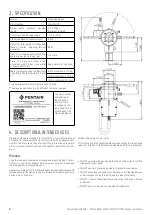

1. SAFETY INFORMATION

READ THESE INSTRUCTIONS AND THEN KEEP THEM FOR

REFERENCE: This manual contains important instructions that

should be followed during installation, operation and routine

maintenance of Cleanload Nexus.

SAFETY SYMBOLS

This is the safety alert symbol. When you see this symbol do

not ignore it! Look for one of the following signal words and be alert

to the potential for personal injury:

!

DANGER

Warns about hazards that could cause serious

personal injury, death or major property damage.

!

WARNING

Warns about hazards that could cause serious

personal injury, death or major property damage.

!

CAUTION

Warns about hazards that could cause serious

personal injury or property damage.

The word

NOTE

indicates special instructions that are important

but not related specifically to hazards.

GENERAL SAFETY

Carefully read and follow all safety instructions in this manual

and on the Cleanload Nexus itself. Failure to comply with the

safety/operating instructions could result in personal injury and/

or property damage and could lead to the loss of any claims for

damages.

Ensure that you understand the Cleanload Nexus applications,

limitations, and potential hazards. Keep safety labels fixed to

Cleanload Nexus and in good condition. Replace any missing or

damaged labels.

!

WARNING

The mounting and connections of Cleanload

Nexus must be done by professionals who are trained in repair

and maintenance of the sprayer.

∙

!

WARNING

For mounting on the sprayer only use hoses

and fittings that meet the recommended specifications of the

sprayer manufacturer.

∙

Only use pipe, hose, and hose fittings that have not been used

before and meet the stated maximum pressure ratings of the

Cleanload Nexus. Check all hoses for weakness or signs of wear

before each use.

∙

!

WARNING

Regulations and recommendations for personal

protective equipment (PPE) must be complied with.

