-225ML

-250ML

-275ML

-200ML

-900ML

1000ML

-525ML

-550ML

-575ML

-625ML

-650ML

-725ML

-825ML

-775ML

-750ML

-675ML

-850ML

-875ML

-925ML

-950ML

-975ML

200ml

1000ml

-500ML

-450ML

-475ML

-425ML

-400ML

-375ML

-600ML

-700ML

-800ML

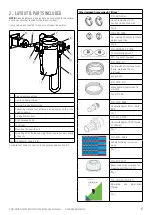

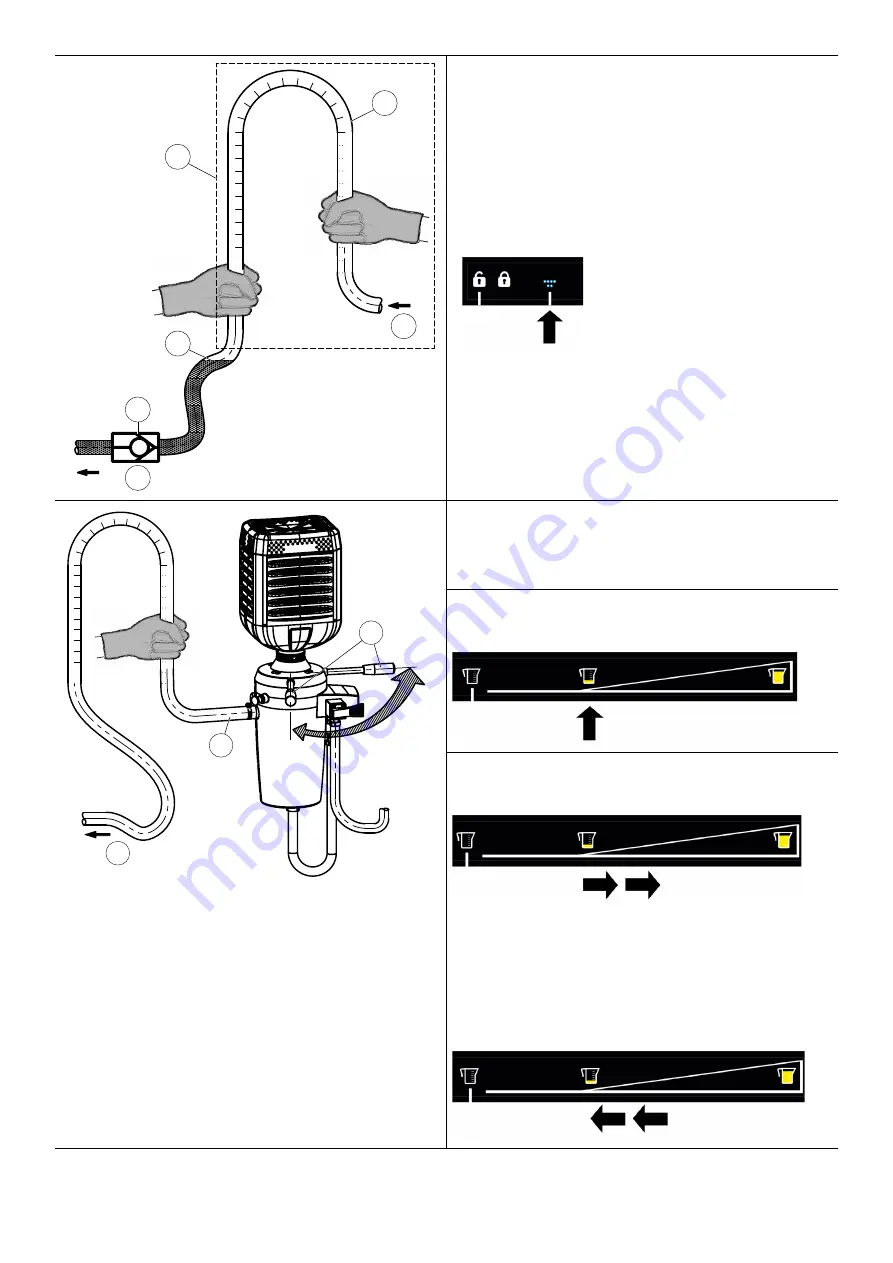

1

A

3

2

B

C

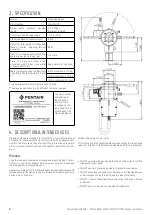

NOTE

: Prior to measuring chemical, it is recommended to practice

controlling the flow using a container filled with water.

At very high suction, the flow can prove difficult to control, so it

is recommended to reduce the pump speed thereby decreasing

suction. The optimum suction for partial dosing is –0.4 bar.

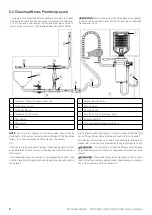

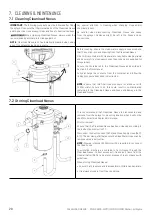

To measure using the scale marked on the Suction Hose, first

ensure the hose is fully drained of any liquid.

With suction drawing from the Cleanload Nexus and the Operating

Handle at the Lock Release Knob position and the droplet image

as shown:

Lower the Suction Hose below the Hosetail Outlet until any residual

liquid (Ref 3) drains beyond the check valve (Ref 2).

Then raise the Calibrated Suction Hose (Ref. 1) back above the

Hosetail Outlet and identify the required calibration marking on the

hose, hold the hose in the left hand at that calibration mark.

A - From Cleanload Nexus

B - To sprayer suction

Min.

Max.

-800ML

-700ML

-600ML

-375ML

-400ML

-425ML

-475ML

-450ML

-500ML

1000ml

200ml

-975ML

-950ML

-925ML

-875ML

-850ML

-675ML

-750ML

-775ML

-825ML

-725ML

-650ML

-625ML

-575ML

-550ML

-525ML

1000ML

-900ML

-200ML

-275ML

-250ML

-225ML

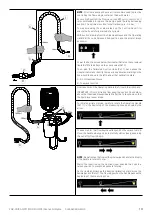

11

4

A

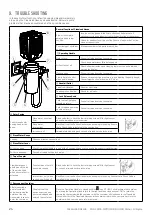

Now take hold of the Operating handle (Ref.11) with the right hand.

IMPORTANT: Prior to initiating flow, keep the Suction Hose held up

above the Cleanload Nexus Hosetail Outlet (Ref. 4) as shown so that

the liquid level never drops.

To initiate partial emptying, carefully rotate the Operating Handle

(Ref. 11) to the beginning of the measuring zone as shown by the

arrow.

The exact point that flow begins will depend on the sprayer set up.

Move the handle slowly and incrementally while closely observing

the outlet for flow to begin.

NOTE

: Be patient as the flow will begin slowly and can start abruptly

if the handle is rotated too far.

Watch the level rise up the Suction Hose, keeping the hose in a

raised position to prevent air pockets forming.

As the liquid approaches the desired calibration mark, move the

handle back to the left. The flow stops when the handle passes the

beginning of the measuring zone.

CLEANLOAD NEXUS

PNR-CN100-OIPM (10/12/21) ©2021 Pentair. All Rights.

13