ST-02 Speed gate and STD-02 Double-sided section

9

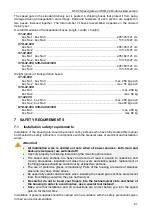

Figure 4. STD-02 overall view

1 – sliding panel; 2 – filling glass; 3 – glass cover; 4 – central insert;

5 – upper indication block; 6 – side panel; 7 – front panel; 8 – front end indication block;

9 – DC connection cable

; 10 – CAN

1

connection cable; 11 – RC-panel with cable;

12 – power supply cable

; 13 –

Fire Alarm

2

device cable;

14 – lower level of passage sensors; 15 – upper level of passage sensors

The speed gate consists of two sections,

Master

and

Slave

, as well as the RC-panel (11). The

Slave

section is connected to the

Master

section via two DC and CAN connection cables (9, 10).

Each section has a sliding panel (1) and a fixed filling glass (2).

In order to increase the number of passage lanes, it is necessary to install double-sided sections.

Each double-sided section is also equipped with the RC-panel (11). It has two sliding panels (1):

on the

Master

side and

Slave

side. Each sliding panel is driven by its electric drive. The

Slave

section of the speed gate (the

Slave

side of the next double-sided section) is connected to the

Master

side with two connection cables (9, 10) from the speed gate delivery set (double-sided

section) (see Fig. 4).

1

One pair of DC and CAN cables are supplied with the nearby product.

2

Not included in the standard delivery set.