37

IntelliFlo VS+ SVRS Installation and User’s Guide

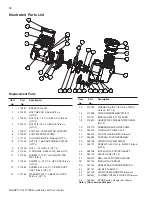

Pump Disassembly

WARNING —

Always disconnect power to the pool pump at the circuit breaker and disconnect the

communication cable before servicing the pump. Failure to do so could result in death or

serious injury to serviceman, pool users or others due to electric shock.

Read all servicing instructions before working on the pump.

WARNING — DO NOT

open the strainer pot if pump fails to prime or if pump has been operating without

water in the strainer pot. Pumps operated in these circumstances may experience a build up

of vapor pressure and may contain scalding hot water. Opening the pump may cause serious

personal injury. In order to avoid the possibility of personal injury, make sure the suction and

discharge valves are open and strainer pot temperature is cool to touch, then open with

extreme caution.

CAUTION —

Be sure not to scratch or mar the polished shaft seal faces; seal will leak if faces are

damaged.

All moving parts are located in the rear subassembly of the IntelliFlo VS pump.

Tools required:

•

3/32 inch Allen head wrench.

•

½ inch open end wrench.

•

9/16 inch open end wrench.

•

Flat blade and phillips head screwdriver

To remove and repair the pump mechanical seal, perform the following procedures:

1. Switch off the pump circuit breaker at the main panel.

2. Disconnect the RS-485 communication cable from the pump.

3. Drain the pump by removing the drain plugs.

4. Remove the six bolts that hold the main pump body (strainer pot/volute) to the rear subassembly.

5. GENTLY pull the two pump halves apart, removing the rear subassembly.

6. Use a 3/32 inch Allen head wrench to loosen the two holding screws located on the diffuser.

7. Hold the impeller securely in place and remove the impeller lock screw by using a Phillips head

screwdriver. The screw is a left-handed thread and loosens in a clockwise direction.

8. Use a flat blade screwdriver to hold the motor shaft. The motor shaft has a slot on the end which is

accessible through the center of the fan cover.

Initial SVRS Setup and Operational Check

(Continued)

4. The pump should be started and operated at the maximum intended flow or speed for the system. An

external flow meter may be required.

5. At the maximum flow condition, check the vacuum reading on the vacuum gage. If the reading is

greater than 25 inches of mercury (Hg) then the speed will need to be reduced to limit vacuum to

25 " Hg.

6. If the system requires speed limitations, it’s recommended that the pump maximum speed be adjusted,

see “Maximum Speed,” page 12 for details. The pump should also be password protected (see “Setting

Password” page 14 and 15) ,

7. After the system setup, a check should be performed that simulates an entrapment event, refer to

“Suction Blockage” page 43 for a description of two potential checking methods.