32

SECTION 6: Pentek

®

6” Submersible Motors

6.7 Overload Protection

Submersible motors must have Class 10 overload protection that will disconnect the power within 10 seconds in the

case of a locked rotor. To accomplish this, fixed-heater overloads are used. Refer to Section 10 for appropriate heaters.

The chart is based upon total line amps. Divide the motor amps by 1.732 when using a 6-lead motor with a Y-Delta

Starter. Notice: General Electric overload heaters are only usable with general electric overload relays. Do not adjust

relays to exceed nameplate amps.

6.8 Motor Cooling

Pentek 6” motors are designed for minimum water flow of 0.5 ft. /sec. past the motor. Maximum water temperature is

95° F (35° C).

6” MOTORS: MINIMUM COOLING WATER FLOW

I.D of casing

Flow (GPM) required

6

9

7

25

8

40

10

85

12

140

14

200

16

280

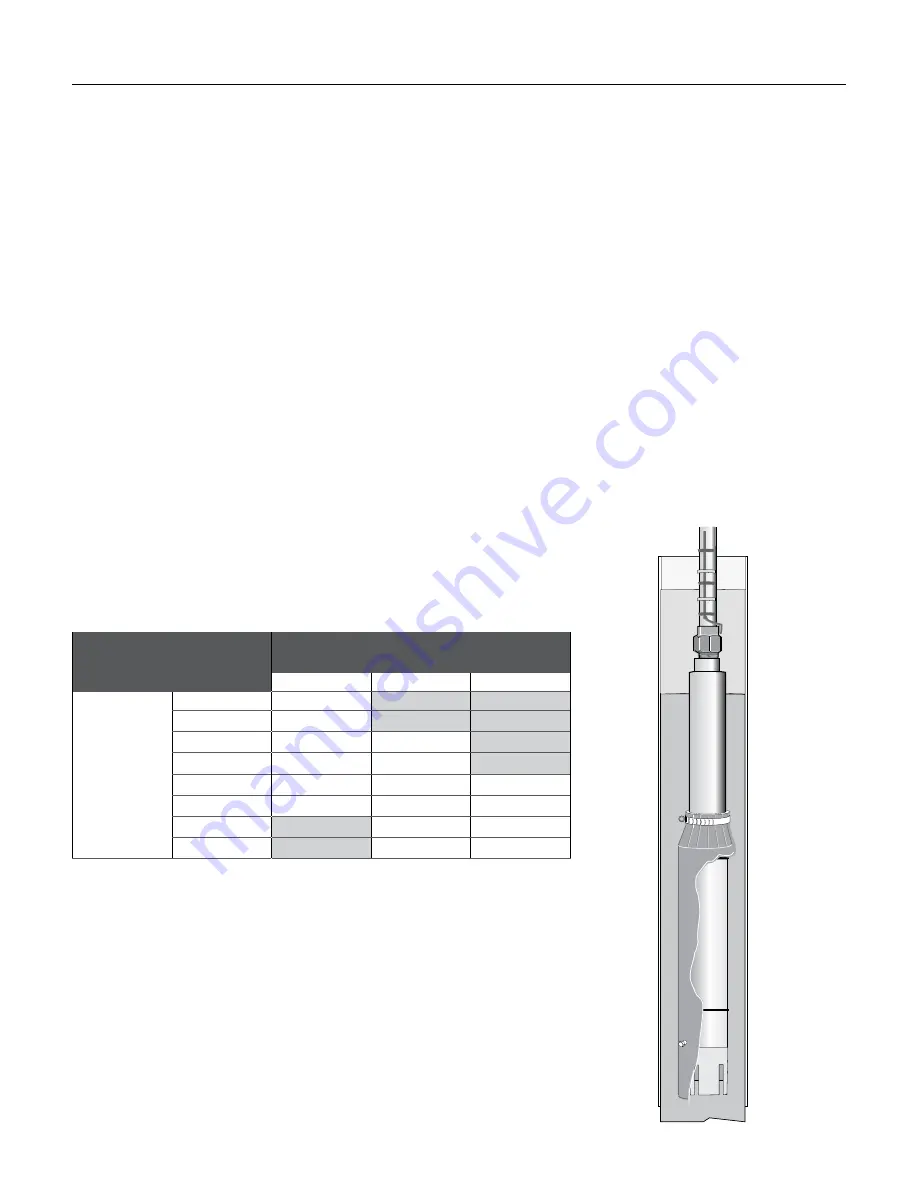

If the flow is less than specified, a flow-inducer sleeve can be installed. This will act like a smaller casing size, and

force flow around the motor to aid cooling. Always use a flow-inducer sleeve when the pump is in open water.

6.9 Head Loss In Casing

Use the chart below to account for the head loss around the pump.

6.10 Starting Frequency

To extend the life of the pump motor and control, limit the number of starts

to 100 per 24 hours. If higher starting frequencies are necessary, consult

your factory. To prevent overheating, run motor for a minimum of two

minutes. For starting frequency, refer to section 5.10.

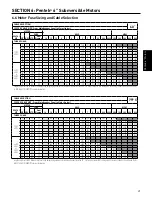

Head loss in feet for flow past motor

6” Motors

cAsiNg iNside diAMeter

6”

7”

8”

gPM

100

1.7

150

3.7

200

6.3

0.5

250

9.6

0.8

300

13.6

1.2

0.2

400

23.7

2.0

0.4

500

3.1

0.7

600

4.4

1.0

Summary of Contents for P42B0007A2-01

Page 1: ...pentek Electronics Manual Installation Operation Maintenance WWW PUMPS COM ...

Page 108: ...NOTES ...

Page 109: ...NOTES ...