Assembly and Operation Manual

2.2. Set the

Waiting period for verification confirmation.

Within that time the

controller will wait for the

“Card captured”

signal.

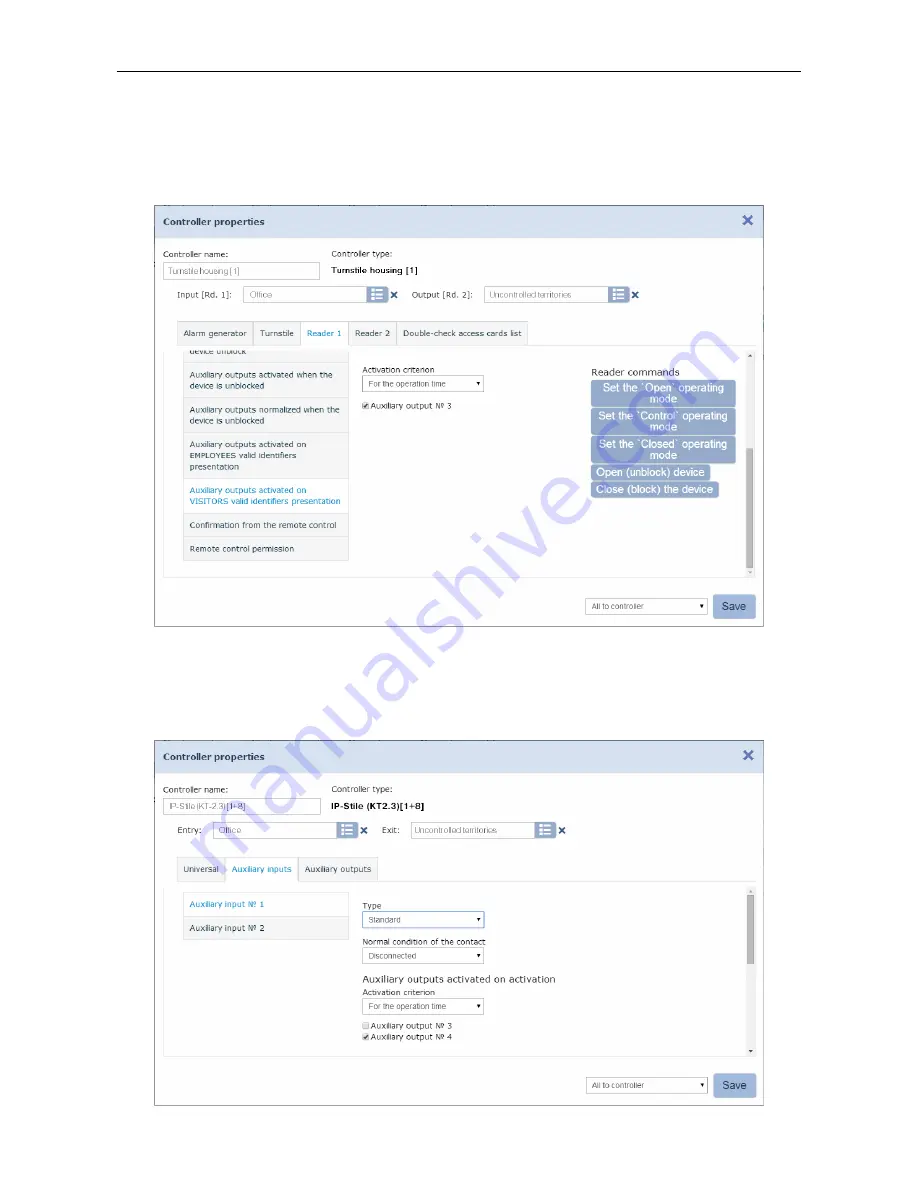

2.3. For parameter

Auxiliary outputs activated on VISITORS valid identifiers

presentation

set the

Activation criterion

as

For the operation time

. After that

mark by flag

Auxiliary output

№

3.

Activation of this output will be a signal for

“Card capture”

to the card capture reader:

3. The card capture reader generates the

“Fault”

signal to the auxiliary input

№

1 and

“Activation of auxiliary input”

is registered at that. The system response can be

configured. For controller

Auxiliary input

№

1,

parameter

Type

set as

Standard.

Parameter

Normal condition of the contact

set as

Disconnected.

Using the other

parameters configure the system response:

16