EQUIPMENT INSTALLATION

continued

Grounding the Plumbing

It is important that the plumbing system be electrically

grounded . When a water softener is installed a non-metalic

bypass valve may interrupt the grounding . To maintain

continuity, a grounding strap can be purchased at a hardware

store . When it is installed the strap will connect the plumbing

into the softener to the plumbing out of the softener .

If you have other water treating equipment such as; chlorinator,

sediment filter, neutralizer, iron filter, or taste & odor filter they

should be installed upstream of the water softener .

You may wish to consult a water professional if additional water

treating equipment is to be installed .

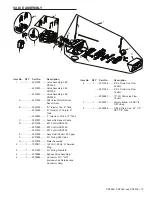

Valve Layout

Outlet 1" NPT

Inlet 1" NPT

Meter

Cable

Drain

1/2" Tube

To Brine Tank

3/8" NPT

Figure 5

Drain Line Flow Control

The drain line flow control (DLFC) requires assembly

(Figure 6) .

1 . Locate parts and a roll of Plumber's tape .The plumbing

adapters should be removed (Figure 8 Connector

Assembly) .

2 .

Wrap the tape over threads of the flow control.

3 .

Screw the flow control and the 90° elbow together. Hand

tighten .

4 .

Place the ball into the flow control and insert the assembly

into the drain line opening .

5 . Push the assembly in and secure with the drain line clip .

90° Elbow Flow Control

Control Ball

Drain Line Clip

Figure 6

Water Line Connection

A bypass valve system is included and will be installed on the

water conditioning system . Bypass valves isolate the softener

from the water system and allow unconditioned water to be

used . Service or routine maintenance procedures may also

require that the system is bypassed .

IMPORTANT: The bypass valve is shipped to you in the

bypass position (Figure 7 Bypass Operation). When the

valve is in bypass water will not enter the softening tank.

The water in the building will not be treated. Figure 7

Bypass Operation, shows the handles in the service

position.

Once you have selected your location check the direction of

the waterflow in the main pipe. Figure 7 Bypass Operation can

be used to plan the new plumbing assembly .

Inspect the main water pipe . Write down the type of pipe

(copper, plastic, galvanized etc .) . Record the size of the pipe .

Plastic style pipes usually have the size printed on the outside .

Other pipes can be measured for the outside diameter and

converted into the pipe size at the store . Do not use pipe that is

smaller than the main water pipe .

The bypass has two fittings that connect to the plumbing.

These connections are threaded 1" NPT .

If the main plumbing is galvanized pipe and you are installing

copper pipe, then you must use dielectric insulating connectors

between the two styles of pipe .

Place the two tanks in position . The design of the tank does not

allow for bad alignment of the connections . You may ask your

supply store about flexable connections.

Take measurements and create a drawing of your installation .

Include pipe lengths and elbows that are needed . If the water

flow is from right to left you will need to cross the plumbing to

the softener . Take the drawing to your plumbing supply store .

Consult with their expert for installation ideas and suggestions .

Assemble the plumbing .

WARNING:

If pipes will be sweat soldered, do not

connect adapters to the bypass until the

pipes have cooled.

IN

OUT

IN

OUT

Connector

Assembly

“H” Clip

Drain

Line

Handles in Service

Handles in Bypass

Figure 7 Bypass Operation

WARNING:

The inlet water must be connected to the

inlet port of the valve. When replacing

non-PRF Water valves, it is possible that

the inlet and outlet plumbing is installed

in a reversed position. Be certain the inlet

connection on the valve is connected to the

incoming water fitting from the water supply.

Do not solder pipes with lead-based solder.

WARNING:

Do not use petroleum grease on gaskets

when connecting bypass plumbing. Use

only 100% silicone grease products when

installing any plastic valve. Non-silicone

grease may cause plastic components to fail

over time.

PRF26K, PRF34K, and PRF40K • 7