SMART I/O User’s Manual

March 12, 1996

©1996 PEP Modular Computers GmbH

Page 5 - 32

Chapter 5 Analog Modules

The two- and three-wire measurement methods shown in figure 5.2.5.2 are

not compensated and will experience errors due to line-resistances. The best

and recommended method is the 4-wire system shown in figure 5.2.5.1.

which eliminates all line resistances automatically. The sense lines, being

connected to a high impedance differential amplifier (10M

Ω

), introduce

almost zero error resulting from line-resistances.

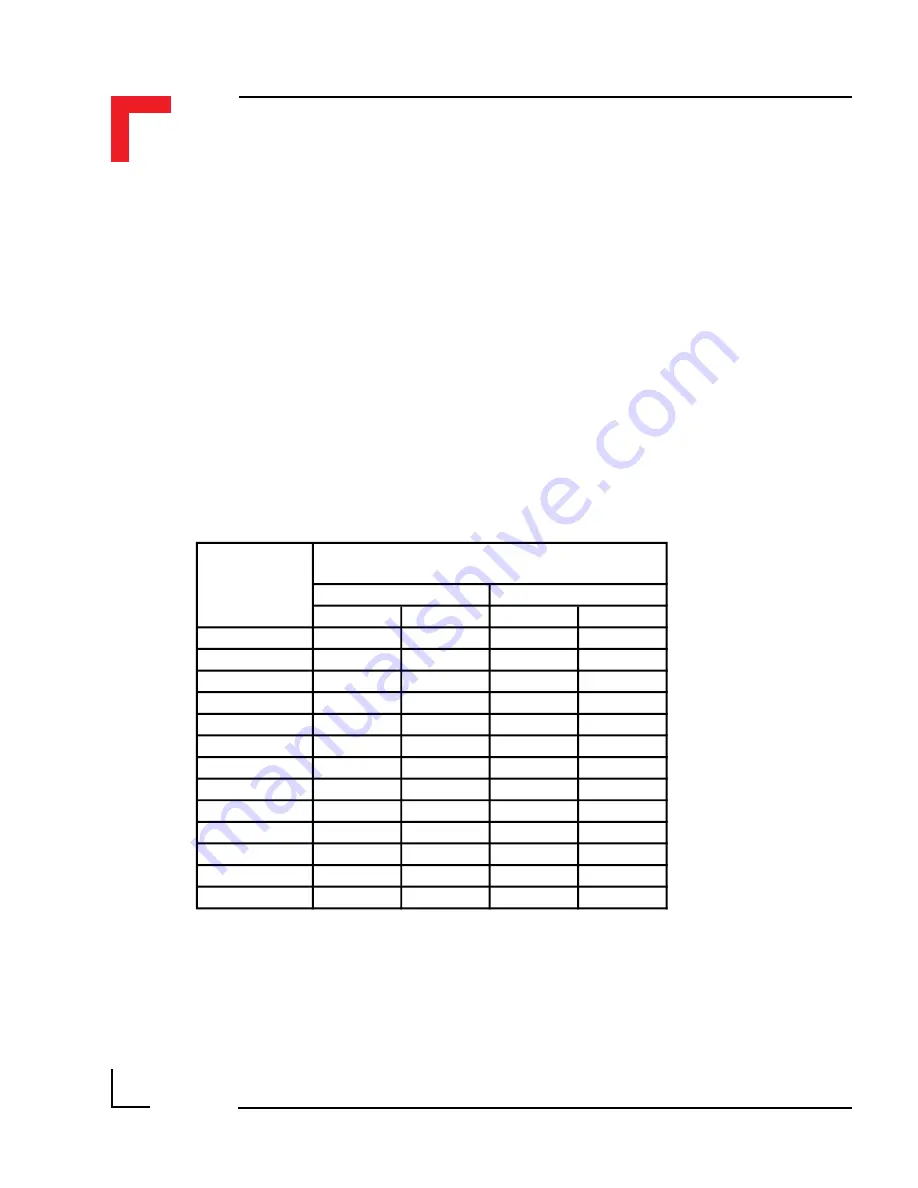

Table 5.2.5.2 shows the deviation from the required temperature for both

class A and class B PT100 sensors.

Table 5.2.5.2 Tolerances between Class A and Class B Sensors

Temperature

°

C

Tolerance

Class A

Class B

°

C

Ω

°

C

Ω

-200

±

0.55

±

0.24

±

1.3

±

0.56

-100

±

0.35

±

0.14

±

0.8

±

0.32

0

±

0.15

±

0.06

±

0.3

±

0.12

100

±

0.35

±

0.13

±

0.8

±

0.30

200

±

0.55

±

0.20

±

1.3

±

0.48

300

±

0.75

±

0.27

±

1.8

±

0.64

400

±

0.95

±

0.33

±

2.3

±

0.79

500

±

1.15

±

0.38

±

2.8

±

0.93

600

±

1.35

±

0.43

±

3.3

±

1.06

650

±

1.45

±

0.46

±

3.6

±

1.13

700

–

–

±

3.8

±

1.17

800

–

–

±

4.3

±

1.28

850

–

–

±

4.6

±

1.34

Driver software running under OS-9 supplies linearization data for use with

DIN standard PT100 sensors. The on-board EEPROM contains board

specific calibration data for self calibration purposes.