WARRANTY CARD

WARRANTY REPAIR COUPON

Cutting line

Cutting line

1

.

APPLICATION

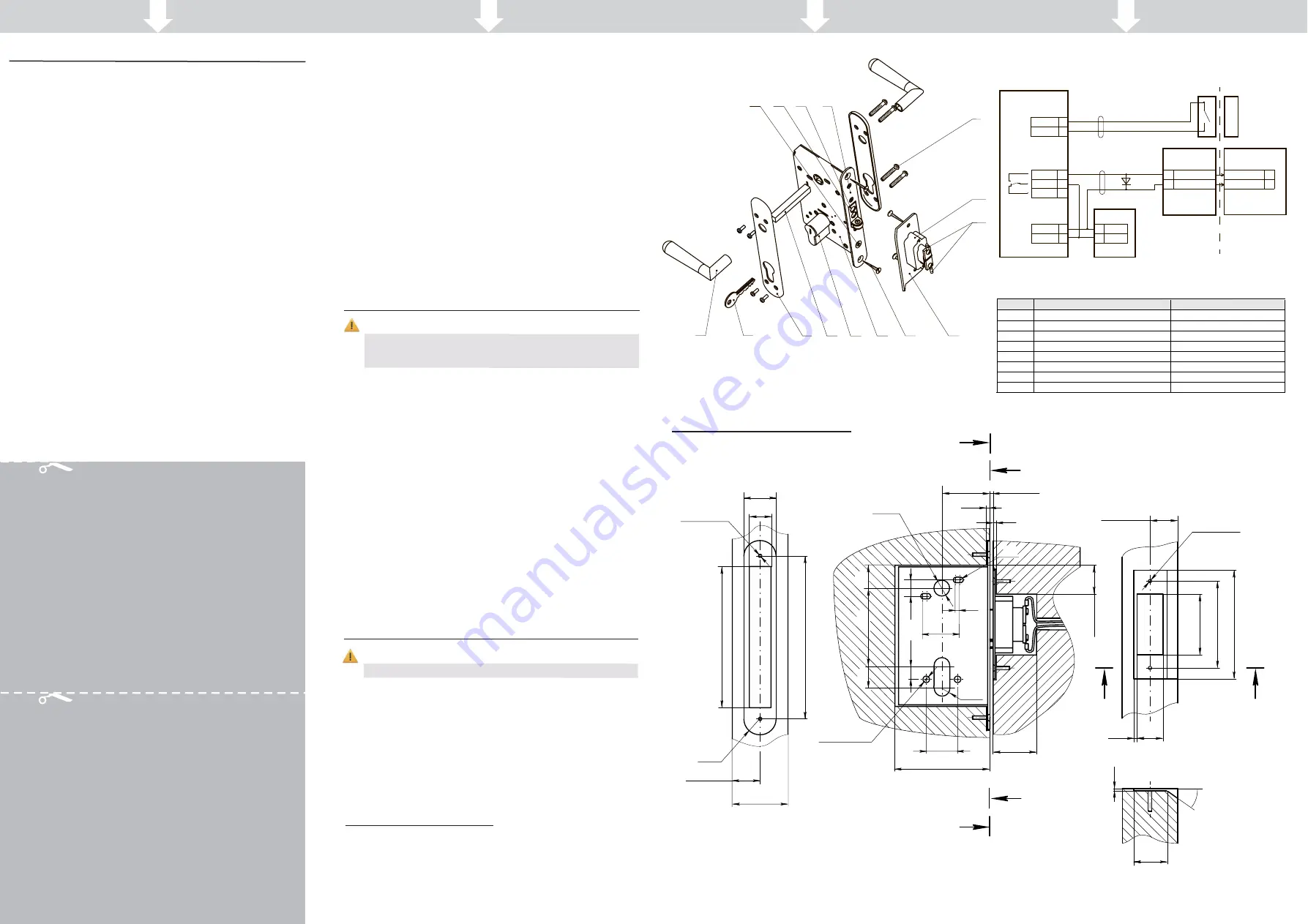

Fig. 1. LB-72.1 electromechanical lock design

- Not included in the delivery set

*

1

2

3

4

3. STANDARD DELIVERY SET

Fig. 3. LB-72.1 electromechanical lock layout

LB-72.1

is a normally-closed electromechanical mortise door lock (hereinafter

– the lock), designed to be used as an operating device as a part of access

control system (hereinafter – ACS) to control light and medium office doors.

Lock features:

•

the lock has a unique construction, allowing to connect lock control cable

through the strike plate in the door frame, not through the door leaf, which

makes installation easier;

•

the lock can be installed in wooden and non-metallic doors 38-50 mm thick;

•

a universal lock construction enables its installation on both right-handed

and left-handed doors;

• the lock is designed for use with standard lock cylinders;

•

all components of the lock and strike plate have corrosion-resistant coating;

• the lock is resistant to self-opening (for instance, as a

result of a hard kick

on the door);

• the lock has low power consumption (max 2 W

);

•

the design of the lock does not require preventive maintenance and

lubrication from the customer for the entire period of operation;

• the lock closes automatically at shutting the door;

• the lock can be released with th

e key or by a signal from ACS;

• de-energized lock can be rel

eased with the key only.

