Maintenance 7

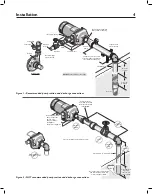

In stallation of Rotating Part of Seal

Unit

(Figure 5D)

1. Reinstall seal plate using extreme caution not to hit

ceramic portion of seal on motor shaft.

2. Inspect shaft to make sure that it is clean.

3. Clean face of sealing washer with clean cloth.

4. Lubricate inside diameter and outer face of rubber

drive ring with soapy water and slide assembly on

motor shaft (sealing face first) until rubber drive ring

hits shaft shoulder.

5. Screw impeller on shaft until impeller hub hits shaft

shoulder. This will automatically locate seal in place

and move the sealing washer face up against seat

facing. Reinstall impeller screw (if used).

5939 0412

Figure 5

A - Seal removal - rotating half

Mechanical seal

stationary half

Polished surface

Shaft shoulder

D - Seal installation - rotating half

Seal plate

3/4” socket or pipe

Rubber

drive ring

C - Seal installation - stationary half

Turn over

Cardboard washer

(supplied with seal)

Sealing

face

Mechanical seal

rotating half

Rubber surface

Impeller

B - Seal removal - stationary half

Risk of electric shock. Can shock, burn or kill. To guard against accidental personal injury, the electric

power to the pump should be turned off when conducting the checking procedures outlined. There are obvious

exceptions, however, and service personnel should take necessary safeguards against the hazard of electrical shock.

Problem

Probable Cause(s)

Remedy

Pump fails to pump.

Pump not properly primed.

Make sure pump casing and suction line are

full of water. See priming instructions.

Pump has reduced

capacity and/or head.

Air pockets or leaks in suction line.

Check suction piping.

Clogged impeller.

Remove and clean.

Pump loses prime.

Air leaks in suction line.

Check suction piping.

Excessive suction lift and operating too near

shut-off point.

Move pump nearer to water level.

Water level drops while pumping,

uncovering suction piping.

Check water supply. Add length of pipe to

suction to keep submerged end under water.

Mechanical troubles

and noise.

Bent shaft and/or damaged bearings.

Take motor to authorized motor repair shop.

Suction and/or discharge piping not properly

supported and anchored.

See that all piping is supported to relieve

strain on pump assembly.

Troubleshooting