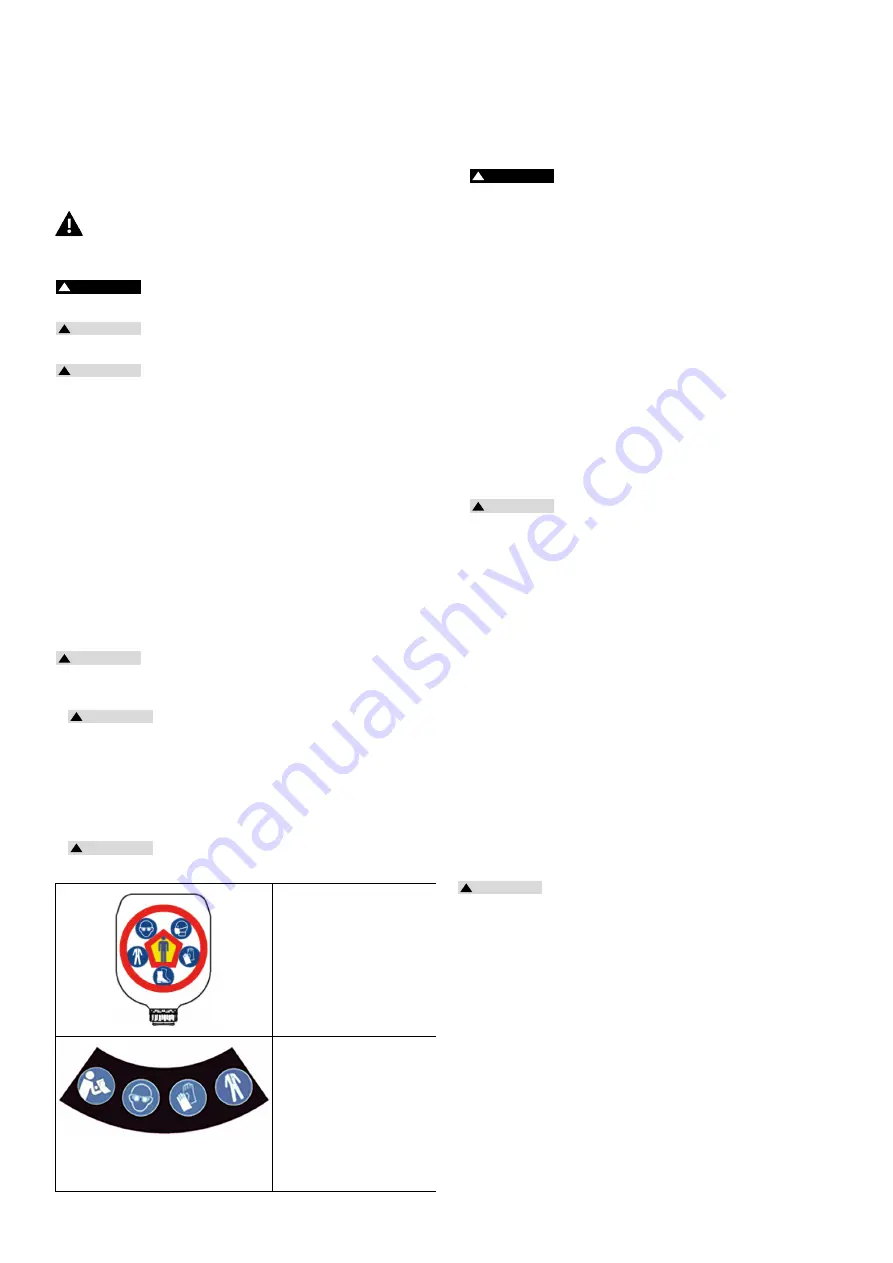

When operating

Cleanload Nexus use

the Personal Protective

Equipment (PPE) that is

recommended on the

agrochemical label.

If

no

specific

PPE

is required by the

agrochemical label wear

gloves, protective glasses

and a chemical resistant

apron or overall when

operating, maintaining

or servicing Cleanload

Nexus.

Before using Cleanload Nexus:

∙

Ensure that the Cleanload Nexus is mounted securely on the

sprayer or other mounting location.

∙

Always comply with regulations when choosing a suitable site for

filling the sprayer with chemical.

∙

!

DANGER

Ensure that all hoses are securely connected,

that the sprayer’s suction is operating and that the Umbrella

Valves are in place

∙

Only use containers that are fitted with an easyconnect cap. Do

not remove and refit the cap to any other container except a

container of water or cleaning agent that is used for cleaning the

Cleanload Nexus as directed in this manual.

∙

Do not operate Cleanload Nexus at pressures outside of the

range given in this manual.

∙

Only operate Cleanload Nexus at temperatures between 0° and

60°C (32° to 140°F).

∙

Do not attempt to transport or move Cleanload Nexus with a

chemical container connected.

∙

Defective components and assemblies must be replaced

immediately. Use original spare parts for replacement only.

After using Cleanload Nexus:

∙

!

CAUTION

Always clean the Cleanload Nexus according to

the instructions.

∙

Comply with regulations on cleaning sprayers when cleaning the

Cleanload Nexus.

∙

Do not leave concentrated agrochemicals in the Cleanload Nexus

for extended periods after carrying out a transfer.

∙

Store Cleanload Nexus under protected, frost-free conditions

and inaccessible to children and animals at all times.

∙

For winter storage or if freezing conditions are anticipated, clean

the Cleanload Nexus according to instructions then additionally

pass a 50/50 mixture of water and antifreeze through.

∙

Fit the Top Cover to protect Cleanload Nexus when not in use.

∙

Check if there is leakage from any part of the Cleanload Nexus or

connecting hoses or if the handle is very difficult to rotate and

rectify before next use.

∙

Do not attempt to maintain or repair Cleanload Nexus without the

required training, tools and parts as any substitute could result in

damage and failure of the Coupler. Instructions for maintenance

and service are included in the Service and Maintenance Manual

!

CAUTION

Hazardous substances alert

1. Always drain and clean Cleanload Nexus before storage,

servicing or disassembling for any reason.

2. Always drain and clean Cleanload Nexus prior to returning to a

service agent for maintenance or repair.

3. Before attempting to carry out any maintenance or repair, make

sure that you are wearing appropriate PPE.

CLEANLOAD NEXUS

PNR-CN100-OIPM (10/12/21) ©2021 Pentair. All Rights.

4