3 / 12

THERMAL MANAGEMENT SOLUTIONS

EN-RaychemWinterGardH900-IM-H53665 01/13

THERMAL MANAGEMENT SOLUTIONS

3 / 12

2. calculate the total heating cable length required

Length = A + b + c + D + E + F + G + H

A Pipe length x spiraling ratio

b 4 ft x # gate/globe valves x valve length (ft) x spiraling ratio

c 2 ft x # ball/butterfly valves x valve length (ft) x spiraling ratio

D 2 ft x # flanges x pipe diameter (ft) x spiraling ratio

E 2 ft x # pipe supports v pipe diameter (ft) x spiraling ratio

F 1 ft for each power connection

G 2 ft for each splice connection

H 3 ft for each tee connection

= Total heating cable length (ft)

3. Determine the maximum heating cable circuit length allowed.

See Table 3 on the next page. Ensure that your circuits do not

exceed the maximum circuit length listed in Table 3. If necessary,

use additional shorter circuits.

Example (taken from Example 2 [on metal pipe], page 3):

Pipe length:

50 ft

Spiral ratio:

1.3 (from Table 1, page 3)

Globe valves:

3 (each 0.5 ft long)

Pipe supports:

10 supports for 1 in pipe

Power connections:

1

Splice connections:

1

WinterGard heating cable required:

A Pipe length x spiral ratio

= 50 ft x 1.3

= 65.0 ft

b 3 globe valves (0.5 ft each) = 4 ft x 3 x 0.5 x 1.3

= 7.8 ft

c 0 ball/butterfly valves

= 0 =

0

D 0 flanges

= 0 =

0

E 10 pipe supports

= 2 ft x 10 x 0.085* x 1.3 = 2.2 ft

F 1 power connection

= 1 ft x 1

= 1.0 ft

G 1 splice connection

= 2 ft x 1

= 2.0 ft

H 0 tee connection

= 0 =

0

Total heating cable length required

= 78.0 ft

*1 in pipe diameter / 12 in per foot = 0.085 foot

HEATING cAbLE INSTALLATION

1. prepare for installation.

• Store the heating cable in a clean, dry place.

• Complete piping pressure test.

• Review the WinterGard heating cable design and compare to

materials received to verify that the proper WinterGard heating

cable and accessories are available. The WinterGard heating

cable will have the heating cable type printed on the outer jacket.

• Walk the system and plan the routing of the WinterGard

heating cable on the pipe.

2. cut the heating cable to length.

• Cut the heating cable to the length required. This can be done

before or after the cable is attached to the pipe. Leave a minimum

of 1 foot extra heating cable for connection to power. For splice

and tee connections, leave a minimum of 1 foot for each section

of heating cable. WinterGard heating cable can be cut to length

without affecting its heat output per foot.

• Protect the heating cable ends from moisture or mechanical

damage if they will be left exposed before connection.

3. position and attach heating cable to pipe.

• Be sure all piping to be traced is dry.

• Install heating cable, using straight tracing, spiraling, or multiple

tracing according to the “Heating cable selection and design”

section on page 3.

• For straight tracing, install the heating cable on a lower half of the

pipe; for example, in the 4 o’clock or 8 o’clock position.

• Be sure to install the additional heating cable required for valves,

flanges, etc. as indicated in Step 2 of the “Heating cable selection

and design” section.