The lock with regard to resistance to environmental

exposure

complies with

GOST 15150-69, category NF4 (operation in premises with climate control).

Operation of the lock is allowed at ambient air temperature from +1°C to

+40°C and at relative air humidity of 75% at +15°C.

The lock has a marking in the form of label located on its housing. The label

contains product name, its serial number, the manufacture date and its main

technical specifications.

The product is packed in a carton

box,

protecting it from being damaged

during transportation and storage.

Box dimensions (

L

× W × H) ...................................................... 12×22×4 cm

Gross weight ...............................................................................

max. 0.7 kg

Lock storage is allowed indoors at ambient air temperature from

-50°С

to

+50°С. Storage time in closed package is 12 months.

The lock in the original package can be delivered by means of land (railway

and road), sea and air transport. It is allowed to stack the

boxes

while in

transit.

2. TECHNICAL SPECIFICATIONS

Attention!

Due to the continual product improvement the manufacturer

reserves the right to introduce amendments in product design

without previous notice.

Technical parameters of the lock comply with GOST 538-

2

001 and

GOST

5089-20

11.

DC voltage ..................................................................................... 11 – 13 V

Operational

current ................................................................... 0.08 - 0.12

A

Power consumptio

n ........................................................................ max. 2W

Type (fail-safe performance) ................................................ normally-closed

Bolt throw, not less than ..................................................................... 15 mm

Centre-to-centre spacing .................................................................... 72 mm

Dimensions .......................................................................... 85×22×172 mm

W

eight .......................................................................... not more than 0.5 kg

Lock type .......................................................................................... cylinder

Unauthorized access protection (UAP) .......... normal, GOS

T

R 51241-2008

Resistance to opening .......................................... І as per GOST 5089-20

11

Safety requirements .................................................. GOST R IEC 335-1-94

Electric shock protection class ...................III as per GOST R IEC 335-1-94

MTBF ............................................................. 200000 number of operations

Average lifetime ................................................................................ 8 years

Design and composition of the lock are shown in Fig. 1.

Attention!

Check the delivery set upon product receipt.

1

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

.

k

c

o

L

1

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

.

e

t

a

l

p

e

k

ir

t

S

1

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

k

c

o

l

b

l

a

n

i

m

r

e

T

2

1

1

2

4

5

6

7

8

9

3

11

12

13

14

10

15

1. Lever ; 2. Key; 3. Escutcheon plate fastening screw; 4. Escutcheon plate ;

5. Lever rod ; 6. Lock cylinder ; 7. Lock; 8. Screw 3.9×25;

9. Strike plate; 10. Terminal block; 11. Terminal clamps;

12. Locking m

echanism roller; 13. Locking bolt; 14. Forend plate;

15. Lock cylinder fastening screw M5×50

*

*

*

*

Position

Unit

Note

1

Control cable of the ACS controller

2

Reed switch cable

A1

Power supply unit

12V; 0,5А; 6 W

A

2

Lock controller

A3

Terminal block

А

4

Lock

S1

Reed switch

A2

Input

NO

C

NC

+12V

VD1

Terminal

block

Lock

magnet

S1

A1

A3

A4

Contact 1

Contact 2

1

2

Contact 1

Contact 2

1

2

ACS controller

IN

GND

Output

+U

GND

+12V

+U

GND

The universal construction provides use of standard pin-type lock cylinders, standard

EuroDIN (V DIN 18

2

54), e.g. type 8809, 8

2

09, 8

2

59 produced by company ISEO

(Italy), or lock cylinders of D series by Wilco Supply (ty

p

e 254 – 274 – 294, 453, 454,

554).

The length of lock cylinder fastening screw should not exceed 50 mm.

The lock cylinder with a set of keys, door levers with fi

x

ing elements, reed switch,

control and reed switch cables are not included in the delivery set.

2

1

Fig. 2. LB-72.1 electromechanical lock installation layout

A

A

B

B

B-B

A-A

C

C

C-C

Ø3,5×30

3

24

56

80

100

2

35°

31

L / 2

±0,5

L / 2

±0,5

26,5

±1

2,5±1,5

44

2

2

R3

34

4

21

51

R10

27

87

40

21

72

16

2 holes

Ø7

Ø20

2

holes

Ø3,5×30

130

22

16

150

R11

L=38...50

L - Thickness of door leaf

2 holes

)

A

C

6

1

E

K

6

P

,

B

5

1

-

6

0

W

Z

B

(

V

8

1

–

5

1

Suppressor

1

D

V

Screw 2.9×13 DIN7982 .........................

.

....................................................... 2

Screw 3.9×25 DIN7982 ..................

4

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

1

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

.

e

t

a

l

p

m

e

t

n

o

it

a

ll

a

t

s

n

I

1

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

l

a

u

n

a

m

n

o

it

a

r

e

p

o

d

n

a

e

t

a

c

if

it

r

e

C

Package box .................................................................................................

1

1

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

.

.0

5

×

5

M

w

e

r

c

s

g

n

i

n

e

t

s

a

f

r

e

d

n

il

y

c

k

c

o

L