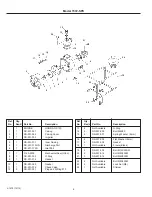

Model 1573-SPX

Ref. Qty.

No.

Req’d. Part No.

Description

1 ENGINE

HONDA GX160

1

1

DS-801-001

Casing

2

1

DS-501-004

Casing Cover

3

1

DS-801-009

Impeller

4

1

DS-801-011

Inner Casing

5

1

DS-801-019N

Discharge Port

6

1

DS-801-013N

Inlet Port

7

1

2120-0036

Mechanical Seal (Viton)

8

1

DS-501-002

O-Ring

9

1

DS-801-012

Gasket

10 1 DS-801-020

Gasket

11

1

DS-801-015

Check Valve

12

2

DS-501-021

Plug and O-Ring #13

Ref. Qty.

No.

Req’d. Part No.

Description

13

2

Not Available

O-Ring

14

4

DS-501-005

Bolt M8X48

15

4

DS-501-007

Spring Washer (8mm)

16

4

DS-501-008

Flat Washer (8mm)

17 4 DS-501-006

Gasket

18

1

DS-801-030N-2

Frame (Black)

19

4

DS-501-003

Bolt M10X30SW

20

4

DS-501-014

Bolt M8X25SW

21

3

DS-801-014

Bolt M8X30SW

22

4

Not Available

Bolt M8X40SW

23

4

Not Available

Lock Nut (M8)

24 1 DS-801-029

Strainer

7

14

16

17

15

20

13

12

5

10

21

11

13

19

1

4

3

7

8

2

9

6

18

23

22

24

12

L-1474 (12/12)