4

9

Ram Attachments:

1. The Extensions (5-8) connect in different

combinations to reach desired lengths.

2. The Male Connector (14) is used to con-

nect the female end of the Ram (3) to a

Base.

3. The Flat Base (9) is typically used on the

stationary side to spread out the force of

the Ram (3).

4. The V-Base (13) is used to offset the

force of the Ram (3) when there is not a

straight line between the stationary side

and the damaged side, or to spread out

force on curved surfaces.

SETUP INSTRUCTIONS

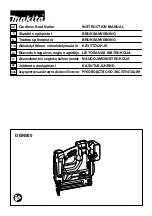

PACKAGING CONTENTS

1

Pump

1

2

Spreader Wedge

1

3

Ram

1

4

Case

1

5

3 3/4 in. Extension

1

6

5 in. Extension

1

7

8 1/2 in. Extension

1

8

16 1/2 in. Extension

1

9

Flat Base

1

10

Ram Toe

1

11

Plunger toe

1

12

Wedge head

1

13

V-base

1

14

Male Connector

1

15

Cap Head

1

16

Rubber head

1

#

Description

Quantity

#

Description

Quantity

4

5

6

7

10

12

13

8

9

14

15

16

11

5. The Cap Head (15) is typically used on

the pushing end to prevent slipping.

6. The Rubber Head (16) is typically used

for popping dents out of sheet metal such

as doors or body panels and to minimize

damage to the work surface.

7. The Wedge Head (12) is used to repair

small dents and areas located in angles

and tight spaces.

8. The Ram Toe (10) and Plunger Toe (11)

are used together to allow spreading in

areas that the Ram cannot fit into.

NOTE:

Problems listed above with more than one solution may have a combination of causes. Please be sure

that all solutions listed for each problem have been checked to eliminate possibility of further trouble.

Sometimes solutions may need to be repeated for best results.

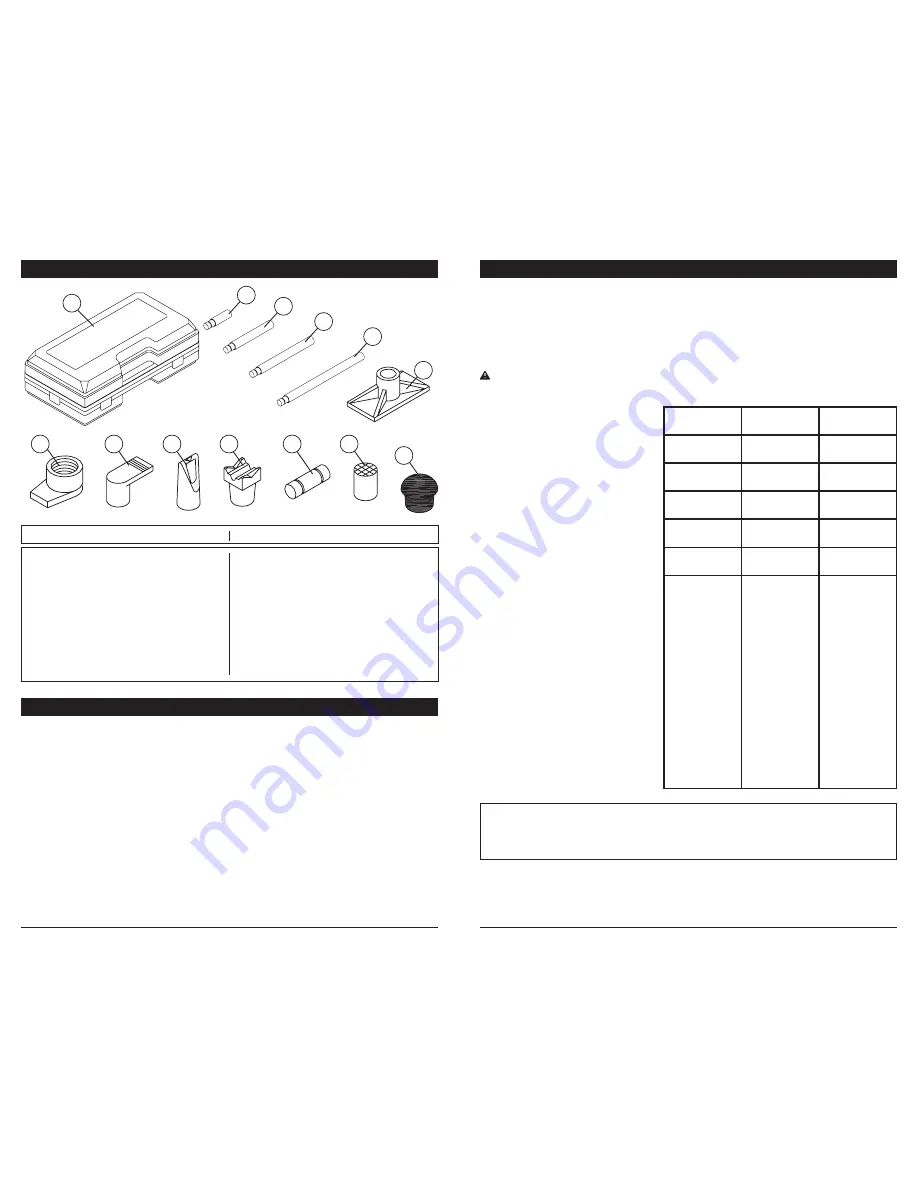

TROUBLESHOOTING

This Performance Tool® product was constructed with quality materials and workmanship

and will give you many years of trouble free use when cared for as described in the "Care

& Maintenance" section on page 7-8. However, as with any mechanical device, periodic

adjustments are necessary to maintain a peak level of performance. Should this product

be displaying any of the following symptoms, the simple procedures shown below will

correct the problem.

WARNING: Remove all equipment from service before making adjustments

●

●

●

●

●

●

●

●

●

●

Power unit may

be low in fluid.

With pump on

level surface and

in down position,

remove filler plug

and add clean

hydraulic jack fluid

to level of filler.

Power unit may

be air bound.

Open the release

valve a minimum

of 2 full turns.

Pump the handle

a minimum of 20

full strokes to

purge air from the

system.

Valve may not be

closing

completely.

To seat valves:

a.) Close release

valve.

b.) With pump in

fully lowered

position,

manually raise

lifting arm as

high as

possible.

c.) Open release

valve and

allow pump to

descend to

lowered

position

Will not lift load

Will not hold load

Will not lift to full height

Pump feels "spongy" under load

Handle raises under load

Handle lowers under load