89

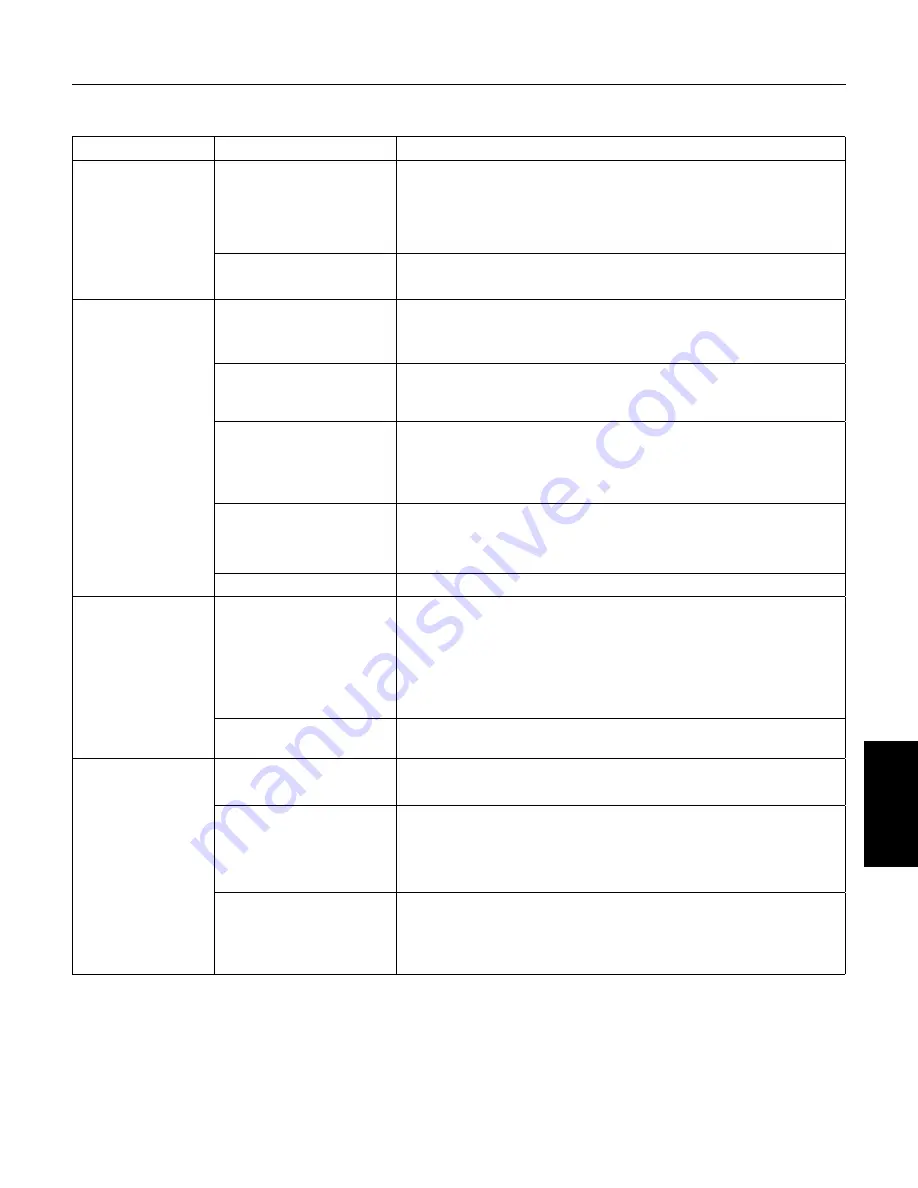

Troubleshooting

13.1 Pump And Motor Problem Analysis

Problem

Possible Cause

Check And Restore

Pump Won’t Start.

No voltage (check

with voltmeter).

Typically will be no

startup noise.

1. Main power supply off.

2. Blown fuse or tripped circuit breaker.

3. Wiring damage, loose connection.

4. Burnt contactor points.

Locked pump.

1. Check for sand in system.

2. Crooked well (submersible)

Overloads Trip.

Low or high voltage.

1. Check with voltmeter. (±10% of nameplate voltage). Request

power company correct problem.

2. Determine if wire size is correct for voltage and amperage.

Hi gh ambient

temperature or direct

sunlight.

1. Improve cooling for motor and controls.

2. Use ambient compensated overloads.

In correct pump sizing –

mismatched motor.

1. Check pump (gpm) make sure near B.E.P. - “Best Efficiency

Point”.

2. Recheck pump and motor model numbers prior to installation.

Keep a written record.

High cycling rate.

1. Pressure control equipment malfunction.

2. Hole in piping system.

3. Pressure/storage tank failure.

Damaged motor control.

Check components per troubleshooting.

Fu ses Blow or

Breaker Trips.

Short or Ground.

1. Fuses give superior protection and should be used in preference

to circuit breakers when possible.

2. Inspect wiring for visible signs of heat damage (discoloration,

damage to insulation).

3. Disconnect power and check with ohmmeter or megohmmeter

to ground.

Improper sizing.

Consult manufacturer’s information / sizing chart for proper size

and replace as required.

Lo w or No Water

Production.

No rotation.

1. Motor not turning (see “Pump won’t start” above.

2. Broken shaft coupling. Ammeter will show “low” amps.

Restriction in piping.

1. Check valve sticking.

2. Check valve installed backward.

3. Broken check valve poppet or flapper lodged in piping system

downstream.

Plugged inlet.

1. Intake screen encrusted with minerals.

2. Insufficient clearance between pump and well casing for high

capacity pump. Calculate intake velocity and limit to less than

5 feet per second.

SECTION 13: Troubleshooting

Summary of Contents for P42B0007A2-01

Page 1: ...pentek Electronics Manual Installation Operation Maintenance WWW PUMPS COM ...

Page 108: ...NOTES ...

Page 109: ...NOTES ...