4

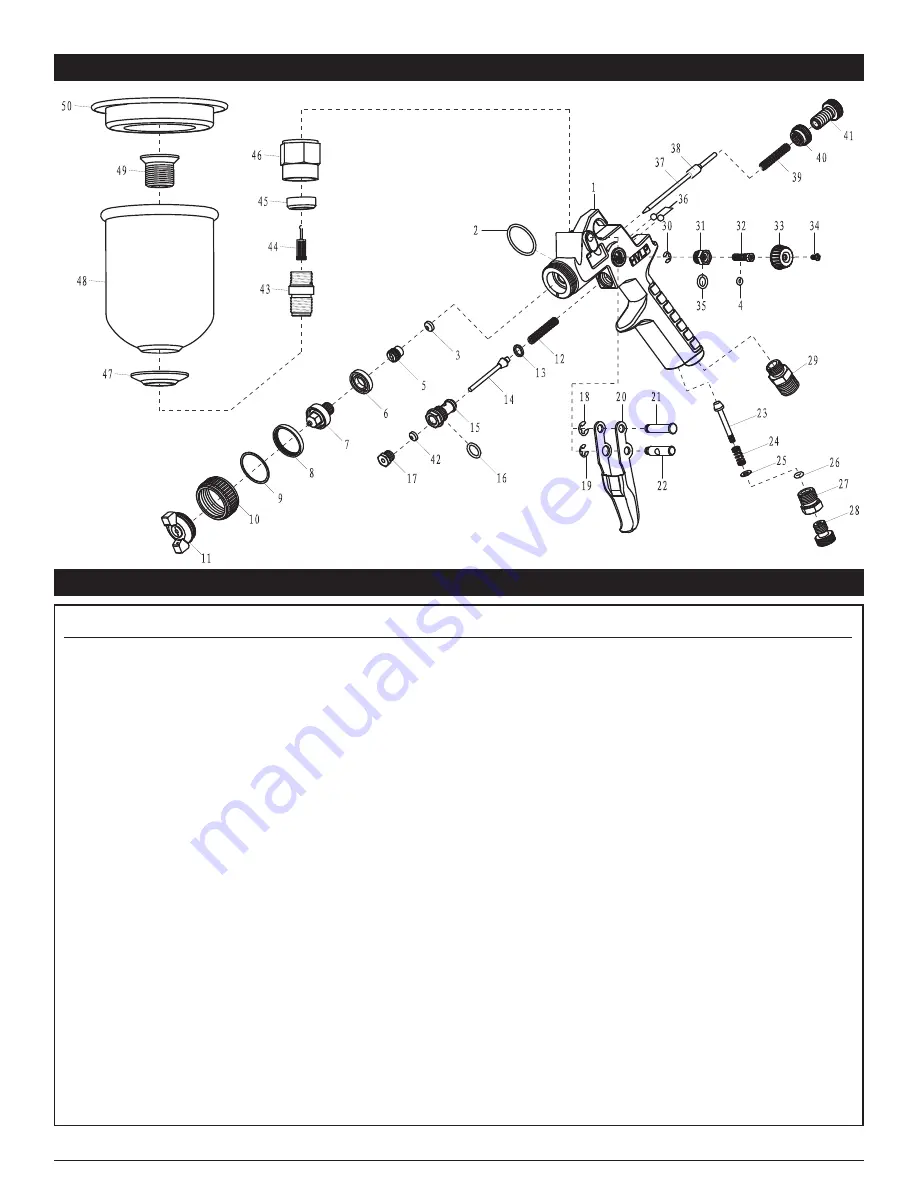

REPLACEMENT PARTS LIST

Call Customer service for replacement parts: 1-800-497-0552

REPLACEMENT PARTS LIST

#

Description

Qty.

#

Description

Qty.

1.

Gun body

1

2.

O-ring 20 x 1.5

1

3.

Sealing Gasket

1

4.

O-ring 2 x 1.5

1

5.

Fluid packing nut

1

6.

Air Isolation Ring

1

7.

Material Nozzle

1

8.

Locking Ring

1

9.

Air Nozzle Washer

1

10. Locking Knob

1

11. Air Cap

1

12. Air Valve Spring

1

13. Air Valve Sealing Gasket

1

14. Needle Valve

1

15. Air Valve Body

1

16. O-ring 8 x 1.5

1

17. Air Valve Sealing Screw

1

18. E-Clip

1

19. E-Clip

1

20. Trigger

1

21. Trigger Pin

1

22. Trigger Pin

1

23. Air Inlet Bushing

1

24. Air Valve Spring

1

25. Gasket

1

26. O-ring 2.5 x 1.8

1

27. Air Valve Control Stem

1

28. Air Flow Control Knob

1

29. Air Inlet Bushing

1

30. E-Clip

1

31. Spray Control Nut

1

32. Spray Regulator Screw

1

33. Pattern Control Knob

1

34. Screw

1

35. O-ring 6 x 1.5

1

36. Bearing

2

37. Needle

1

38. Needle Seat

1

39. Needle Spring

1

40. Needle Adjusting Seat

1

41. Needle Adjsuting Screw

1

42. Sealing Gasket

1

43. Paint Cup Coupler

1

44. Cup Filter

1

45. Sealing Gasket

1

46. Connecting Nut

1

47. Gasket

1

48. Paint Cup

1

49. Connecting Screw

1

50. Paint Cup Lid

1