iQntrol DOS-MODBUS

Original manual in German Version 1.0.2 2022.10.06

26/39

8.2.2

Main menu

Service

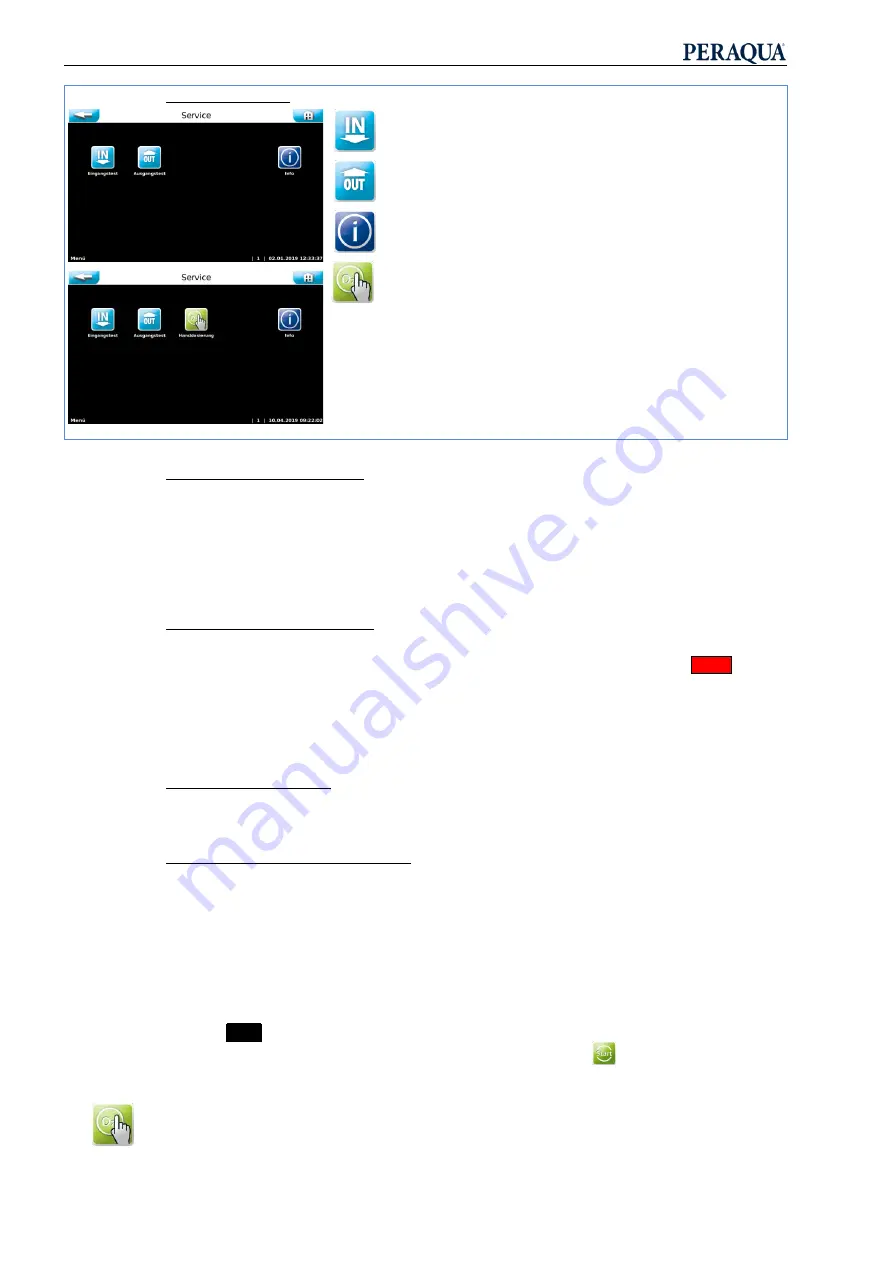

The picture below shows the time control variant

Input test

a test programme for switch inputs

Output test

a test programme for pumps and relay outputs

Info

for the query of firmware versions

Manual dosing O

2

For carrying out a manual disinfectant dosing

The desired disinfectant volume must be set

For commissioning or if additional disinfectant is required

The default value is 3,000 ml

8.2.2.1

Main menu

Service

Input test

The input test serves for checking the connected inputs (switches). The changing activation of the switches is indicated by 0

(open) or 1 (closed).

The switch function has a wire-break proof design (pH regulation level, disinfection level, measuring cell flow, central control

technology off and clean water external). I.e., these functions are closed in the operating state; in the event of a disruption (e.g.,

container empty, or wire break) the input opens, resulting in an error message.

8.2.2.2

Main menu

Service

Output test

The output test is used for checking the connected outputs (pumps and relays). The selected output is activated for 30 seconds.

The activation time can be selected between 5 and 120 seconds. The activation can be cancelled at any time with

–

Stop

–

.

For safety reasons (generation of chlorine gas), the output test only functions if it has been ensured that the dosed chemicals are

being removed.

Therefore, no disruption, e.g., “Measuring cell flow”, may be pending!

8.2.2.3

Main menu

Service

Info

Info allows you to query the currently used versions of the two firmware`s, DSP and IO.

8.2.2.4

Main menu

Service

Manual dosing O2

There are situations when manual dosing may be required. For example, if the disinfection container was not replaced in due time

and the next regular disinfection would only take place several days later. The operator notices an insufficient disinfection effect

(slick basin walls). Or during commissioning, if the regular dosing will not take place until some time far in the future. In this case,

the Service menu provides the possibility to initiate a manual dosing. Upon completion of the manual dosing, the controller

automatically returns to the normal control operation.

Proceeding:

-

Select the Manual dosing menu

-

Enter the desired or required dosing volume

-

Acknowledge with -

Start

-

-

Upon completion of the dosing delay, the manual dosing starts (may be skipped with

)

-

Upon completion of the manual dosing, the device automatically returns to the normal automatic operation

-

The manual dosing may be terminated at any time with the MENU button

The

icon is displayed below the remaining dosing volume to signal an active manual dosing.