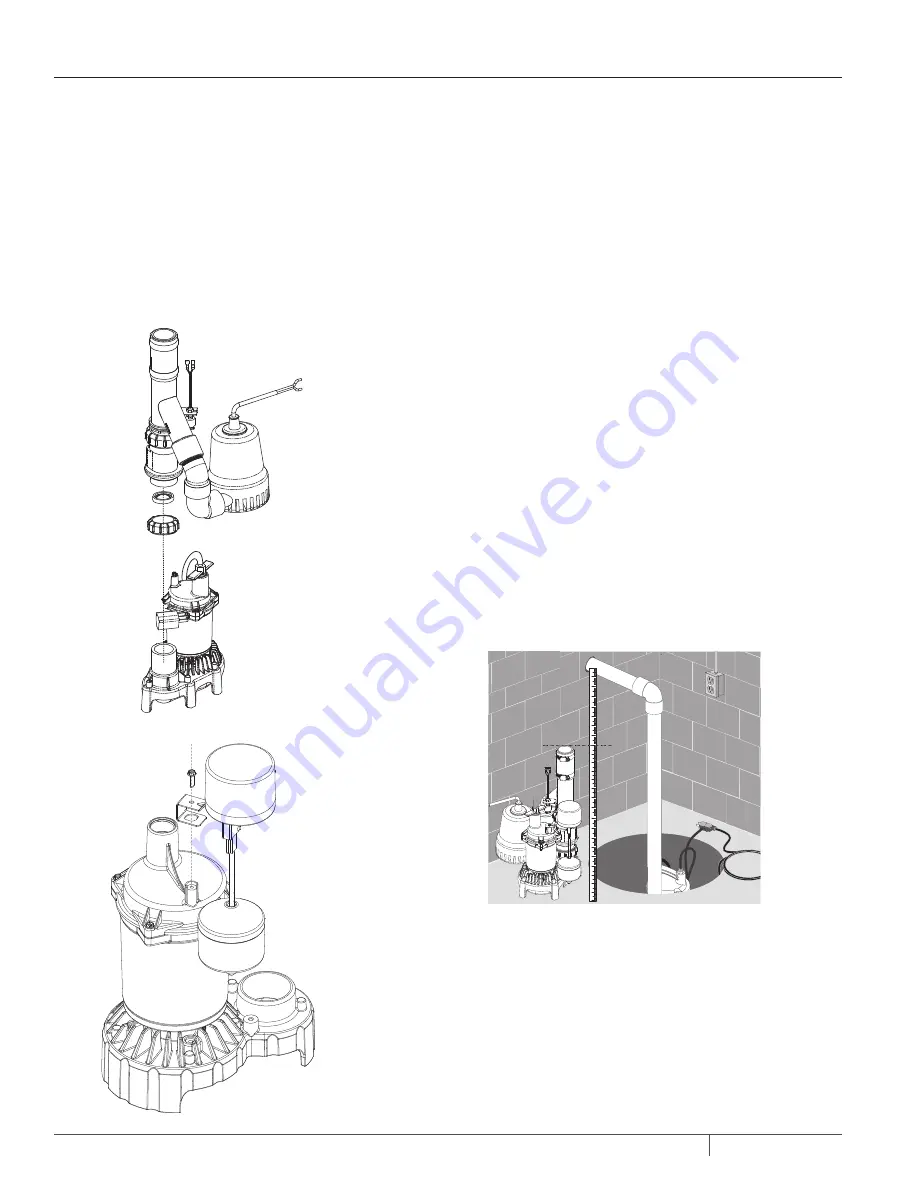

BACKUP ASSEMBLY INSTALLATION

Attach backup pump assembly to primary pump. To do so,

un-screw bottom nut on check valve and remove rubber seal.

Place nut from check valve around discharge PVC pipe on

primary pump, then place rubber seal. Attach backup pump

assembly to the primary pump by tightening nut to the rest

of the check valve unit. Adjust backup pump to sit at an angle

(approx. 10°).

FLOAT SWITCH INSTALLATION

Assemble float switch as shown.

COMBO UNIT INSTALLATION

Suggested Materials Needed:

Screwdriver, tape measure, hacksaw, and cable ties.

1. Drain the sump pit as far as possible without running the

pump dry. Do this by:

Piggyback switch: Unplug the pump and switch from

the outlet, then unplug the pump from the piggyback

switch. Reset the circuit breaker or reinstall the fuse

and plug the pump directly into the outlet. The pump

will start. Drain the pit and unplug the pump. OR

No piggyback switch: Reset the circuit breaker or

reinstall the fuse and use a non-conducting broom

handle or stick to raise the float switch; the pump

should start. Drain the pit and then release the

switch.

When the pit has drained, turn off (open) the circuit breaker or

remove the fuse again to avoid electrical shock while working

on the installation. Unplug existing sump pump and place

power cord and piggyback switch out of the way of work and

water.

2. Measure height of FG-3100RC Combo Kit from base to top

of hose clamp assembly. Subtract 1”.

Drop the tape measure into the bottom of sump pit and

mark the cut line on the discharge pipe (1” less than total

height of the Combo Kit).

3. Use hacksaw to cut horizontally along cut line completely

through pipe.

Note

:

Depending on where your current check valve is

located, there may be excess water. Let the water drain/

drip into the sump pit.

4. Remove old sump from sump pit.

Note

:

Remove all sand, clay, and gravel before installing.

5. Place Combo Kit into sump pit. Make sure vertical float

switches can operate freely inside sump pit.