4

IMPORTANT SAFETY INFORMATION

hold it in your hand or across your legs. Un-

stable support can cause loss of control and

injury.

24. Be careful not to accidentally trip the power

switch when setting the tool down or picking the

tool up.

25. Make sure all nuts and screws are securely

tightened after changing bits.

26. Check to see that keys and adjusting wrenches

are removed from the Rotary Tool before switch-

ing the tool "ON". Keys or wrenches can flyaway

at high velocity striking you or a bystander.

27. Do not use the Rotary Tool if it has been dam-

aged, left outdoors in the rain, snow, wet or

damp environments, or immersed in liquid.

28. Disconnect the plug from the power source

before making any adjustments or changing

accessories. Such preventive safety measures

reduce the risk of starting the power tool

accidentally.

29. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control. Handle sharp bits with care.

30. Use the power tool, accessories and tool bits

etc. in accordance with these instructions, tak-

ing into account the working conditions and the

work to be performed. Use of the power tool for

operations different from those intended could

result in a hazardous situation.

31. Check the speed rating on all accessories. Ac-

cessories must never be run at a higher speed

than they were designed to handle.

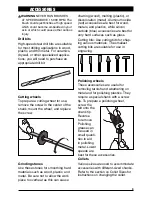

32. When using wire or bristle brushes, always

wear protective gloves and a face shield. These

brushes should never be run at speeds greater

than 15,000 RPM.

33. Always run brushes at operating speed for a

minute before using to eject loose wires and

bristles. Be sure that the discharge is pointed

away from you. Make sure no one is standing in

front or in line with the brush.

34. Do not apply heavy pressure to wire or bristle

brushes. This will only cause damage and/or

personal injury. Brushes work best when applied

lightly.

35. Do not use a wheel that may be damaged. If

the tool or wheel is dropped, install a new wheel

before continuing. Avoid bouncing and snag-

ging the wheel as this may lead to cracking or

chipping.

36. Never touch the collet or bit immediately after

use.

37. Never place hands near the spinning bit.

38. Never start the tool while bit is engaged in the

material.

38. Always feed the bit into the material in the same

direction that the chips are thrown.

39. If the bit becomes jammed in the workpiece,

turn the tool off at the switch. Once all moving

parts have come to a stop, unplug the tool and

work the bit free.

40. To prevent short circuits, clean the tool's vents

regularly with compressed air.

41. This tool is not a dental tool. Do not use on the

teeth of animals or humans.

42. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tool’s operation. If damaged, have the power

tool repaired before use. Many accidents are

caused by poorly maintained power tools.

43. Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the

power tool is maintained. Follow instructions in

the Maintenance section of this manual. Use of

unauthorized parts or failure to follow Mainte-

nance Instructions may create a risk of shock or

injury.

44. Store idle equipment. When not in use, tools

must be stored in a dry location to inhibit rust.

Always lock up tools and keep out of reach of

children and other untrained persons. Switch off

all unused electrical tools when stored. Discon-

nect battery from unit. Tools are dangerous in

the hands of untrained users.

WARNING:

This product and its packaging contain

a chemical known to the State of California to cause

cancer, birth defects, or other reproductive harm.

Summary of Contents for W50031

Page 11: ......