MasterCraft 2007

Troubleshooting

(Electronic Throttle Engines)

System Not Controlling/Surging in both RPM & Speed Mode

You can quickly perform a

“Control Test”

to confirm whether PerfectPass has proper control of

the ECM. This test is on Page 3 and can be done on a “fake lake” or in the water.

The

PerfectPass “Drive by Wire” (DBW)

system for new electronic throttle engines

results in a simplified and enhanced version of PerfectPass. From the drivers seat,

PerfectPass operation is virtually identical to the present mechanical systems.

PerfectPass is now comprised of just four main parts:

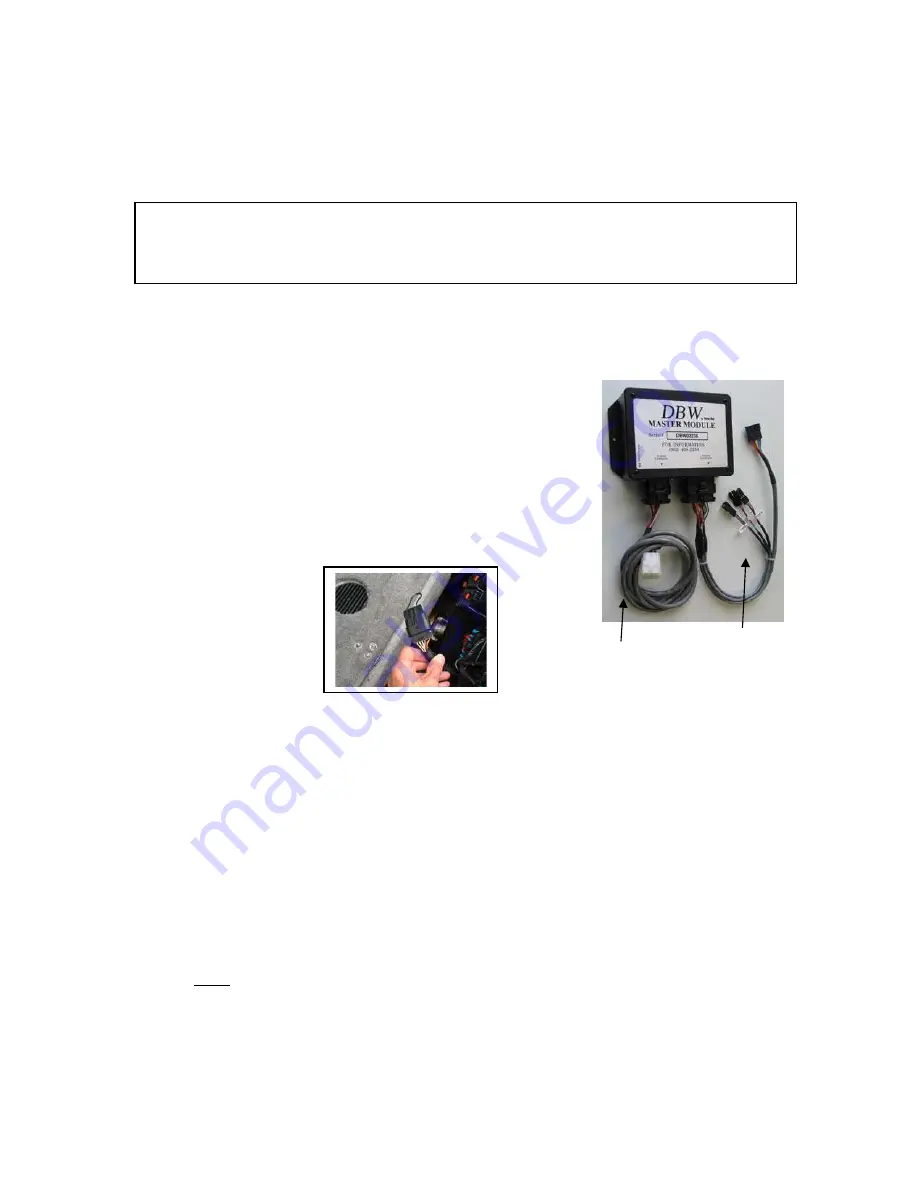

1. DBW Master Control Module

2. DBW Plug & Play Engine Wiring Harness

3. Plug & Play Display Harness

4. In-Dash

Display

5. ALDL

Plug

On 2007 MCX and RPT, an “ALDL” ground plug is

required. On the 2006 6.0L and 8.lL, a re-flash of the

ECM is required.

Engine Display

Harness Harness

How it Operates:

The ECM of an electronic throttle engine allows an external device such as PerfectPass

to control the engine rpm using the throttle servo motor when all control signals are valid

and manual throttle lever position exceeds the rpm level request of PerfectPass.

Just three individual wires in the PerfectPass DBW wiring harness connect the speed

control to the engine ECM.

1. The

Request Line

from PerfectPass requests the ECM to allow PerfectPass to take

control.

2. The

Status Line

from the ECM indicates PerfectPass now has control of the engine.

The Status Line is the signal that confirms engagement (beeper) and system control

and must be operational for system to engage & control properly.

3. The

VGOV Line

establishes the engine RPM level as set by PerfectPass.

Problems with PerfectPass should be rare given the few components that now make up

the system. Most troubleshooting will simply involve voltage/continuity testing on the

PerfectPass engine harness.

PerfectPass Control Systems (902) 468-2150

Page 1