11

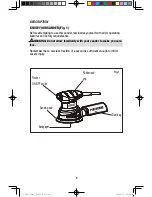

ROCKER ON/OFF SWITCH

This random orbit sander is equipped with a dust-sealed ON/OFF rocker switch,

located on the front of the handle.

1. To turn the sander ON, depress the rocker switch to the “I” position.

2. To turn the tool OFF, depress the rocker switch to the “O” position.

GENERAL SANDING

WARNING: Finish sanding can produce clouds of fine sanding dust that

could ignite in the presence of sparks or an open flame. To avoid injury,

always use your sander in a well ventilated area.

1. Place the sander on the workpiece BEFORE turning the switch ON. If the

sander is started before making contact with the workpiece, the free floating

work pad may cause scratches.

2. Move the sander in long sweeping strokes parallel to the grain, using some

lateral motion to overlap the strokes by as much as 75%. The random orbit

action allows cross-grain sanding, but be careful not to tilt the sander near

edges, or undesirable rounding may result.

3. The amount of downward pressure will affect the rotation speed and sanding

results:

a. Light pressure: recommended for fine work

b. Moderate pressure: recommended for rough work.

c. Do not exert heavy pressure; it does not allow the disc to rotate sufficiently.

4. Keep the sanding disc flat on the workpiece. Using the edges of the pad or

tipping the sander may cause an uneven finish and reduce the life of the

sanding pad.

5. Begin sanding with a coarser grit sandpaper and gradually use finer and finer

grits until the desired finish is achieved. Do not switch from a coarse grit to a

very fine grit in one step.

6. Random orbit sanders work more aggressively than simple orbital sanders.

Check your workpiece frequently.

7. To help prevent swirl marks when the job is completed, gently lift the tool from

the work surface, then switch the tool off.

10-06-17 manual 241-0972 En.indd 11

2010-6-18 12:00:05