7

ACCESSORIES

Use only accessories that are recommended by

the manufacturer for your model. Accessories

that may be suitable for one tool may become

hazardous when used on another tool.

Always attach grounded (3-prong) extension

cords to grounded (3-hole) outlets.

This product should be grounded. In the

event of an electrical short circuit, grounding

reduces the risk of electric shock by providing

an escape wire for the electric current. This

product is equipped with a cord having a

grounding wire with an appropriate grounding

plug. The plug must be plugged into an

outlet that is properly installed and grounded

in accordance with all local codes and

ordinances.

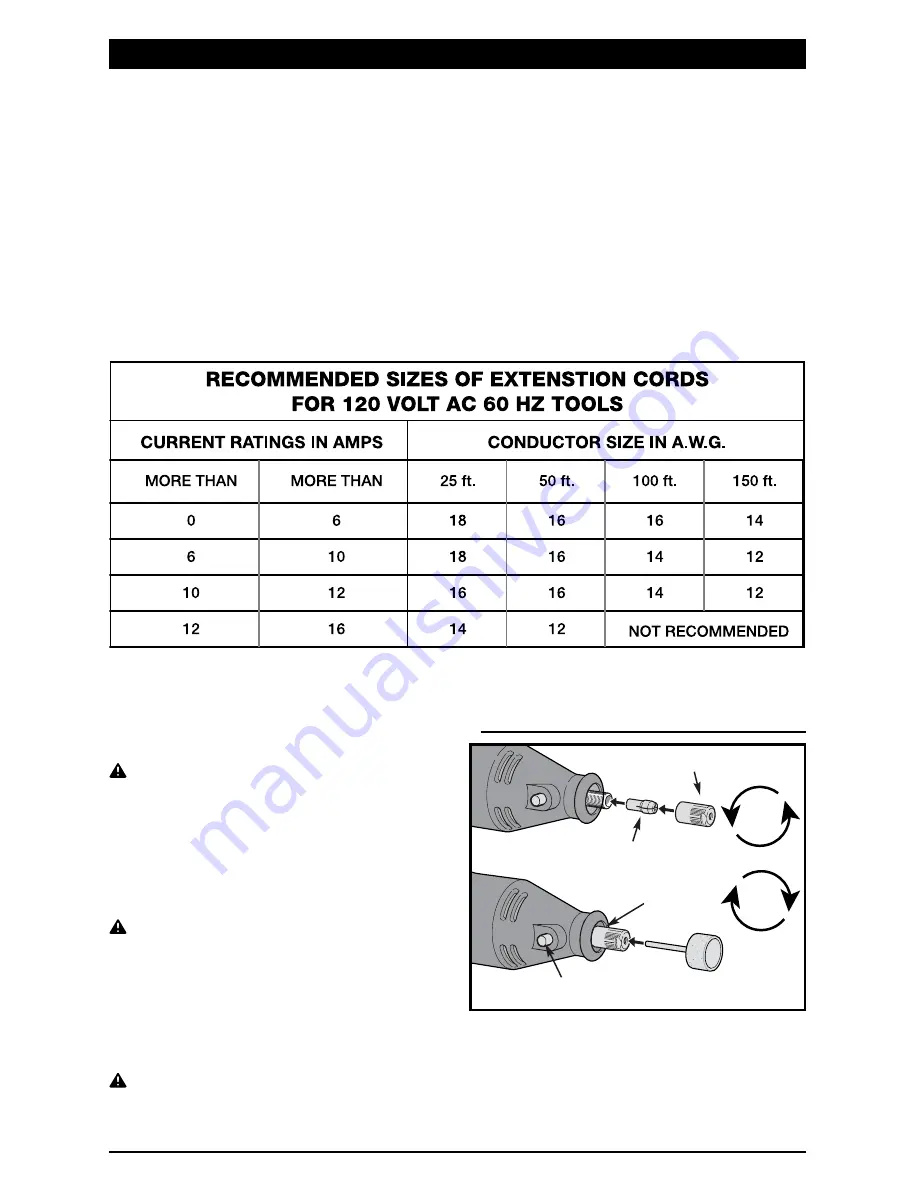

If you must use an extension cord, be sure that

the gauge is large enough to carry the amount

of current necessary for your power tool. If

not, your tool may experience a loss of power,

excessive voltage drop or overheating. The

smaller the gauge number, the heavier the cord

(see table below).

WARNING

Always unplug rotary tool

before changing accessories, changing

collets or servicing. The tool could start

unexpectedly, causing serious injury.

1. Press the shaft lock button. Rotate the

shaft manually until the lock engages and

prevents further rotation.

WARNING

Do not engage lock while the

rotary tool is running.

2. With the shaft lock button engaged,

loosen collet counter-clockwise enough

to remove the old accessory (if any) and

install the new accessory, being sure to

push it as far as possible into the collet.

NOTICE

Never force a larger diameter

shank into a collet. Always match the

collet nut to the shank size of the acces-

sory to be used.

3. With the shaft lock button still engaged,

tighten collet clockwise by hand to

secure accessory in place.

INSERTING/REMOVING ACCESSORIES

COLLET

COLLET NUT

SHAFT LOCK

BUTTON

KEYLESS

CHUCK

ASSEMBLY

Release

Grip

Summary of Contents for W50031

Page 11: ......