6

SandShark

™

Installation and User’s Guide

Optional Installation,

cont’d.

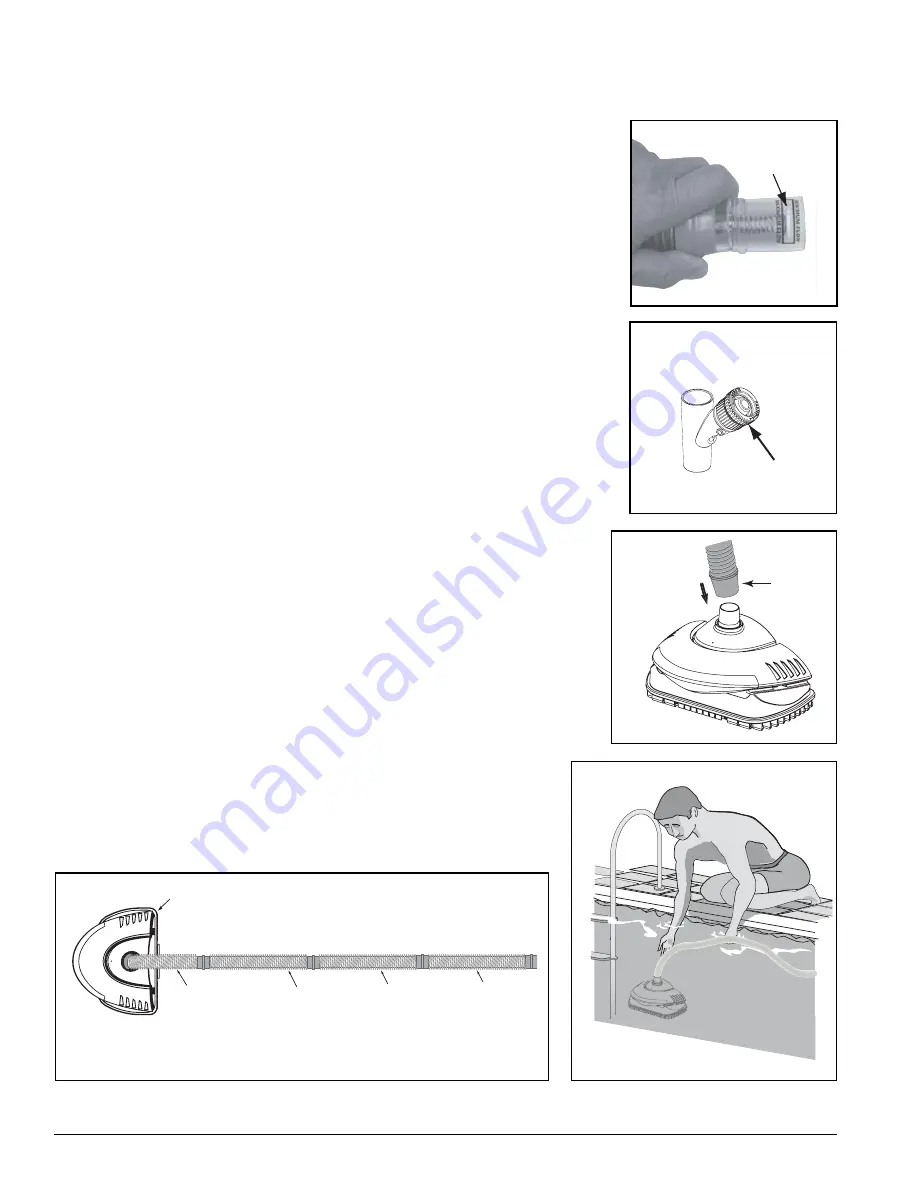

Adjust Flow

1. With the main drain closed, and one end of the hose attached to the vacuum

regulator installed in the skimmer, insert the flow gauge into the other end of

the hose (the end with the “leader” hose attached).

2. Keep the hose and flow gauge underwater.

3. Turn on the pump. With the pump running, adjust the vacuum regulator

(in your skimmer) until the indicator on the flow gauge is between minimum and

maximum flow (Figure 21).

4. Use the vacuum regulator in conjunction with your pool cleaner system at all

times. The vacuum regulator has an adjustment knob, (see Figure 22). If

suction is too high, the knob is turned counterclockwise to decrease the

suction. If the suction is too low, the knob is turned clockwise to increase the

suction.

NOTE: The flow gauge is calibrated for use with the “Y” shaped vacuum

regulator valve. The flow gauge will not indicate the correct flow for the

cleaner if you are not using the “Y” shaped vacuum regulator valve.

5. Remove the flow gauge from the end of the hose (the end with the “leader”

hose attached) and attach the “leader” hose to the cleaner’s swivel.

Connect the Hose to the Cleaner

1. Connect the leader hose to the cleaner (correct end of hose is marked

with a red label), (see Figure 23).

2. Fill the cleaner with water and let it sink to the bottom, (see Figure 24).

3. Verify hose connections as shown in Figure 25.

Disc Indicator

Figure 21.

Flow Indicated on Flow Gauge.

Le

ad

er H

o

se

m

a

rke

d

"

Conn

e

ct

to

Cl

e

an

er"

Figure 23.

Figure 24.

S

and

S

ha

rk

cl

e

an

er

Th

e

ho

se

m

u

s

t

e

qual th

e

long

es

t d

is

tanc

e

f

r

o

m

th

e

s

uct

i

on conn

e

ct

i

on

to th

e

fu

r

th

es

t po

i

nt

i

n th

e

pool, plu

s

on

e

ho

se

se

ct

i

on l

e

ngth,

plu

s

th

e

12

i

n. l

e

ad

er

ho

se

.

S

ho

r

t, 12

i

n.

Le

ad

er

ho

se

must be

installed

Se

cond ho

se

Se

ct

i

on

Th

ir

d ho

se

Se

ct

i

on

Fou

r

th ho

se

Se

ct

i

on

Figure 25.

Figure 22.

Vacuum

Regulator

Adjustment

Knob

Summary of Contents for Kreepy Krauly SandShark 7900

Page 22: ...16 SandShark Installation and User s Guide NOTES...

Page 23: ...SandShark...

Page 24: ...P N 39503 6300 Rev A 10 27 08...