10

ASSEMBLY AND ADJUSTMENTS

Remove the random orbit sander from the carton and examine it carefully. Do not

discard the carton or any packaging material until all parts are examined.

NOTE: If any part of the random orbit sander is missing or damaged, do not

plug the sander in until the damaged part is repaired or replaced.

WARNING: To avoid injury, ALWAYS turn the switch OFF and disconnect

the sander from the power outlet before installing or changing the abrasive

discs or dust bag attachment.

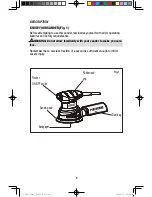

INSTALLING AND REMOVING THE ABRASIVE DISC (See Fig. 2)

To install:

1. Unplug the sander.

2. Remove all sanding dust or dirt from the

sanding pad.

3. Align the holes on the abrasive disc with the

holes in the sanding pad, making sure that

the pad is centered and the edges are aligned

with the edges of the sanding pad.

Note:

The holes in the abrasive disc must line up

with the sanding pad holes for the dust collection

system to function properly.

4. Press the abrasive disc to the pad.

To remove

1. Unplug the sander.

2. Peel the disc off the sanding pad.

INSTALLING AND REMOVING THE DUST BAG (See Fig. 3)

To install:

Press the dust bag port down into the slot in

the dust chute until the chute’s detent fully

engages with the holes.

To remove:

Lift the bag port up. To empty the dust bag,

remove the bag from the sander, and gently

tap it to remove the dust.

OPERATION

Fig. 2

Fig. 3

10-06-17 manual 241-0972 En.indd 10

2010-6-18 12:00:05