16

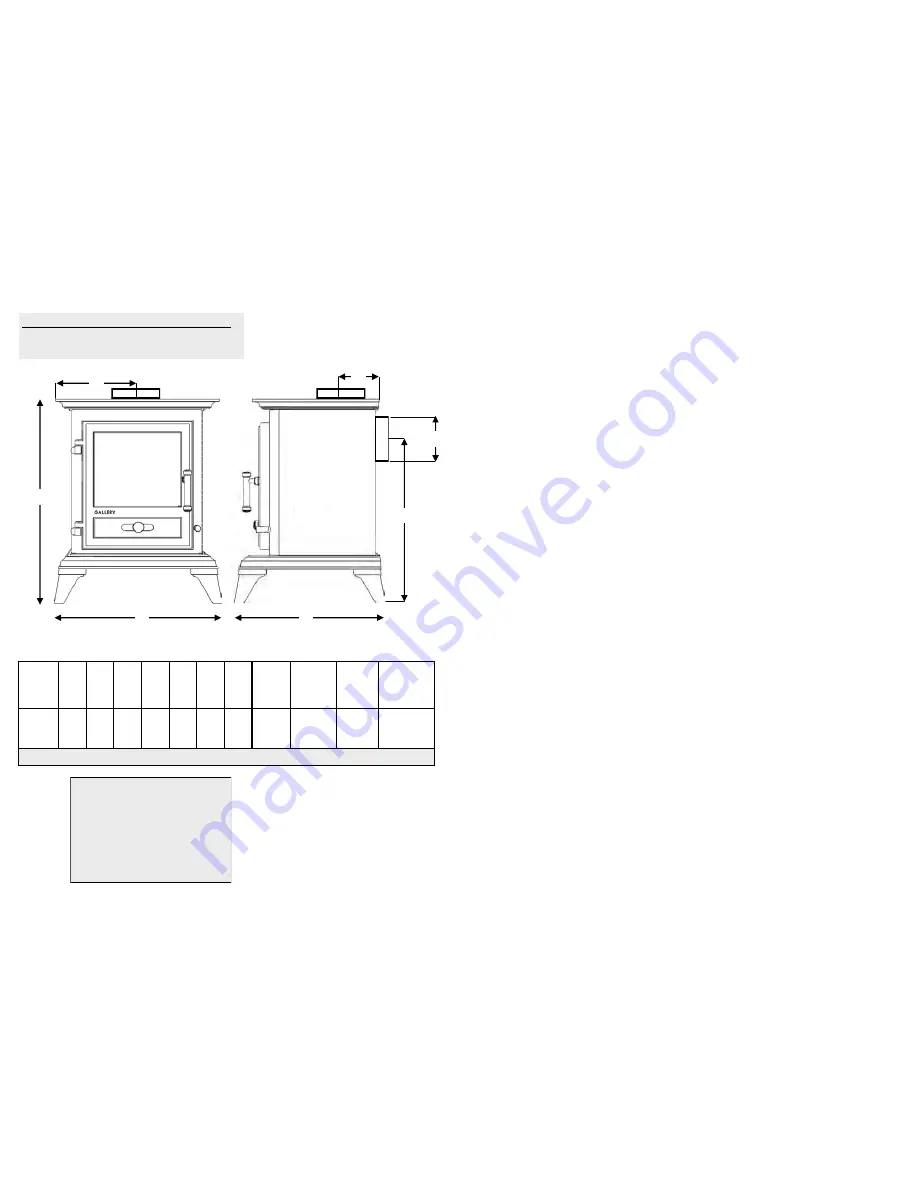

DIMENSIONS

Dims,

mm

A

B

C

D

E

F

G

Weight

Max Fuel

Load

Anthra-

cite

Minimum

Flue

Draught

Max

Fuel

Load

Wood

550

420

215

410

360

105

125

70 kg

5.33 kg

12 Pa

0.048 In

Wg

1kg

Dimensions may vary slightly, the manufacturers reserve the right to adjust them without notice.

Key To Dimensions

A—Height

B—Width

C—Centreline of Flue

D—Height To Centre of Rear Flue

E—Depth

F—Rear to Centre of Top Flue

G—Flue Diameter

See back page for flue data,

ventilation requirements and

stove outputs

Flue pipe requirement (minimum) diameter:

125mm (5 inch) nominal diameter

A

B

C

D

E

F

G

3

1

FFX008

Flue Collar

2

FFX009

Flue Blanking Plate

3,5,6

FFX001

Stove Body (Rear,Right,Left Panel)

4

FFX003

Stove Top Panel

7

FFX002

Stove Base Panel

8

FFX005

Grate Support Plate

9

FFX006

Grate

10

FFX007

Stove Baffle Plate

11

FFX012

Side Brick

12

FFX013

Back Brick

13

FFX010

Leg

14,15

FFX004

Stove Door + Front Panel

16

FFX014

Ash Pan

17

FFX011

Fret

18

FFX024

Secondary Air Duct

19

FFX018

Door Glass

20

FFX027

Glass Panel Seal

21

FFX026

Door Seal

22

FFX023

Secondary Air Slide

23,26,30

FFX022

Primary, Sec Riddling Knob Set

25

FFX020

Primary Air Slide

27

FFX029

Operating Tool

28

FFX1

Mitten

29

FFX015

Grate Riddling Rod

31

FFX016,

Door Handle Assembly

32

FFX019

Door Glass Retaining Tabs

33

FFX028

Hinge Pin

34

-

Stove Identification Label (non

-

replaceable part)

PARTS LIST