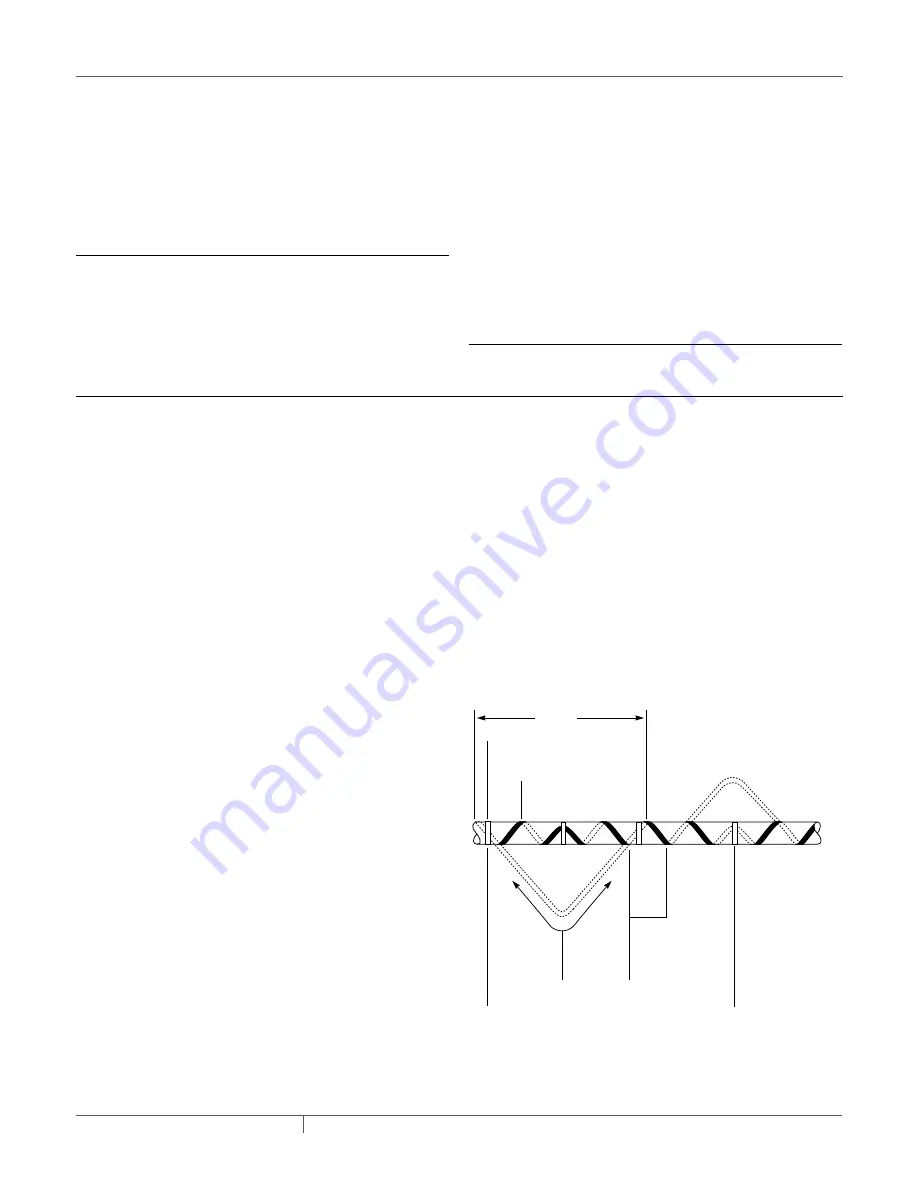

• When the design calls for spiraling, begin by suspending a loop

every 10 feet as shown in Figure 1. To determine the loop length,

obtain the spiral factor from Table 1 or 2 and multiply by 10. For

example, if a spiral factor of 1.3 is called for, leave a 13-foot loop

of heating cable at every 10-foot section of pipe. Grasp the loop

in its center and wrap it around the pipe. Even out the distance

between spirals by sliding the wraps along the pipe. Use glass

tape to secure the center of the loop to the pipe. Secure the

heating cable flat to the pipe to obtain good contact.

• Tape WinterGard heating cable to the pipe at 2-foot intervals using

Raychem H903 fiberglass application tape or nylon cable ties. Do

not use vinyl electrical tape, duct tape, metal bands, or wire.

4. Install heating cable end seals, splices, tees, and power

connection.

• Install all end seals, splices, tees, and power connection prior to

plugging in.

• If splicing or teeing, use only the H910 WinterGard Splice and Tee

Kit to satisfy code and agency requirements.

• H900 kit assembly instructions begin on page 9.

5. check the installation.

• Prior to installing thermal insulation, make sure the heating

cable is free of mechanical damage (from cuts, clamps, etc.) and

thermal damage (from solder, overheating, etc.).

• Visually check all power connections, end seals, splices, and tees.

• Using a megohmmeter, test each circuit according to the

instructions in the “Heating cable testing and maintenance”

section (page 5) both before and after installing the thermal

insulation.

Figure 1. Spiraled heat tracing

10 feet

Glass tape

(typical)

Heating

cable

Tape after

spiraling

heating

cable on

pipe

Wrap loops

in opposite

direction

Pull heating

cable loop

length

Apply glass

tape before

spiraling

heating cable

on pipe