THERMAL MANAGEMENT SOLUTIONS

EN-RaychemWinterGardH900-IM-H53665 01/13

2 / 12

Important: For the Pentair Thermal Management warranty to be

valid, you must comply with all the requirements outlined in these

guidelines.

All thermal and design information provided here is based upon a

“standard” installation with heating cable fastened to an insulated

pipe. For any other application or method of installation, consult

Pentair Thermal Management at (800) 545-6258.

HEATING cAbLE SELEcTION AND DESIGN

Make sure that the heating cable being used is suitable for your

application. Refer to the Commercial and Residential Application and

Design Guide (H53585) for heating cable application information.

1. Determine the heating cable type.

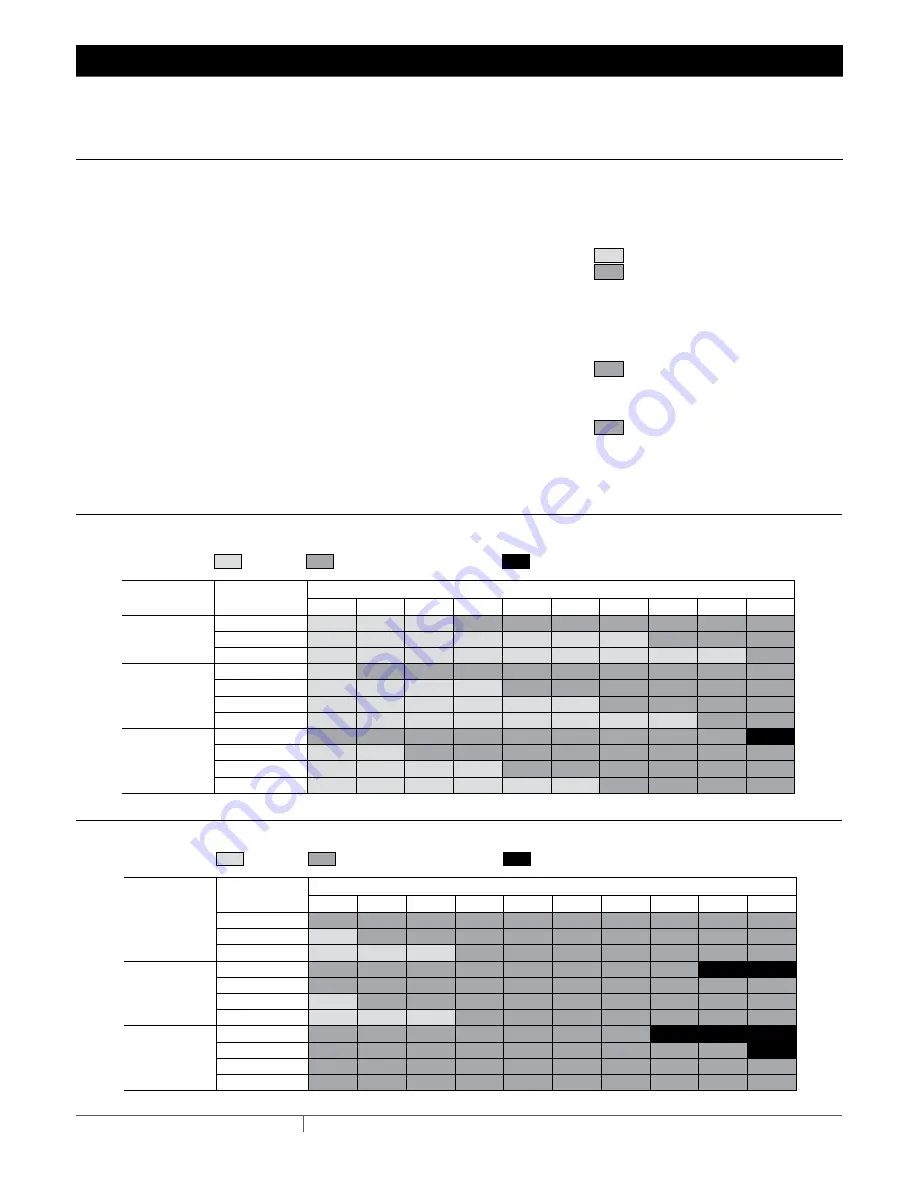

Use Table 1 to select heating cables for insulated metal pipes. Use

Table 2 to select heating cables for insulated plastic pipes. Read

across the table to find your pipe size, then drop down to the line

corresponding to the lowest air temperature for that application and

the correct insulation thickness. The cell at that intersection has a

particular shading and may have a number. The shading indicates

which heating cable to use (key to the shading appears above the table

headings). A number represents the spiraling ratio (feet of heating

cable per foot of pipe).

If no number appears in the cell, straight trace the pipe. If a number

does appear in the cell, spiral trace the pipe.

If your spiraling ratio is 2.0, multiple trace the pipe using two straight

traces at the 4 o’clock and 8 o’clock positions.

If your spiraling ratio is 3.0, multiple trace the pipe using three

straight traces at the 11 o’clock or 1 o’clock position, and at the 4

o’clock and 8 o’clock positions.

Example 1:

Pipe size:

1 in

