3

IMPORTANT SAFETY INFORMATION

common sense when operating this product. Do

not use this product while tired or under the influ-

ence of drugs, alcohol, or medication. A moment

of inattention while operating this product may

result in serious personal injury. Keep proper foot-

ing and balance at all times. Do not reach over or

across running machines, hoses, cords, etc.

6. Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry or long

hair can be caught in moving parts.

7. Inspect before every use; do not use if parts are

loose or damaged.

8. Do not alter this product in any way.

9. Use the right tool for the job. Do not attempt to

force a small tool or attachment to do the work

of a larger industrial tool. Don’t use a tool whose

performance is not adequate for your work. Do

not modify this tool and do not use this tool for a

purpose for which it was not intended.

10. Some dust created by grinding, drilling, saw-

ing, sanding, and other construction activities

contains chemicals known to the State of

California to cause cancer, birth defects or

other reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement

and other masonry products, and arsenic and

chromium from chemically-treated lumber.

Your risk from these exposures varies, depend-

ing on how often you do this type of work. To re-

duce your exposure to these chemicals: work in

a well ventilated area, and work with approved

safety equipment, such as dust masks that

are specially designed to filter out microscopic

particles.

11. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets

will reduce risk of electric shock.

12. Double insulated tools are equipped with a po-

larized plug (one blade is wider than the other.)

This plug will fit in a polarized outlet only one

way. If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact a

qualified electrician to install a polarized outlet.

Do not change the plug in any way. Double

insulation eliminates the need for the three wire

grounded power cord and grounded power sup-

ply system.

13. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

14. People with electronic devices, such as

pacemakers, should consult their physician(s)

before using this product. Operation of electrical

equipment in close proximity to a heart pace-

maker could cause interference or failure of the

pacemaker.

15. Do not expose power tools to rain or wet condi-

tions. Water entering a power tool will increase

the risk of electric shock.

16. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

17. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk

of electric shock.

18. If operating a power tool in a damp location is

unavoidable, use a ground fault circuit inter-

rupter (GFCI) protected supply. Use of a GFCI

reduces the risk of electric shock.

19. Prevent accidental starting. Ensure switch

is in the “OFF” position before connecting to

power source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your

finger on the switch or energizing power tools

that have the switch “ON” invites accidents.

20. Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

21. Always maintain a firm grip on the tool with

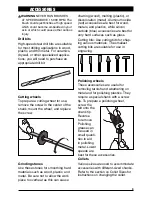

both hands. Never put your hands or feet in the

cutting area. Do not grasp the tool or place your

hands too close to the bit. Keep your hands well

away from the bit. Never reach underneath the

tool while the bit is in motion. Do not use your

legs or feet to stabilize the work piece.

22. Always hold the tool by its insulated gripping

surfaces when cutting in areas that may contain

hidden live wiring. If the bit makes contact with

a live wire, the metal parts of this tool may

conduct enough electricity to seriously shock

the user. Contact with a “live” wire will make

exposed metal parts of the tool “live” and shock

the operator. Do not cut or break into exist-

ing walls or other blind areas where electrical

wiring may exist. If this situation is unavoidable,

disconnect all fuses or circuit breakers feeding

this worksite.

23. Secure the material being worked on. Never

Summary of Contents for W50031

Page 11: ......