3

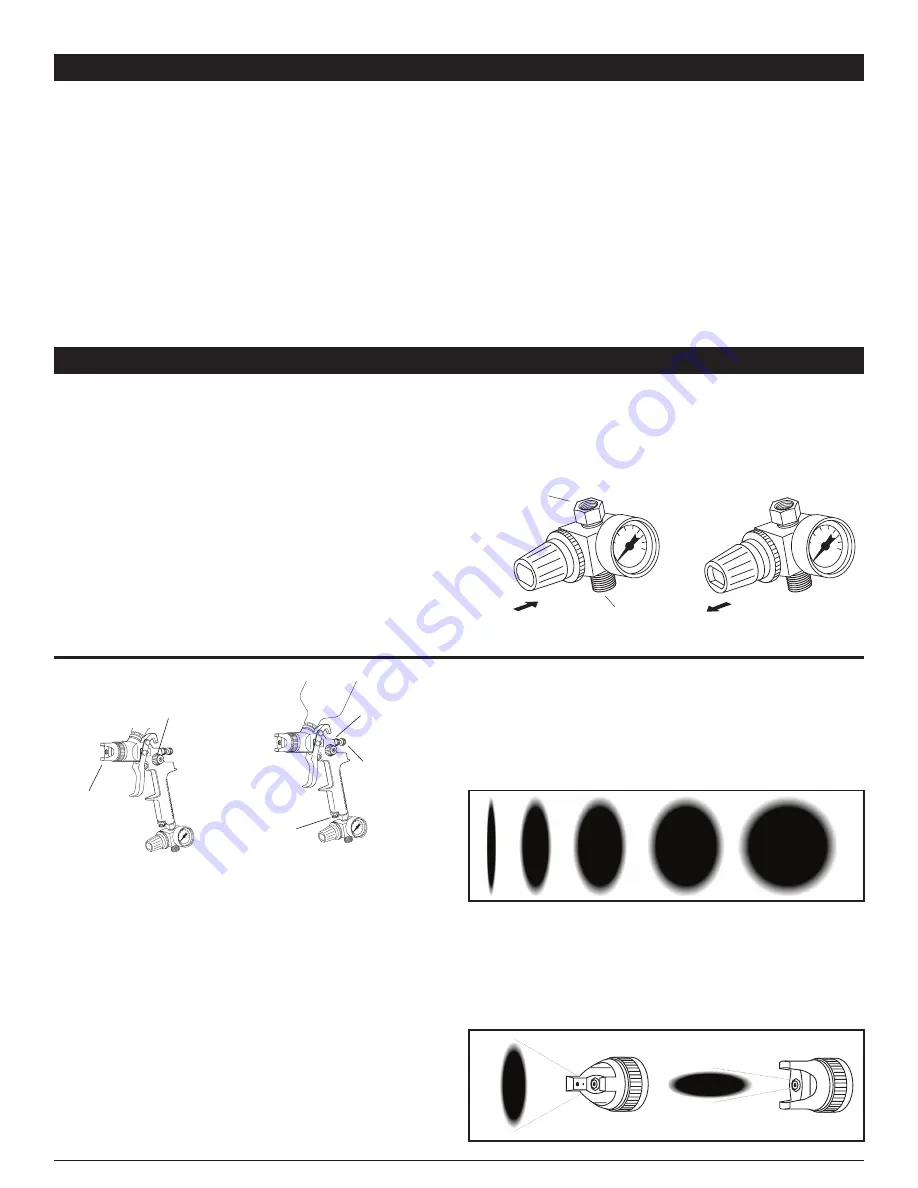

Step 3: Spray Pattern Controls

Pattern Shape - The shape of the spray can be adjusted

from a round pattern to a flat pattern by turning the Pattern

Control Knob. Turning knob in rounds the pattern, turning

knob out flattens the pattern.

Pattern Orientation - A flat or semi-round spray pattern

can be adjusted to any angle from horizontal to vertical by

turning the Air Nozzle. Pattern is perpendicular to “ears”

on nozzle. That is, when the ears are horizontal, the spray

pattern will be vertical and when the ears are vertical the

spray pattern will be horizontal.

Step 2: Air and Fluid Volume Controls

These two controls are used in conjunction with each other

to accurately adjust air/fluid (Paint) ratio and will vary for

different paints. Changing one control Fluid Volume affects

the other so alternating back and forth between them to

fine tune your adjustment will yield optimum results.

Air Volume Control - Air volume is adjusted by turning the

Air Fluid Volume Control Knob. Turning knob in reduces

volume, turning knob out Control Knob increases volume.

Fluid Volume Control - Fluid volume is adjusted by turn-

ing the Fluid Volume Control Knob. Turning knob in de-

creases volume, turning knob out increases volume. Once

a satisfactory volume is set, you can lock the adjustment

by turning the lock nut in tight.

OPERATION

Step 1: Inlet Air Pressure Regulation

Assemble components of spray gun and connect to clean

air source as described above. Clean air source is impera-

tive to ensure peak performance. The use of an in-line air

filter is highly recommended to keep any contaminants

from entering the spray gun. Set inlet air pressure to

between 40 and 45 P.S.I. to begin adjustments.

(This is a good operating inlet pressure suitable for most applica-

tions, however, depending on materials being sprayed and other

external factors such as temperature, humidity, etc., you may

need to come back to this step and increase or decrease pres-

sure as needed after attempting adjustments in step 2.)

Inlet pressure is adjusted by turning the Pressure Regula-

tor Control Knob. Knob must first be pulled out to unlock.

Turning knob clockwise increases pressure, turning knob

counter-clockwise decreases pressure. Once desired

pressure is reached, push the knob back in to lock the

adjustment.

CARE & MAINTENANCE

Warning! Clean gun before and after each use.

To protect the precision machined internal parts and fit-

tings in this gun from corrosion during shipping, some oils

or other corrosion resistant agents may have been applied.

It is important to remove any such residue before attempt-

ing to use the gun. To clean, place a small amount of

appropriate thinner into paint cup and spray through gun

while pulling and releasing trigger repeatedly. Wipe exterior

of gun, nozzles and paint cup. In some cases, if the gun

becomes clogged, disassemble completely and soak all

parts in thinner. After soaking, use wire and cleaning brush

to clear small internal passages. Check and clean paint

cup filter. Replace if worn.

A clean air source is imperative to ensure peak perfor-

mance. The use of an in-line air filter is highly recommend-

ed to keep any contaminants from entering the spray gun.

Inspect all fittings and hardware to ensure proper seating.

Be sure air line fittings are tight with no leaks. Replace any

worn parts as necessary.

Check needle and nozzles for nicks, scratches or burrs.

Any such conditions will seriously impair performance.

Replace as necessary.

Regulated air out

to Spray Gun

Unregulated

air Inlet

Pressure Regulator

Control Knob Locked

Pressure Regulator

Control Knob Unlocked

Air

Nozzle

Spray Pattern

Control Knob

Fluid Volume

Control Knob

Fluid Volume

Lock Nut

Air Volume

Control Knob