Installing New Seal

1. NOTICE: Seal faces are highly polished and lapped.

Handle with care. Any mar, nick or scratch on seal

face will cause it to leak. BE SURE to install with

polished faces toward each other.

2. Clean polished surface of ceramic seat with

clean cloth.

3. Wet O-Ring around ceramic seat with liquid soap.

4. Press stationary (ceramic) half of seal into cavity

firmly and squarely with thumb pressure. If it does

not seal properly, remove and place face up on

bench. Re-clean adapter/seal plate cavity. Seal

should now seat correctly.

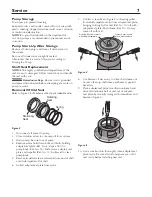

5. If seal does not seat after recleaning adapter/seal

plate cavity, place a cardboard washer over polished

face of seal and carefully press into place using a

piece of 1” standard pipe as a press. (Figure 6).

NOTICE: BE SURE you do not scratch seal face.

6. Dispose of cardboard washer and recheck seal face

to be sure it is free of dirt, foreign particles, scratches

and grease.

7. Inspect shaft and shaft sleeve to be sure they

are clean.

8. Re-install O-Ring, shaft sleeve and slinger (Ref. No.

4) on shaft.

NOTICE: A small amount of grease or Never-Seez

under shaft sleeve will help prevent shaft and sleeve

from freezing together when pump is in service.

9. Remount adapter/seal plate to motor, being careful

not to scratch seal face.

10. Apply liquid soap to inside diameter and outside

face of rubber drive ring on rotating half of seal.

11. Slide seal assembly onto shaft sleeve (sealing face

first) far enough so that seal spring is located on shaft

sleeve. NOTICE: Be careful not to nick carbon seal

face when passing it over end of shaft sleeve.

12. Slide impeller and gaskets (Ref. Nos. 12 and 11) onto

shaft with key (Ref. No. 3) in position. Be sure to

maintain proper order as shown in Repair Parts.

13. Install washer, gaskets, and impeller screw (Ref. Nos.

14, 15, 16, 17) on end of shaft and tighten screw

until it is snug. This should locate seal in place and

bring seal faces together.

14. Re-install motor, adapter and impeller assembly on

volute, using new gasket (Ref. No. 7).

15. Re-install motor hold- down bolts.

16. Check all bolts for tightness.

17. Pumps below water level: Close drains; open

isolation valves to fill pump. Pumps above water

level: Prime pump. Open isolation valves if they

were closed at disassembly.

18. When pump is full, close air vents.

19. Reconnect power to pump and system is ready

for operation.

1" Standard Pipe

Stationary Seat

Cardboard

Washer

(Supplied with seal)

1422 1294

Figure 6

Service 8

Summary of Contents for S40093

Page 11: ...This page intentionally left blank...

Page 12: ......