w w w . c l a s s i c

e x h i b i t s . c o m

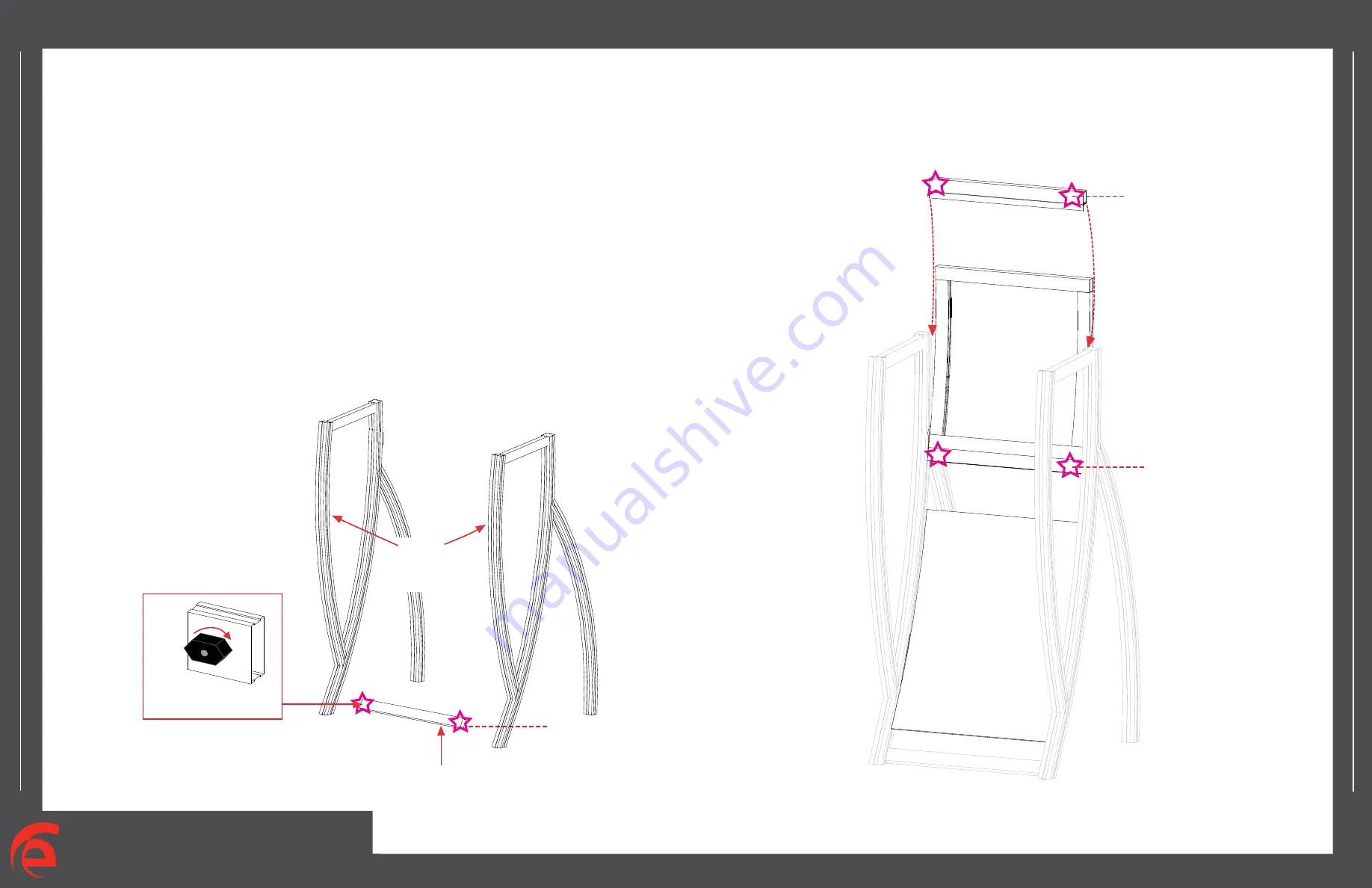

Step 1

Page 1 of 2

866.652.2100

© 2014

WHEN DISASSEMBLING ALUMINUM EXTRUSION, TIGHTEN ALL

SETSCREWS AND LOCKS TO PREVENT LOSS DURING SHIPPING

Order #XXXXX - Workstation Assembly

Part Number

A

B

C

D

Steps:

1) Connect lower horizontal extrusion [C] between bottom of leg assemblies [A and B] as shown.

2) Insert Laminated infill into grooves of leg assemblies [A and B].

3) Attach extrusion door between leg assemblies [A and B] and on top of laminated infill.

4) Attach upper horizontal extrusion w/ door stopper [D] between leg assemblies [A and B],

and set flush with top of legs [A and B].

Description

Left Leg Assembly

Right Leg Assembly

Horizontal Extrusion

Horiontal Extrusion w/ Door Stopper

Black

Knob

Turn Knob Clockwise

to Tighten Lock

DOOR

Laminated Infill

A (left)

B (right)

C

D (w/ Door Stopper)

Knobs face INSIDE

of workstation

Knobs face INSIDE

of workstation

Knobs face FORWARD

Pins are

located on INSIDE

FRONT vertical

of Leg

Assemblies

NOTE: Make sure the lock is flush with extrusion before tightening. If lock will not fully

engage, gently rock lock and extrusion back and forth while turning knob until lock

fully opens.

Align with bottom of leg assemblies [A and B].