5

SandShark

™

Installation and User’s Guide

Optional Installation

WARNING

—

Suction entrapment, injury, and drowning hazard.

If your pool has a dedicated suction port

(“vac port”) for vacuuming or for an automatic pool cleaner, it must be covered when not in use.

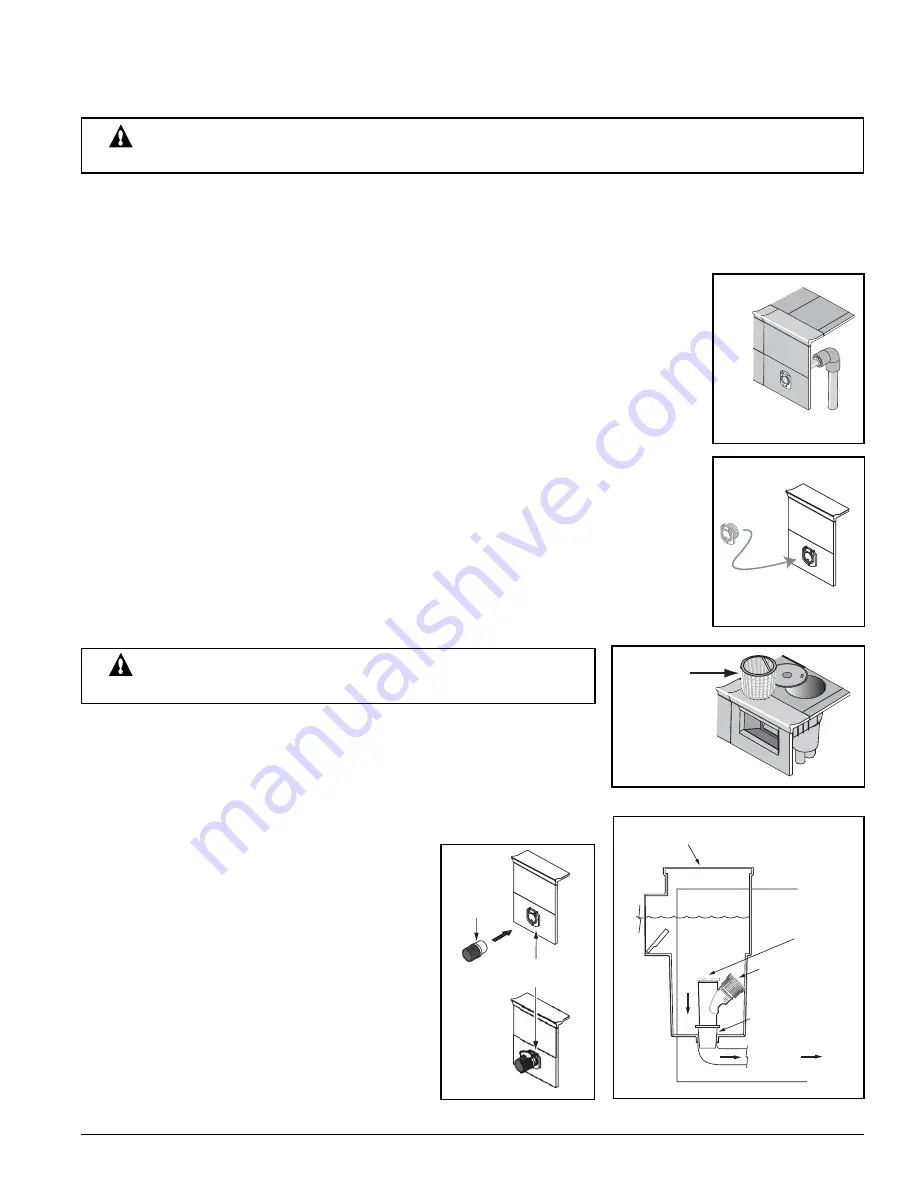

Vac Port Installation with Vacuum Regulator in Skimmer

If your pool has a dedicated wall fitting “vac port”, (see Figure 16), you can install the SandShark

™

using the

Optional Installation

.

1. Turn the pool pump off.

2. Adjust valves for vacuuming. Adjust the pump valves (if your system has valves)

to direct all suction to the dedicated vacuum line and the skimmer. Close the main

drain and all remaining suction lines, except the line from the dedicated vacuum line

to which your SandShark

™

cleaner will be connected, and the skimmer where the

vacuum regulator will be installed.

3. A spring loaded safety cover, (“vac port fitting”), is included with this pool cleaner

(see Figure 17). Install it on the dedicated vacuum line to prevent entrapment and

injury. For details please refer to the

Vac Port Instruction sheet

included with your

vac port fitting. To install the included vac port fitting:

a. Screw the vac port fitting into the dedicated vacuum line opening.

b. Orient the vac port fitting so the arrow on the door points up.

c. Secure the cover by tightening the Allen-screw below the door, into the dedicated

vacuum line fitting.

4. Remove the skimmer basket from the skimmer, (see Figure 18).

WARNING

—

Hazardous suction.

Can cause entrapment with severe

personal injury or drowning.

5. Insert the vacuum regulator and reducer cone in the skimmer,

(see Figure 19). To prevent water from flowing through the top of the

vacuum regulator, attach the regulator cap to the vacuum regulator.

6. Attach the end of the hose to the vac port fitting installed in the

dedicated vacuum line, (see Figure 20).

Figure 16.

Vac

Po

r

t

Figure 17.

Skimmer

Ba

ske

t

Figure 18.

Skimmer

Vacuu

m

R

e

gulato

r

R

e

gulato

r

Cap

To Pu

m

p

R

e

duc

er

Con

e

Figure 19.

H

o

se

End

Vac Po

r

t

F

i

tt

i

ng

Figure 20.

Summary of Contents for Kreepy Krauly SandShark 7900

Page 22: ...16 SandShark Installation and User s Guide NOTES...

Page 23: ...SandShark...

Page 24: ...P N 39503 6300 Rev A 10 27 08...