Series 1572-SPX & 1573-SPX

Gas Engine-Driven, Self-Priming

Centrifugal Pump

Installation, Operation, Repair and Parts Manual

Description

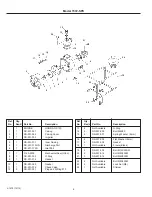

Form L-1474

(12/12)

California Proposition 65 Warning --

This product

and related accessories contain chemicals known to the

State of California to cause cancer, birth defects or other

reproductive harm.

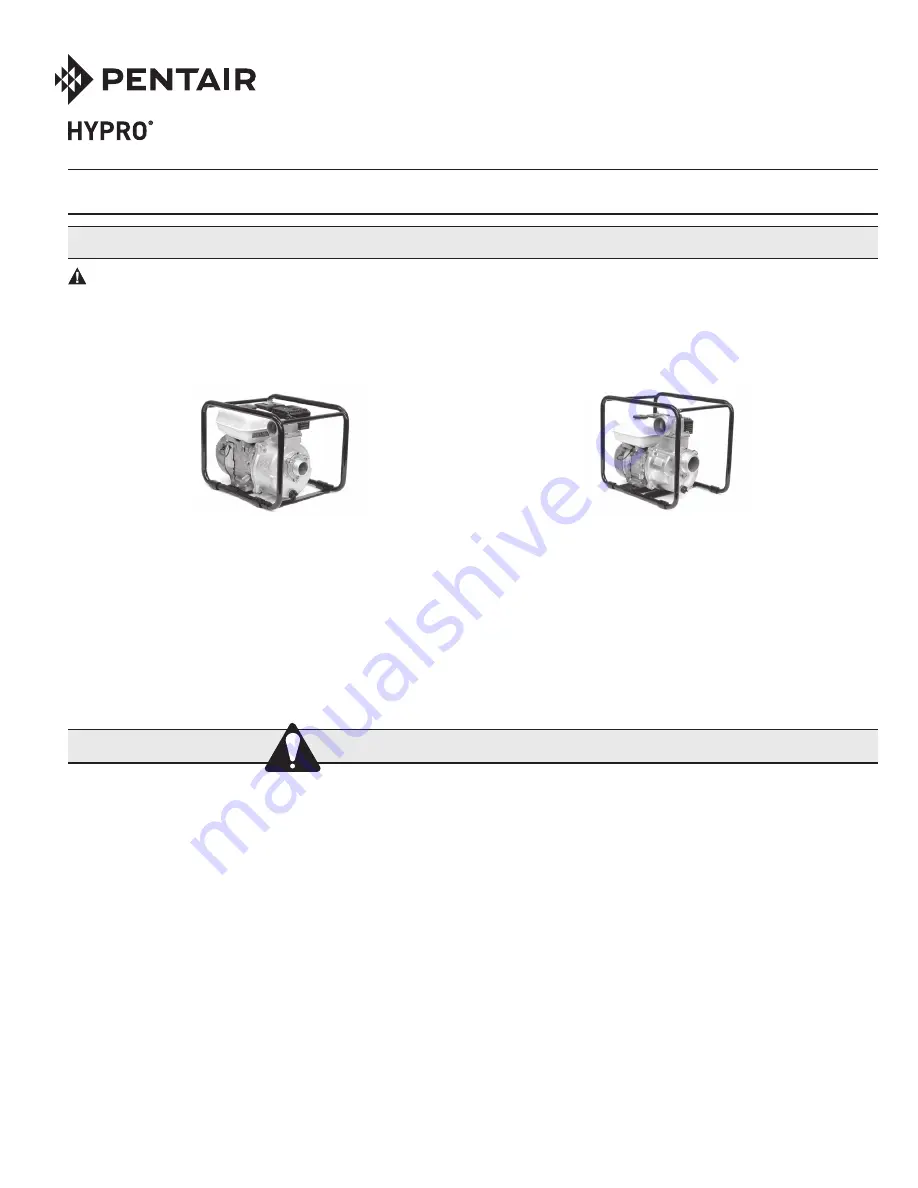

Hypro Self-Priming Centrifugal Pumps handle big, high-

capacity, liquid transfer jobs with ease. Use them for

transferring water, liquid fertilizers, and other chemicals

compatible with pump materials. Make short work of other

farm jobs: filling nurse tanks, watering seedbeds, and

transferring liquids. This self-priming model makes it ideal

for de-watering applications.

1572-SPX

Close-Coupled, Gas Engine-Driven

Self-Priming Centrifugal Pump

Max Flow Rate: ............................. 145 gpm

Max. Pressure: ..................................50 psi

Max. Total Head ............................... 115 ft.

Max. Suction Lift: ................................ 28 ft.

Ports: ........................................ 2” NPT Inlet

2” NPT Outlet

Engine ...................................Honda GX120

1573-SPX

Close-Coupled, Gas Engine-Driven

Self-Priming Centrifugal Pump

Max Flow Rate: .......................... 280 gpm

Max. Pressure: ...............................50 psi

Max. Total Head ............................ 115 ft.

Max Suction Lift: .............................. 28 ft.

Ports: .....................................3” NPT Inlet

3” NPT Outlet

Engine ............................... Honda GX160

WARNING: Do not pump flammable or explosive fluids

such as gasoline, fuel oil, kerosene, etc. Do not use

in explosive atmospheres. The pump should be used

only with liquids that are compatible with the pump

component materials. Failure to follow this warning

can result in personal injury and/or property damage

and will void the product warranty.

1. DO NOT EXCEED recommended speed, pressure and

temperature (140˚ F) for pump and equipment being

used.

2. BEFORE SERVICING, drain all liquids from the system

and flush. Remove the spark plug wire from the spark

plug before servicing the pump or engine.

3. Secure the discharge lines before starting the pump. An

unsecured line may whip, causing personal injury and/

or property damage.

4. Check hose for weak or worn condition before each

use. Make certain that all connections are tight and

secure.

5. Periodically inspect the pump and the system

components. Perform routine maintenance as required

(see Maintenance section).

6. Protect pump from freezing conditions by draining liquid

and pumping a permanent-type automobile antifreeze

containing a rust inhibitor through the system, coating

the pump interior. A 50% mixture with water is

recommended.

7. Do not operate a gasoline engine in an enclosed area.

Be sure the area is well ventilated.

WARNING: Gasoline is a highly combustible fuel. The

improper use, handling, or storage of gasoline can be

dangerous. Never touch or fill a hot engine.

8. Use only pipe, hose and fittings rated for the maximum

psi rating of the pump.

9. Do not use these pumps for pumping water or other

liquids for human or animal consumption.

General Safety Information