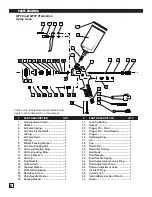

PARTS DRAWING

3

1

4

6

7

8

9

11

10

12

13 14 15

18

23

24

25

26

27

28

29

30

36

37

38

39

40

2

5

31

M706 and M707 Production

Spray Guns

32

33

34

35

16

17

19 20

21

22

6

Please note: Replacement parts listed below

apply to all models listed on this manual.

1

Air Adjustment Valve ......................... 1

21

Locking Spring ................................. 1

2

Gasket ............................................... 1

22

Gasket ............................................... 1

3

Air Valve Spring ................................. 1

23

Trigger Pin - Pivot ............................. 1

4

Air Valve Piston Shaft ....................... 1

24

Trigger Pin - Fluid Needle ................ 1

5

O-Ring ............................................... 1

25

Trigger ............................................... 1

6

Air Valve Seat .................................... 1

26

Retaining Ring .................................. 2

7

O-Ring ............................................... 1

27

Lid ..................................................... 1

8

Pliable Packing Washer .................... 1

28

Cup ................................................... 1

9

Air Valve Packing Nut ....................... 1

29

Fluid Filter ......................................... 1

10 Air Cap Retention Ring ..................... 1

30

Fluid Inlet Fitting ............................... 1

11 Air Cap Locking Ring ........................ 1

31

Gun Body .......................................... 1

12 Air Cap Washer ................................. 1

32

Fluid Needle...................................... 1

13 Air Cap ............................................... 1

33

Fluid Needle Spring .......................... 1

14 Fluid Nozzle ....................................... 1

34

Fluid Adjustment Locking Ring ....... 1

15 Air Manifold ....................................... 1

35

Fluid Adjustment Knob .................... 1

16 Tapered Washer ................................ 1

36

Pattern Adjustment Valve ................ 1

17 Air Manifold Spacer .......................... 1

37

Air Inlet Fitting .................................. 1

18 Retention Screw................................ 1

38

Gun Wrench ...................................... 1

19 Paint Needle Washer ........................ 1

39

Internal/External Hex Wrench .......... 1

20 Sealing Washer ................................. 1

40

Brush................................................. 1

#

PART DESCRIPTION

QTY .

#

PART DESCRIPTION

QTY .

Spray Gun Rebuild Kit

Numbers in black indicate parts

included in Spray Gun Rebuild Kit.