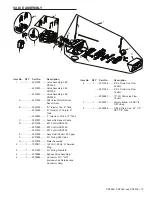

PRF26K, PRF34K, and PRF40K

Water Softening System

INSTALLATION INSTRUCTIONS

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 2-19

Repair Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 14

Manual de Sistema ablandador

de agua

INSTRUCCIONES DE INSTALACIÓN

Español . . . . . . . . . . . . . . . . . . . . . . . . . . Páginas 20-37

Piezas de repuesto . . . . . . . . . . . . . . . . . . . . . Página 32

Manuel

Adoucisseur d'eau

INSTRUCTIONS D’INSTALLATION

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 38-55

Piéces de Rechange . . . . . . . . . . . . . . . . . . . . . Page 50

Tools and Fittings Required

• Pipe Cutter

• Tubing Cutter

• File

• Pliers

• Tape Measure

• Soldering Tools

• Lead Free Solder

• Bucket

• Towel

• PTFE Pipe Tape

• Adjustable Wrench

• Tube 100% Silicone Grease

Outils et accessoires requis

• Coupe-tuyau

• Coupe-tube

• Lime

• Pince

• Mètre ruban

• Outillage de brasage

• Brasure sans plomb

• Seau

• Serviette

• Ruban pour tuyau en PTFE

• Clé ajustable

• Graisse de silicone à 100 %

pour tube

For further operating, installation, maintenance,

parts or assistance:

Call Technical Service at:

800.297.9404

Para obtener más información sobre el

funcionamiento, la instalación, el mantenimiento,

las piezas o para obtener asistencia:

Comuníquese con el Servicio de atención

al cliente al:

800.297.9404

Pour de tout autre renseignement concernant

le fonctionnement, l’installation ou l’entretien:

Appelez le service à la clientèle en com-

posant le : 800.297.9404

Herramientas y accesorios

necesarios

• Sierra para cortar tuberías

• Cortatubos

• Lima

• Pinzas

• Cinta métrica

• Herramientas para soldar

• Soldador libre de plomo

• Cubeta

• Toalla

• Cinta de PTFE para tubería

• Llave ajustable

• Tubo de grasa 100% de silicona

Tested and Certified by WQA to NSF/

ANSI Standard 44 & 372 for softener

performance & lead free compliance and

CSA B483 .1 .

Probado y certificado por la WQA

según la norma 44 y 372 de NSF/ANSI

por el desempeño del suavizador y el

cumplimiento del no contenido de plomo

y CSA B483 .1 .

Testé et certifié par WQA conforme

à la norme 44 et à la norme 372 de

NSF/ANSI pour la perfomance des

adoucisseurs et pour la conformité à

l'exemption de plomb et CSA B483 .1 .

FILTRATION & PROCESS

5730 NORTH GLEN PARK ROAD, MILWAUKEE, WI 53209

P: 262.238.4400 | 800.279.9404

www.pentairaqua.com