6

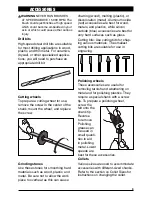

OPERATION

WARNING

Disconnect the 'power plug

from the AC power source before any

assembly,' adjustments, or adding/

removing accessories. Following this

preventative step reduces the risk of the

saw coming on accidentally and the risk

of damage to the workpiece and injury

to the operator. Never hold the tool near

your face. Accessories like wire brushes

or grinding wheels may come apart

during use.

CAUTION

Be careful not to cover the air

vents with your hand. This will cause the

motor to overheat.

This rotary tool is a multipurpose power

tool. It is a drill, polisher, power brush,

grinder, cutter, and sander all in one. This

high-speed, low torque tool is easy to

handle and accepts a wide range of acces-

sories from polishers to router bits to wire

brushes and grinding wheels. The high

speed allows it to do jobs that low speed

tools can't handle like engraving glass or

cutting hardened steel.

NOTICE

Never push on the tool. The

high speed and the accessory, not the

pressure on the tool, do the work.

TIP:

Practice by making passes on a scrap

piece of material. This tool works best

if you do the work in small increments,

moving back and forth until you reach

the desired result.

OPERATING SPEEDS

Note

Speed is affected by voltage changes. If

the incoming voltage is reduced, it will

slow the RPM of the tool, especially at

the lowest setting. If the tool appears to

be running slowly, increase the setting

accordingly.

The operating speed will vary depending on the

material and type of accessory you are using.

To find the right speed for your job, use a test

piece of the material. Try various speeds until

you find the one that is best for your project.

If you are doing delicate woodcarving, polishing,

buffing or any use which requires a wire brush,

slow speeds of 15,000 RPM or less are best.

Any material, like plastic, that melts at low

temperatures should also be cut at low speeds.

If you are carving, routing, shaping or cutting

glass, metal or hardwoods, higher speeds are

necessary. Drilling should also be done at high

speed.

Softer metals, like aluminium, copper alloys,

and tin may be cut at various speeds,

depending on the type of cutting being done. A

lubricant like wax should be used on the cutter

to keep the cut material from adhering to the

cutter teeth.

If the tool is not performing the way you think

it should, perhaps you are using the wrong

accessory. Putting pressure on the tool will not

help the performance.

CARE & MAINTENANCE

WARNING

Always UNPLUG the Rotary

Tool from the power source before in-

specting, performing any maintenance or

cleaning.

NOTICE

This Rotary Tool is lubricated

before it leaves the factory. This lubrica-

tion should last for the life of the tool. No

further lubrication is required.

Use only mild soap and a damp cloth

to clean the tool. Never let any liquid get

inside the casing. Never immerse any

part of the tool in a liquid Always keep the

ventilation openings clear.

Brushes will wear with use and should

be inspected periodically by qualified

personnel.

Regularly clean the ventilation slots in

your tool using only a soft brush or dry

cloth.

Never open the Rotary Tool case. Do not

attempt to repair the Rotary Tool yourself.

Opening the case will void your warranty.

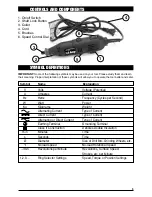

Summary of Contents for W50031

Page 11: ......