EN-TraceTekTT1100OHP-IM-H58263 01/15

THERMAL BUILDING &

INDUSTRIAL HEAT TRACING SOLUTIONS

3 / 8

Maximum

offset = 1/4 in

End termination

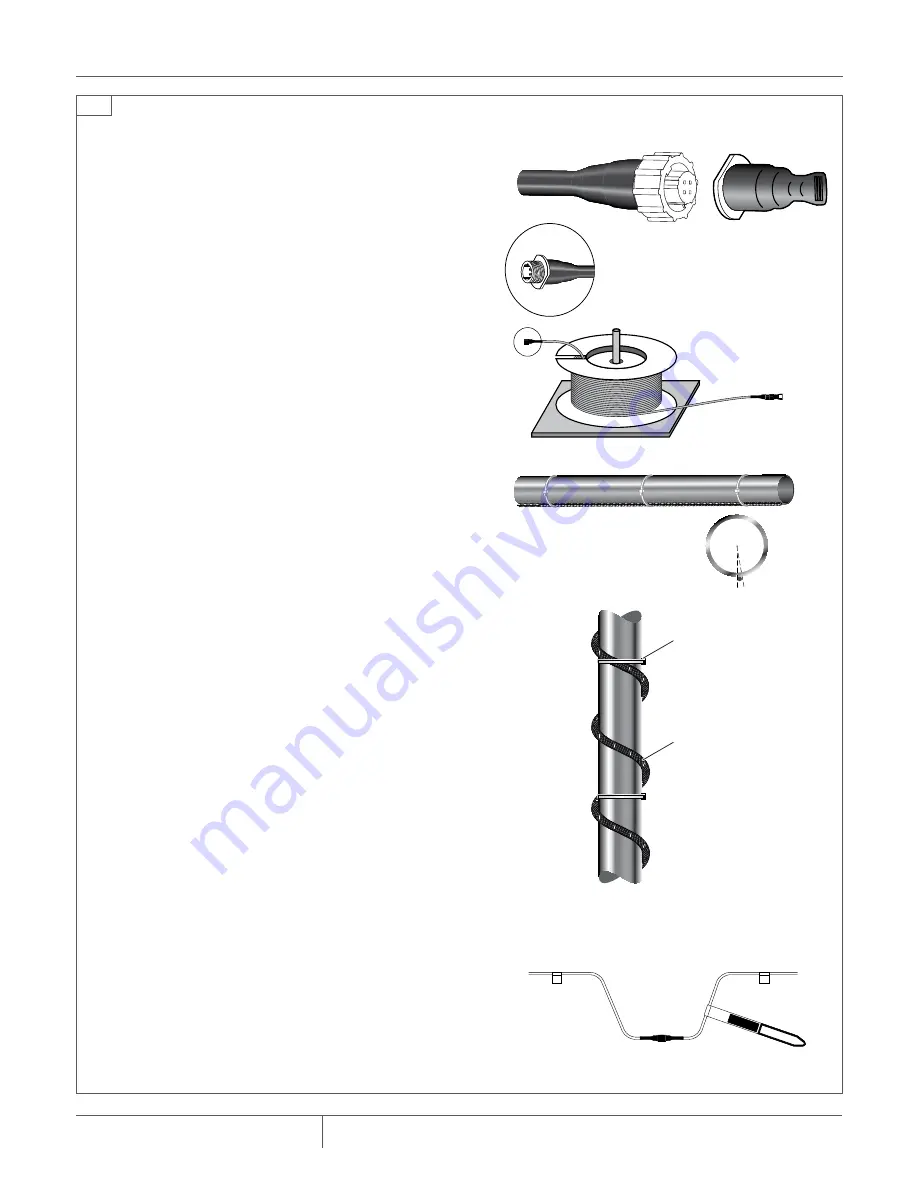

Cable connector with pins

toward alarm module

Tie-wrap

Sensor

cable

TraceTek

Systems

Service

loop

4

connect, orient, install, and test each length of sensing cable in

sequence

1.

connect

a Modular End Termination (TT-MET-PC) to the first sensing-cable

length to be installed.

2.

orient

sensing cable so the connector used with the end termination will

be the furthest away from connection to the TraceTek alarm module. Work

out from the alarm module connection. For sensing cable on reels (lengths

over 10 feet (3 m)), put the reel on an axle and pull the cable out.

3.

install

sensing cable in accordance with the leak detection layout plan.

A. For pipeline applications:

• Position the cable along the bottom of the pipe and use tie wraps to

secure the cable at the 6 o’clock position. Maintain cable position

within 1/4 inch (6 mm) of 6 o'clock position.

• Tie wraps should be long enough to go around the pipe and the sen-

sor cable.

• Use one tie wrap every 12 in to 18 in (300 to 450 mm) along the pipe

with extra tie wraps at fittings or bends as needed.

important

: It is the installer’s responsibility to position the sensor cable

correctly. The cable must trace the lowest point of the pipe or fittings

such that any water leaking from the pipe or fittings will drip onto the

cable surface as it drips off the bottom of the pipe or fitting. Do not

install the cable on the top or side surface of a pipe. Do not spiral the

cable on horizontal pipe.

exception

: If the cable is used to trace vertical pipe, the cable should be

spiraled around the pipe and secured with tie-wraps.

B. For sumps, containment trenches, and subfloor applications:

• Pull the cable alongside the installed hold-down clips; minimum bend

radius is 2 in (50 mm). Leave 6 in (150 mm) of sensing cable on each end

for the connector service loop.

important

: Verify that the adhesive securing the hold-down clips has

dried; liquid adhesive must not contact the cable.

Push sensing cable into the hold-down clips and position the sensing

cable to lay flat on the surface to be monitored. Secure by snapping

hold-down clip end into base.

4.

test

each length of sensing cable after installing it and before attaching

it to cable already installed. Confirm that the sensing cable is clean and

intact by following the Sensing Cable Test Procedure.

5.

connect

the sensing cable to the cable string (lengths of sensing cable

connected in series) previously installed.

For sumps, containment trenches, and subfloor applications:

• Leave a service loop at each connector as shown.

• Mark the connector position on the layout plan.

• Install TraceTek mapping tag (TT-TAG).

•

note

: As an extra precaution on large installations, periodically test the

entire cable string to confirm that all installed sensing cable is still clean

and intact.

• Unplug the end termination and connect it to the next length of sensing

cable to be installed.

6.

repeat

the installation sequence for each length of cable.