8

WARNING:

Keep the extension cord

clear of the working area.

Position the cord so

it will not get caught on the workpiece, tools or

any other obstructions while you are working

with the power tool.

Make sure any extension cord used with this

tool is in good condition. When using an

extension cord, be sure to use one of heavy

enough gauge to carry the current the tool will

draw. An undersized cord will cause a drop in

line voltage resulting in loss of power and

overheating.

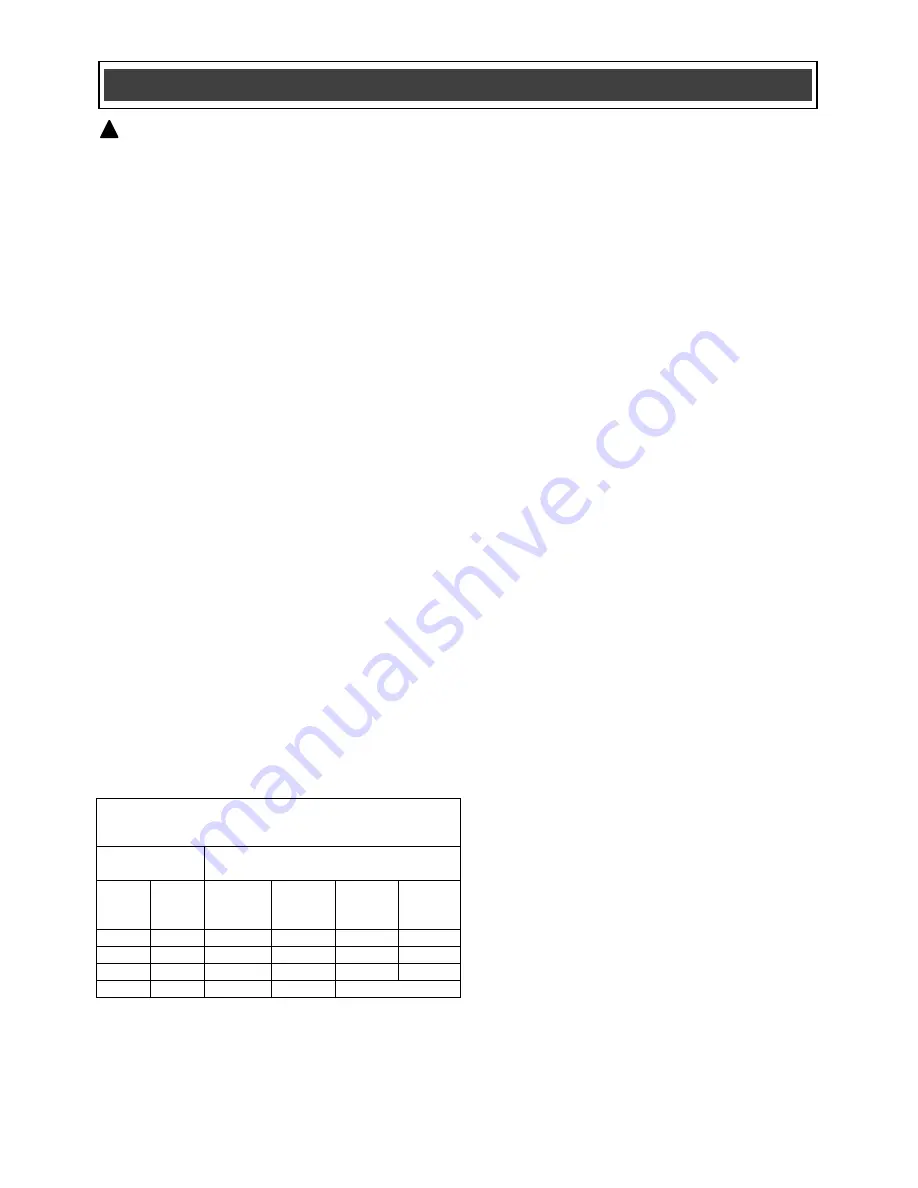

The table at right shows the correct size to use

according to cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge.

The smaller the gauge number the heavier the

cord.

Be sure your extension cord is properly wired

and in good condition. Always replace a

damaged extension cord or have it repaired by a

qualified electrician before using it. Protect your

extension cord from sharp objects, excessive

heat and damp or wet areas.

Use a separate electrical circuit for your power

tools. This circuit must not be less than 14

gauge wire and should be protected with either

a 15 A time delayed fuse or circuit breaker.

Before connecting the power tool to the power

source, make sure the switch is in the OFF

position and the power source is the same as

indicated on the nameplate. Running at lower

voltage will damage the motor.

MINIMUM GAUGE (AWG)

EXTENSION CORDS

(120 V use only)

Amperage

rating

Total length

More

than

Not

more

than

25'

(7.5 m)

50'

(15 m)

100'

(30 m)

150'

(45 m)

0

6

18

16

16

14

6

10

18

16

14

12

10

12

16

16

14

12

12

16

14

12

Not Applicable

EXTENSION CORD SAFETY

!

SAVE THESE INSTRUCTIONS FOR REFERENCE

Summary of Contents for 241-0994

Page 14: ...14 EXPLODED VIEW...