EN-TraceTekTT1100OHP-IM-H58263 01/15

THERMAL BUILDING &

INDUSTRIAL HEAT TRACING SOLUTIONS

4 / 8

TTC-1, TTSIM-1, TTSIM-1A,

TTSIM-2 or TTDM-128

TT-MET-PC TT1100-OHP TT-MLC-PC

Modular

leader cable

Modular end

termination

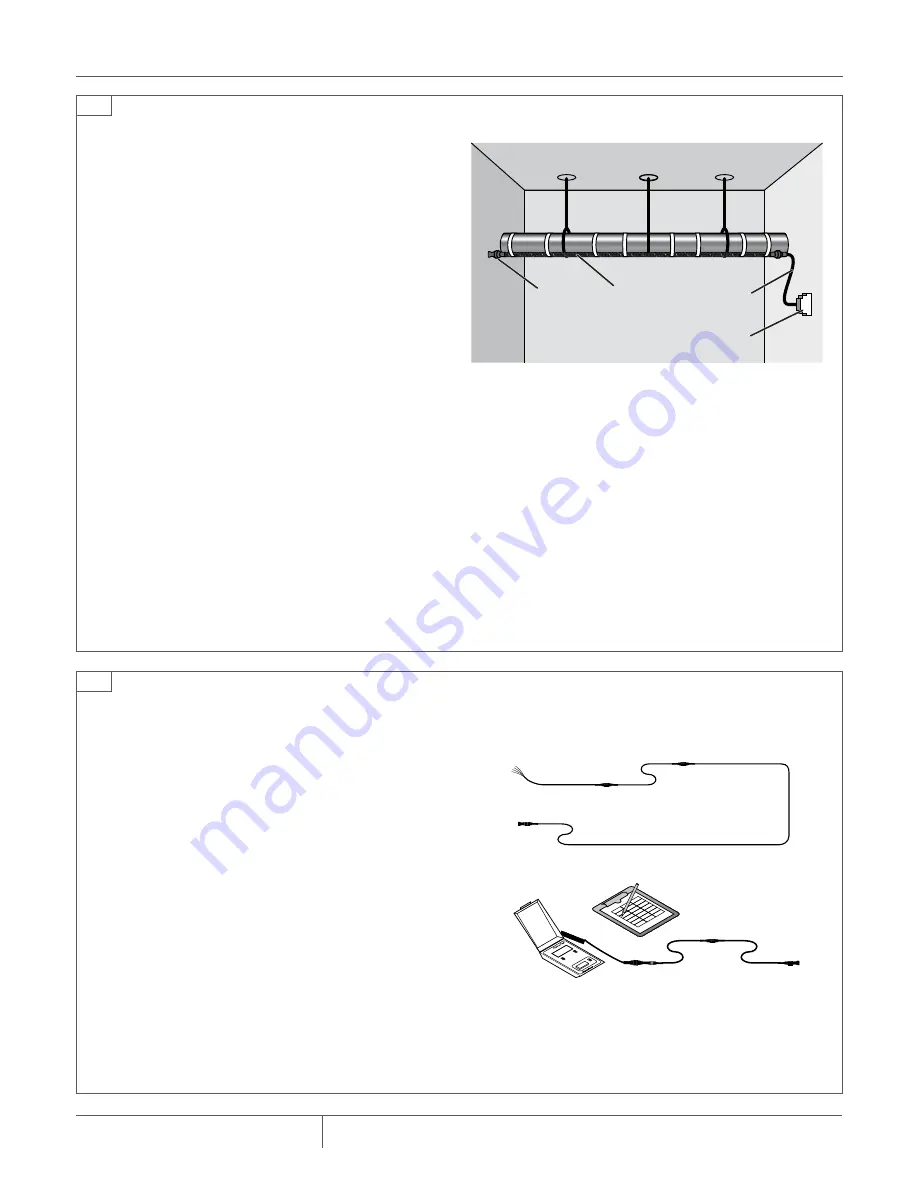

5

6

complete the system

1. Install other TraceTek components (such as Modular

Branching Connectors, Weighted Lengths, and Modular

Jumper Cables) as called for in the system layout. Complete

the sensing circuit.

note

: All components of the system have male or female metal

connectors or both. The male connectors are oriented toward

the instrument panel. As new sections of cable are added to

the main leg or branch, each newly added section should end

with an open female connector. The end of each branch or

main leg is terminated with a male end termination.

2. Test the sensing circuit (or portions of it) to confirm that the

sensing cable is clean and intact. Follow the Sensing Cable

Test Procedure.

3. Connect the sensing circuit to the TraceTek alarm module

and activate the system as soon as is practical. Use the

alarm module to monitor the sensing cable during the final

stages of construction.

take precautions if installation is incomplete at end of

work day.

At the end of the work day:

• Ensure that there are no open connectors. Each sensing

cable should be connected to a Modular Leader Cable (TT-

MLC-PC), Modular End Termination (TT-MET-PC), and/or

other sensing cables; check both ends of the cable.

• Test and record the condition of installed sensing cable fol-

lowing the Sensing Cable Test Procedure.

• If practical, connect the installed sensing cable to the

TraceTek alarm module. Test the system and put it in opera-

tion following the alarm module installation instructions.

At the beginning of the next work day:

• Check that the installed sensing cable is clean and intact

following the Sensing Cable Test Procedure. Compare the

results with those obtained at the end of the previous work

day. If necessary, investigate and correct problems before

proceeding.