Smart pH

10

Smart pH

Water Chemistry Controller

INT

ELLIGENC

E

IN

S

ID

E

ACU-TROL

I

N

S

ID

E

www.acu-trol.com Made in USA 110 VAC, 5A

Disconnect power source before servicing unit

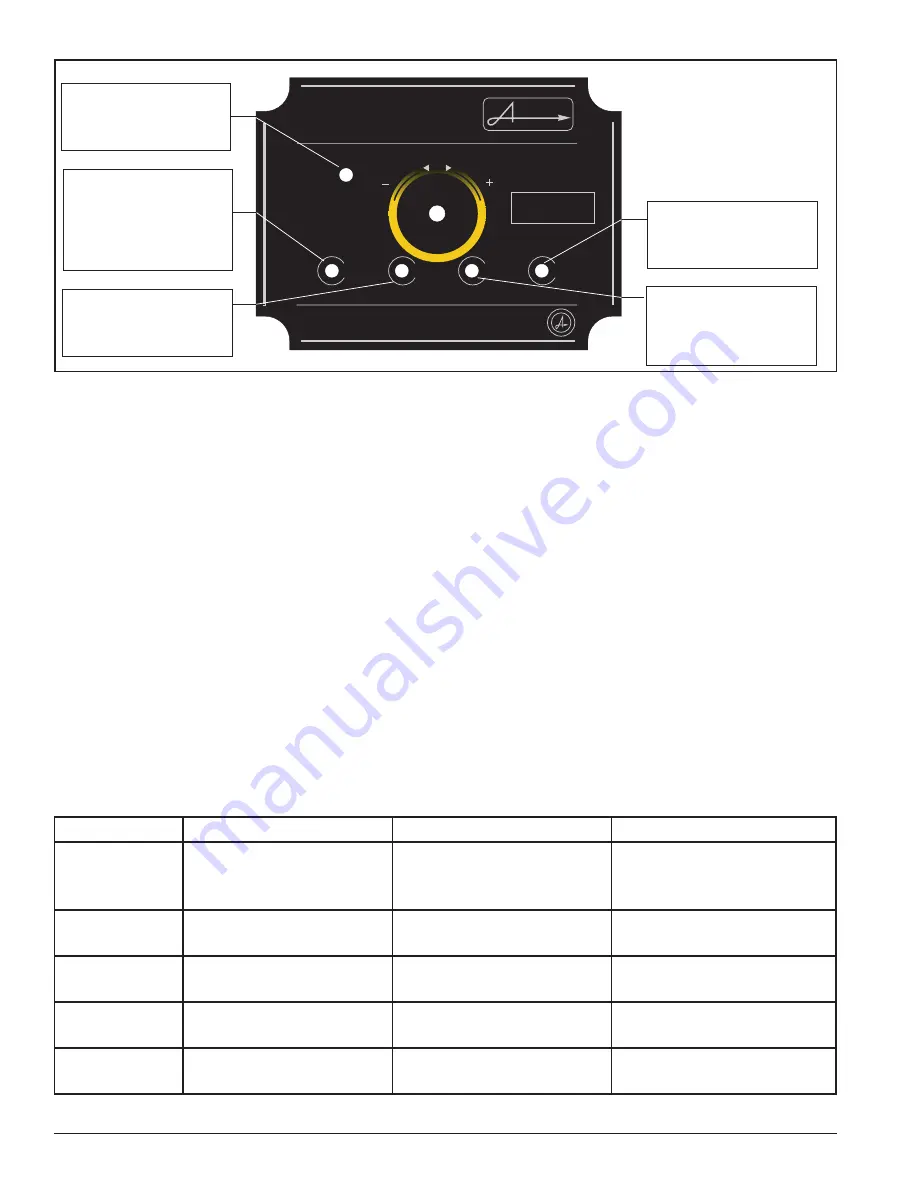

Turn “Set Point” knob to the

far left or right to trigger pH

reading function

(see manual for details)

POWER

HIGH

BALANCED

LOW

CHEMICAL

FEED

pH

pH

pH

Set Point

cu-Trol

PROGRAMMABLE CONTROLLERS

®

Figure 6. Smart pH Basic Operation

POWER Indicator

Indicates when power is

provided to the unit

CHEMICAL FEED

Indicator

lights green, indicating

that chemicals are

flowing

LOW Indicator

lights red, indicating

pH

is low

HIGH Indicator

lights red, indicating

system pH is high

BALANCED Indicator

lights green, indicating

set point has been

reached

STARTUP

SETTING pH

Measure the pH using a standard test kit. If not already done, close up the front cover of the Smart pH. When the

knob (potentiometer) is turned all the way to the right or left the units Low, Balanced, and High LED’s will begin to

flash simultaneously. Count the number of flashes on each LED. This will be the reading of the pH probe being moni-

tored. For example, for a pH reading of 6.23 the Low LED will flash 6 times, the Neutral LED will flash 2 times and

the High LED will flash 3 times. The LED’s will all go off for approximately 2 seconds and then restart again until the

knob is moved back into the set point range. Chemical feeding will stop when the Smart pH detects there is no flow.

See Chapter 6, "Setup Check Out Sheets" for help with start up.

The Smart pH is not an absolute measuring de-

vice. If the pH of the system is too high turn the knob to the left and monitor over some period of time. If the pH is too

low turn the knob to the right and then monitor over time. Monitor the ph readings by using the hand check method

and adjust the Smart pH to achieve the desired reading. Normally the probes should read +/- .5 of the hand check, if

out of this range the probe may need to be cleaned (See "Cleaning Probe", Section 4.2).

TROUBLESHOOTING

PART

PROBLEM

SOLUTION #1

SOLUTION #2

pH Levels

High pH won't come down

even after turning control

down

Check chemical tank and

make sure it is not empty

Check power connection

between the Smart pH and

the chemical controller

pH Sensor

Reading never matching

hand check

Clean sensor, check ground

on input power

Check total alkalinity

pH Sensor

Readings never matching

hand check

Short (+) (-) on sensor,

pH = 7.0. Remove sensor

Sensor may need to be

cleaned

Flow Switch

Not working

Check continuity when flow

is present

LED's Flashing Overfeed alarm ON

1 hour or none only

Make sure feeder is working

properly

Summary of Contents for Smart pH

Page 2: ......