8

ACCESSORIES

BALANCING

1. Stop the tool.

2. Loosen the collet nut.

3. Rotate the accessory 1/4 turn.

4. Tighten the collet.

5. Run the tool.

6. Continue adjusting as needed. You will

hear and feel when the accessory is

properly balanced.

For best results, be sure to balance each accessory in the collet. Your tool’s high RPM

makes imbalances easily detectable as a wobble while the tool is running. To balance an

accessory:

CHANGING COLLET SIZES

TO CHANGE A COLLET:

1. Loosen the collet nut as described

above, then remove the collet nut.

2. Remove the old collet.

3. Insert the loose collet.

4. Tighten the collet nut as described

above.

Your rotary tool kit may have multiple collets to accommodate different accessories with

varying shank sizes.

TYPES OF ACCESSORIES

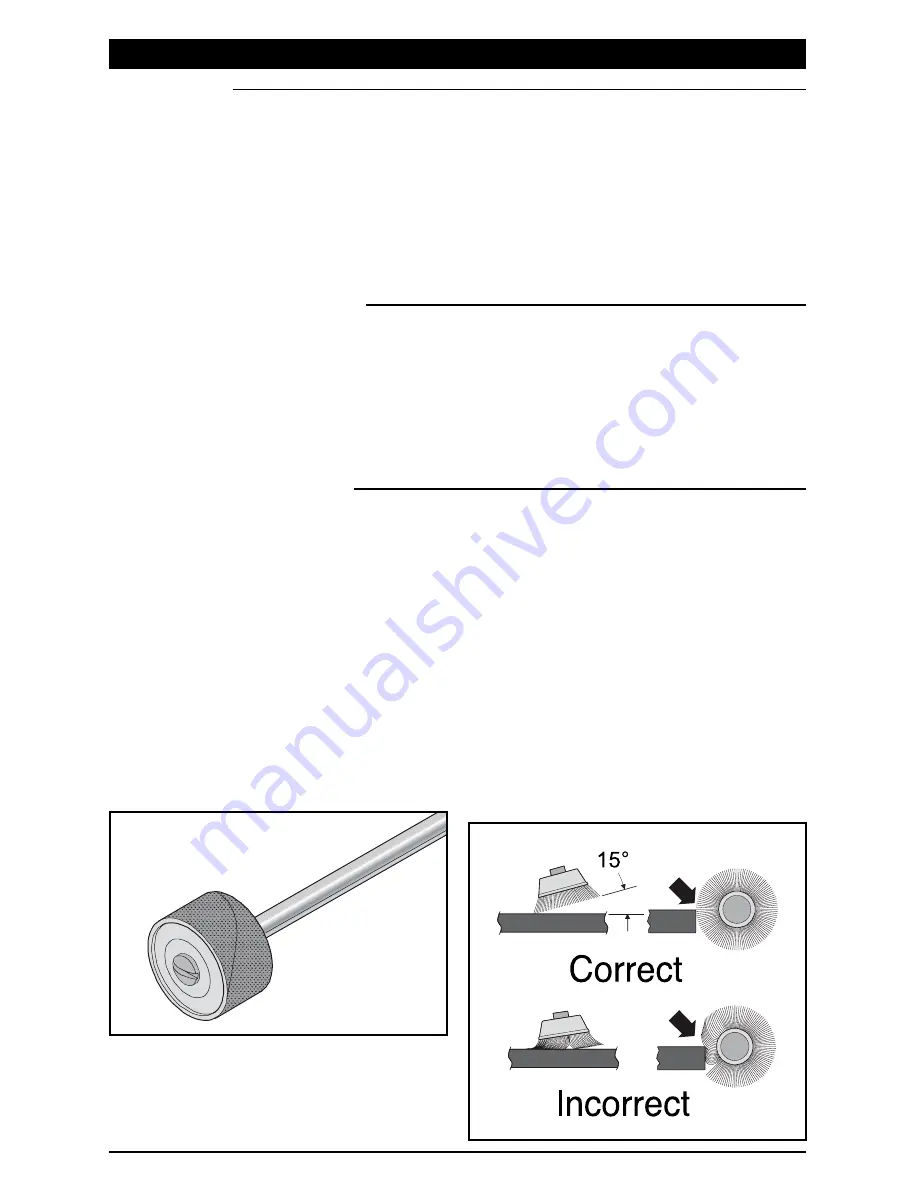

Sanding Bands

These small drum sanders help you shape

and smooth surfaces in tight places.

Replace bands when they become worn.

Bands come in fine grades for finish

and delicate work and coarse grades for

heavier work. Sanding bands work best at

lower speeds. Experiment with scrap mate-

rial before working on an actual project. To

use a sanding band, loosen the screw in

the shank, slip the band onto the shank,

then tighten the screw to secure the band.

Brushes

Wire brushes are useful for clean-

ing and polishing metal, while bristle

brushes are suitable for cleaning softer

surfaces. As with all rotary tool acces-

sories, you should let the speed do

the work without applying excessive

force. Use the bristle tips only without

mashing the brush against the work

piece as shown in the top part of the

illustration on the right.

Your rotary tool may be used with the following accessories:

Summary of Contents for W50031

Page 11: ......