1

1

1

2

3

4

5

4

7

7

4

4

8

8

9

9

10

10

11

12

13

14

6

15

16

17

18

19

20

21

21

22

23

24

25

26

27

27

28

29

30

30

31

31

32

32

33

33

34

34

35

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

8

9

10

10

9

8

1

1

1

6

11

14

15

16

17

18

19

20

21

21

22

17

16

15

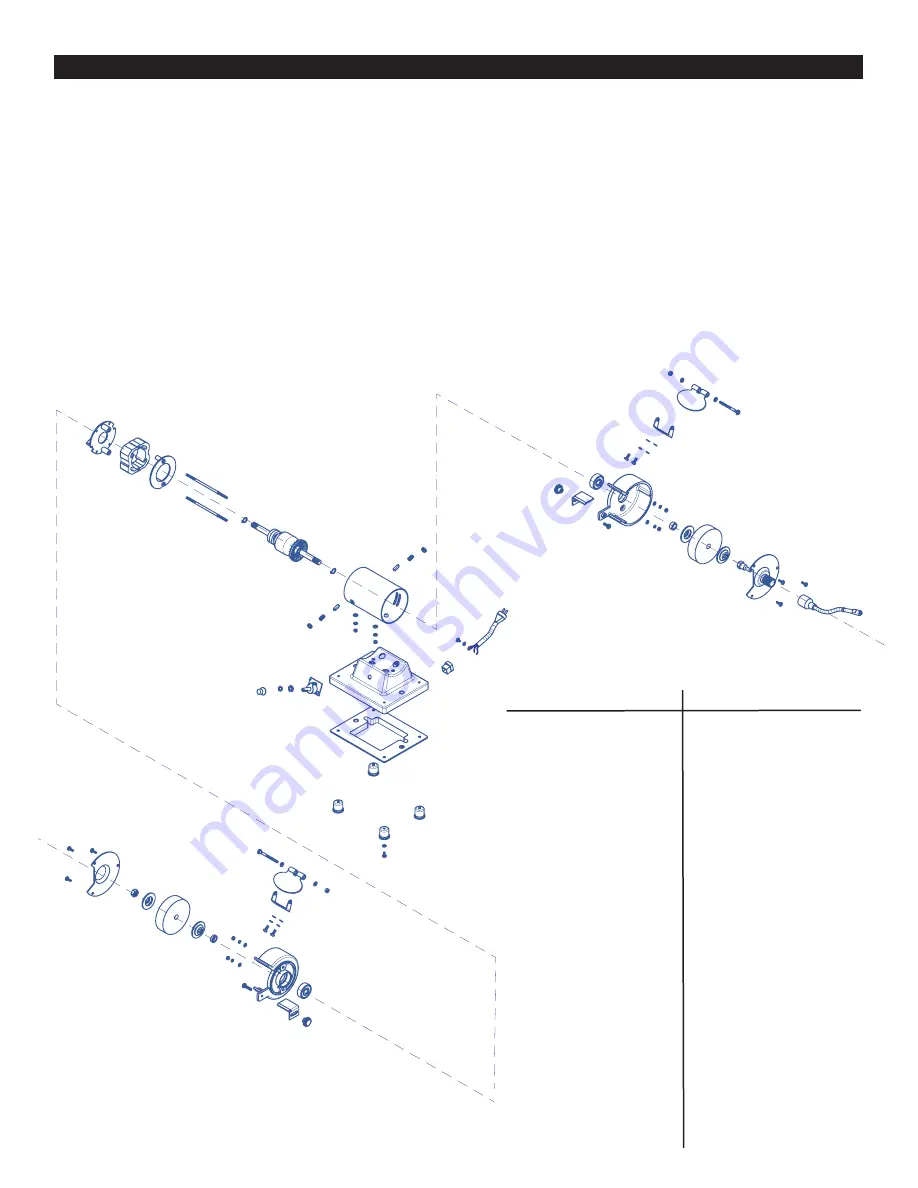

Item

Description

1

Screw

2

Left Cocer

3

Nut

4

Wheel Flang

5

Fiber Wheel

6

Bearing

7

Spindle Coller

8

Flat Washer

9

Spring Washer

10

Nut

11

Screw

12

Left Wheel Cover

13

Left Tool Rest

14

Screw Nut

15

Screw

16

Spring Washer

17

Flat Washer

18

Eyeshield Bracket

19

Eyeshield

20

Screw

21

Flat Washer

22

Nut

23

Mounting Deck

24

Stater

25

Wind Screen

26

Screw

27

Jump Ring

Item

Description

28

Roter

29

Motor Housing

30

Carbon Brush

31

Spring

32

Screw

33

Flat Washer

34

Spring Washer

35

Nut

36

Right Tool Rest

37

Right Wheel Cover

38

Grinding Wheel

39

Nut

40

Right Wheel Guard

41

Flexible Shaft

42

Base

43

Power Switch

44

Flat Washer

45

Nut

46

Switching Knob

47

Screw

48

Flat Washer

49

Cord & Plug

50

Cord Bushing

51

Base Plate

52

Rubber Foot

53

Flat Washer

54

Screw

MAINTENANCE

Dressing the Grinding Wheel

Note: New wheels frequently are not true and during operation will often become grooved, glazed (build up), out of round, or

misshapen. You will need a grinding wheel dresser for this operation (not included).

1. Stand to the side of the wheel for this operation.

2. If the wheel is new let it run for a minute with no load. If the wheel runs straight and true, you will not need to dress it prior to

operation. If it does not, proceed with the following instructions.

3. If you are using a "pistol grip" dresser,grip the handle firmly with one hand and the arm of the dresser with the other. Allow the wheel

to reach full speed. Use the tool rest to support your hand and the dresser, and evenly apply the dresser to all surfaces of the wheel.

The wheel can be dressed in a few minutes.

4. If you are using an "inline"dresser, hold the handle firmly, put the dresser on the tool rest so that its wheels can move freely (i.e.,the

exposed part of the wheel should be facing up ). Let the wheel reach full speed and apply the dresser evenly to all surfaces.