2

7

1

6

9

5

2

0

1

7

-1

2

42

SLCT* and SLCT*/35 safety light curtains

Appendix

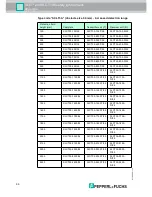

Type code "SCLT14-* (obstacle size 14 mm)

Obstacle size

Protection field

height

Device type

Building

regulation

Detection

range

XX [mm]

YYYY [mm]

Z

AAAA

14

100, 200, 300,

1200

T, R

No

specification

Standard

30

100, 200, 300,

2400

T, R

No

specification

Standard

Increased

detection

range "/35"

60

300, 600, 900,

2400

T, R

No

specification

Standard

Increased

detection

range "/35"

90

300, 600, 900,

2400

T, R

No

specification

Standard

Increased

detection

range "/35"

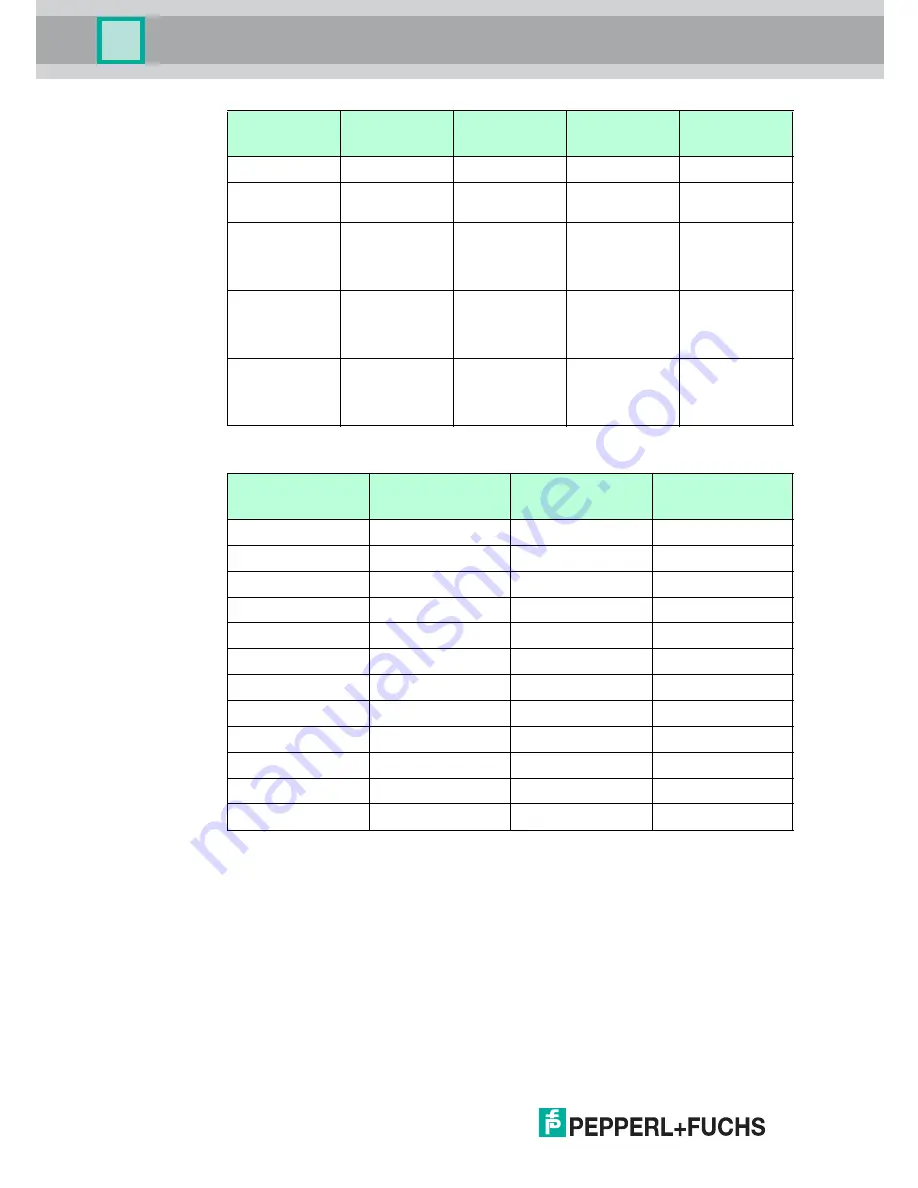

Protection field

height [mm]

Complete

Transmitter unit (-T)

Receiver unit (-R)

100

SLCt14-100

SLCT14-100-T

SLCT14-100-R

200

SLCT14-200

SLCT14-200-T

SLCT14-200-R

300

SLCT14-300

SLCT14-300-T

SLCT14-300-R

400

SLCT14-400

SLCT14-400-T

SLCT14-400-R

500

SLCT14-500

SLCT14-500-T

SLCT14-500-R

600

SLCT14-600

SLCT14-600-T

SLCT14-600-R

700

SLCT14-700

SLCT14-700-T

SLCT14-700-R

800

SLCT14-800

SLCT14-800-T

SLCT14-800-R

900

SLCT14-900

SLCT14-900-T

SLCT14-900-R

1000

SLCT14-1000

SLCT14-1000-T

SLCT14-1000-R

1100

SLCT14-1100

SLCT14-1100-T

SLCT14-1100-R

1200

SLCT14-1200

SLCT14-1200-T

SLCT14-1200-R