Lowest air temp.:

0°F

Insulation thickness:

1/2 in

Metal pipe:

WinterGard H311

Plastic pipe:

WinterGard Plus H611, H621

WinterGard Wet H612, H622

Example 2:

Pipe size:

2 1/2 in

Lowest air temp.:

–20°F

Insulation thickness:

1/2 in

Metal pipe:

1.3

WinterGard Plus H611, H621

WinterGard Wet H612, H622

(Use 1.3 feet of heating cable per foot of pipe.)

Plastic pipe:

2.0

WinterGard Plus H611, H621

WinterGard Wet H612, H622

(Use two straight traces at the 4 o’clock and 8 o’clock positions.)

Table 1. For METAL pipes with fiberglass insulation or equivalent (based on 40°F maintain temperature)

Table 2. For pLASTIc pipes with fiberglass insulation or equivalent (based on 40°F maintain temperature)

Lowest air

temp. (°F)

Insulation

thickness

Nominal pipe size

1/2 in

6 in

4 in

3 in

2 1/2 in

2 in

1 1/2 in

1 1/4 in

1 in

3/4 in

1/2 in

1 in

1 1/2 in

1/2 in

1 in

1 1/2 in

2 in

1/2 in

1 in

1 1/2 in

2 in

0

–20

–40

1.8

1.3

3.0

1.8

1.5

1.3

1.1

1.5

1.1

1.1

3.0

2.0

1.7

1.4

1.2

1.1

1.9

1.4

1.1

1.4

1.1

Key to Table 1:

= H311

= H611, H612, H621, H622

= Use a thicker insulation

3.0

2.0

1.7

3.0

1.8

1.5

1.3

1.1

3.0

1.8

1.4

1.7

3.0

3.0

2.0

1.8

1.5

1.1

3.0

1.6

1.4

1.2

3.0

1.8

1.4

1.2

1.6

1.2

1.2

2.0

1.2

1.1

1.3

1.1

1.4

1.1

1.1

1.9

1.7

1.4

1.2

1.1

1.3

1.1

Lowest air

temp. (°F)

Insulation

thickness

Nominal pipe size

1/2 in

6 in

4 in

3 in

2 1/2 in

2 in

1 1/2 in

1 1/4 in

1 in

3/4 in

1/2 in

1 in

1 1/2 in

1/2 in

1 in

1 1/2 in

2 in

1/2 in

1 in

1 1/2 in

2 in

0

–20

–40

Key to Table 2:

= H311

= H611, H612 H621, H622

= Use a thicker insulation

H900 DESIGN AND INSTALLATION INFORMATION FOR HEATING cAbLE ON pIpES ONLy

(WINTERGARD H311, H611, H621, H612, AND H622 HEATING cAbLES).