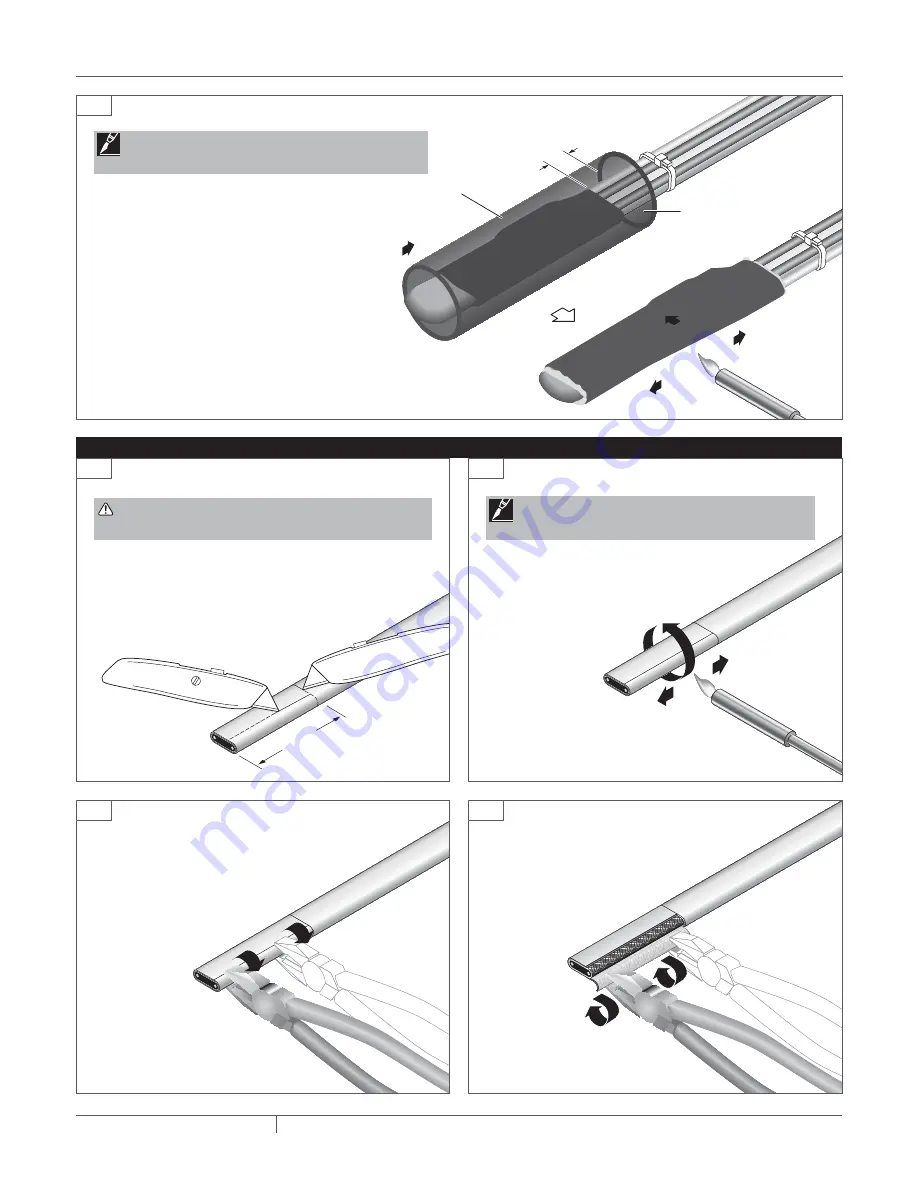

2 in

(51 mm)

1

3

4

2

• Allow 12 in (305 mm) of heating cable in junction box for

proper assembly.

• Score around outer jacket 2 in (51 mm) from end.

• Make one lengthwise score as shown.

• Use Ideal crimp tool No. 30-425 or blunt

nose pliers to pull outer jacket from braid.

• Gently heat cable to loosen bond

between outer jacket and braid.

• Roll outer jacket back around

heating cable to remove.

7 / 10

tHerMAl builDing solutions

Raychem-IM-H57284-EMKXP-EN-1612

½ in

(13 mm)

6 in (152 mm) tube

Heat this end first

24

• Position the 6 in (152 mm) long heat-

shrinkable tube (Item A) over the mastic sheet,

1/2 in (13 mm) from end of mastic sheet.

• Begin heating tube at end near cable tie.

• Heat until tube is recovered completely and

adhesive or mastic flows from ends.

• Continue to heat center section to melt mastic

inside but do not blister or burn tube.

• Allow the connection to cool before placing in

junction box.

note: see step 1 for proper heating techniques.

note: see step 1 for proper heating techniques.

end seal installation instructions

WArning: Do not cut into braid or inner jacket. this

could result in a short circuit.