4

READ AND FOLLOW SAFETY INSTRUCTIONS!

This is the safety alert symbol.

When you see this

symbol on your pump or in this manual, look for one of the

following signal words and be alert to the potential for

personal injury:

DANGER

warns about hazards that will cause serious

personal injury, death or major property damage if ignored.

WARNING

warns about hazards that can cause serious

personal injury, death or major property damage if ignored.

CAUTION

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The label

NOTICE

indicates special instructions which are

important but not related to hazards.

Carefully read and follow all safety instructions in

this manual.

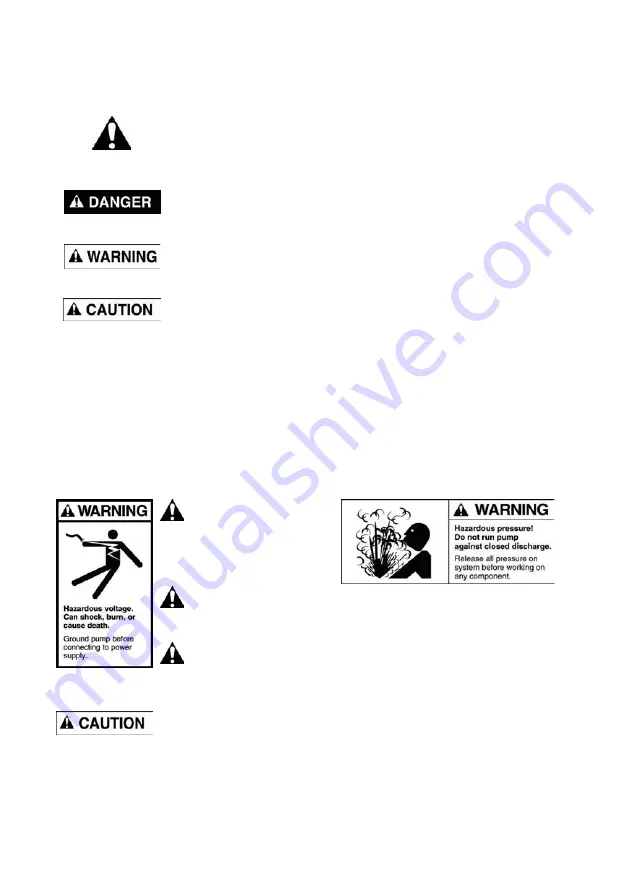

Electrical Safety

Wire motor for correct

voltage. See

‘Electrical’ section of

this manual and

motor label.

Ground motor before

connecting to power

supply.

Meet National or local

electrical code for all

wiring.

Do not touch an operating motor. Modern motors

are designed to operate at high temperatures. To

avoid burns when servicing pump, allow it to cool

for at least 20 minutes after shut-down before

handling.

General Safety

To avoid heat build-up, over pressure hazard and

possible injury, do not use in a pressure tank

(domestic water) system. Do not use as a booster

pump; pressurised suction may cause pump body to

explode.

Do not allow pump or piping system to freeze.

Freezing can damage pump and pipe, may lead to

injury from equipment failure and will void warranty.

Pump water only with this pump.

Periodically inspect pump and system components.

Wear safety glasses at all times when working on

pumps.