ST-02 Speed gate and STD-02 Double-sided section

25

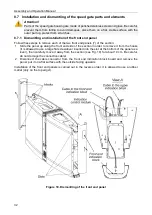

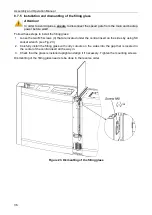

11. Check the vertical position of the section with level, the vertical deviation of the section in the

X-axis should not exceed 0.5 º. Use the special screws at the base of the section for

alignment (you will need to remove the section from the base to access them). It is allowed to

use mounting gaskets.

Note:

The following paragraphs 12 – 14 should be carried out during installation of the additional

STD-02

double-sided section.

12. Unpack and install the double-sided section. Follow the actions specified in Sections 7 – 11,

align the double-sided section so that its

Slave

side (indicated on the sticker) is placed

towards the

Master

section.

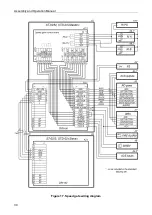

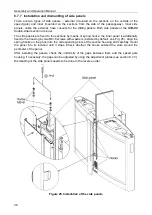

13. Route cables inside section used for controlling the second passage lane. The hole for cable

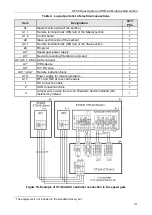

entry is located at the base of the double-sided section (from the side of the

Master

section):

from the power supply, from the RC-panel or ACS controller, from the

Fire Alarm

device and

optional equipment, as well as DC and CAN cables of the

Slave

section.

14. If necessary, install other double-sided sections (paragraphs 14 to 16).

15. Unpack and install the

Slave

section (

ST-02/S

, boxes No.3 and No.4). Follow the steps

specified in paragraphs 7 - 11.

Note:

The following paragraphs 16 to 21 shall be carried out for each individual passage lane.

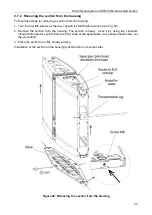

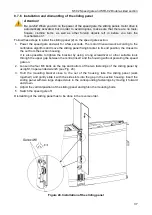

16. Remove the two screws that secure the terminal blocks to the bottom of the

Master

and

Slave

sections (sides of the sections) to the housing (see Fig. 5 ), and take them out, be

careful – do not damage the internal wiring that leads to the terminal blocks!

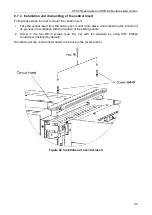

17. Take out the external connection cables from the inside of each section (the sides of the

section) and connect them to the remote terminal block in accordance with the speed gate

wiring diagram (see Fig. 17). Mount and secure the remote terminal block. Carefully lay down

the connected cables inside the housing of the section.

Note:

DC and CAN connection cables are connected to the remote terminal block of the speed

gate sections in accordance with the core marking.

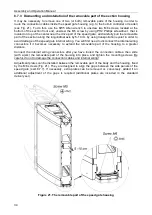

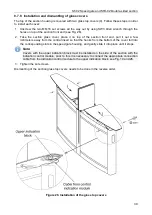

18. If necessary, install the access card reader and ACS controller – card readers are mounted

on special brackets located inside of the sections under the top indication blocks or directly

on the bottom of the indication blocks (

MR07 OEM

); the ACS controller is mounted in the

opening of the section housing, under the speed gate top cover by means of self-adhesive

clips from the delivery set (see Fig. 20).

Attention!

By default, it is possible to install the

PERCo

access card reader and ACS controller inside

of the speed gate section.

Third-party hardware must meet the following requirements:

−

overall dimensions of ACS controller,

(length × width × height) ....................................................... max. 160×140×40

mm

−

reader overall dimensions,

(length × width × height) ......................................................... max. 230×72×32

mm

−

passage sensors reading range ................................................................. min 40

mm

(

stable reading of the cards is not guaranteed in cases when the reading range of

the installed readers is less than 40 mm

).

In order to increase the reading range, the readers should be as close to the top surface of

the speed gate glass cover as possible. To do this, you can adjust the height of the bracket

by using two screws (located under the shelf bracket). For more precise adjustment, it is

recommended that the cover (3) with the top indication block is temporarily installed in its

place and the front end panel is removed (7).