1

2

3

4

5

6

7

8

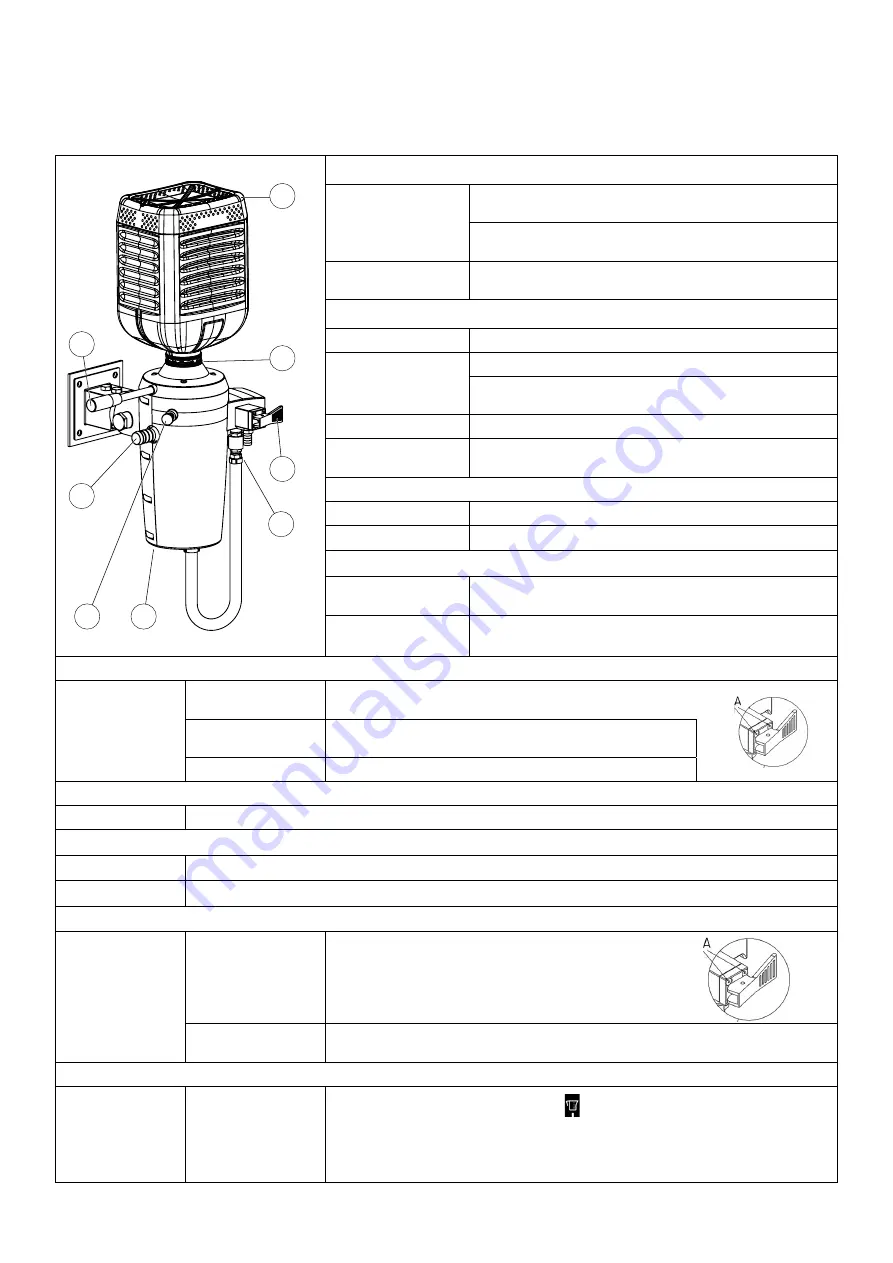

General Function of Cleanload Nexus

Slow or incomplete

emptying due to low

suction.

Insert a suction gauge in the line to check suction pressure, if

necessary review the industor (venturi) specification of the sprayer.

Check for obstruction of the suction line or air leaks in the Suction

Hose or connections.

Poor rinsing of container

or cap.

Rinse pressure must be a minimum 3.5 bar.

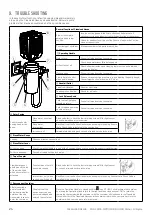

①

Operating Handle

Hard to turn.

Consult a trained service technician.

Will not turn at all.

Check rinse water lever (6) is not engaged.

Check chemical residue and cleaning regime or consult a trained

service technician.

Makes a noise.

Consult a trained service technician.

Flow is hard to control

when partial dosing.

Reduce sprayer suction pressure, e.g. by adjusting the pump speed,

the optimum suction for dosing is -0.4 bar.

②

Hosetail Outlet

Leak from Hosetail.

Secure hose clamp.

Foaming in suction line.

Check for air leaks.

③

Lock Release Knob

Fails to stop Operating

Handle on return.

Consult a trained service technician.

Fails to release operating

handle on return.

Consult a trained service technician.

④

Outer Casing

Leak through outer

casing, seen at the

base.

Rinse water, constant

flow.

Rinse valve fault, check the four retaining screws (A) for tightness or

consult a trained service technician.

Rinse water,

intermittent.

Back flow from the Suction Hose may be escaping into casing. Ensure

that a Check Valve is installed in the suction line.

Is it chemical?

Immediately stop using and consult a trained service technician.

⑤

Rinse Water Hoses

Leaking.

Check and tighten connections.

⑥

Rinse Water Lever

Will not engage.

Check Operating Handle is in one of the 2 rinse positions or or consult a trained service technician.

Will not disengage.

Consult a trained service technician.

⑦

Top of Coupler

Liquid emerges or

pools around the top

of the probe head

when no container is

attached.

Constant when there is

rinse water supply.

Rinse valve fault, check the four retaining screws (A) for tightness or

or consult a trained service technician

Intermittent, only when

suction is switched off.

Back flow from the Suction Hose may be escaping into casing. Ensure that a Check Valve is

installed in the suction line.

⑧

Easyconnect Container

After measuring a

partial container,

and when rinsing the

outside of the cap,

rinse water is seen to

enter the container.

The plug from the

easyconnect cap has

become dislodged and

entered the container

Move the Operating Handle to closed position

then EITHER: Fully discharge the container

by moving the Operating Handle fully to the right and then rinse as usual. OR

:

T

o retain the

remaining contents inside the container, with the container still locked onto the Cleanload

Nexus invert both the Cleanload Nexus and the container to drain the contents back into the

container which can then be carefully removed.

9. TROUBLESHOOTING

In the event of malfunction or a fault developing, please immediately

stop using the Cleanload Nexus and seek advice. Below are some

problems that may be encountered and their possible causes.

CLEANLOAD NEXUS

PNR-CN100-OIPM (10/12/21) ©2021 Pentair. All Rights.

24