13

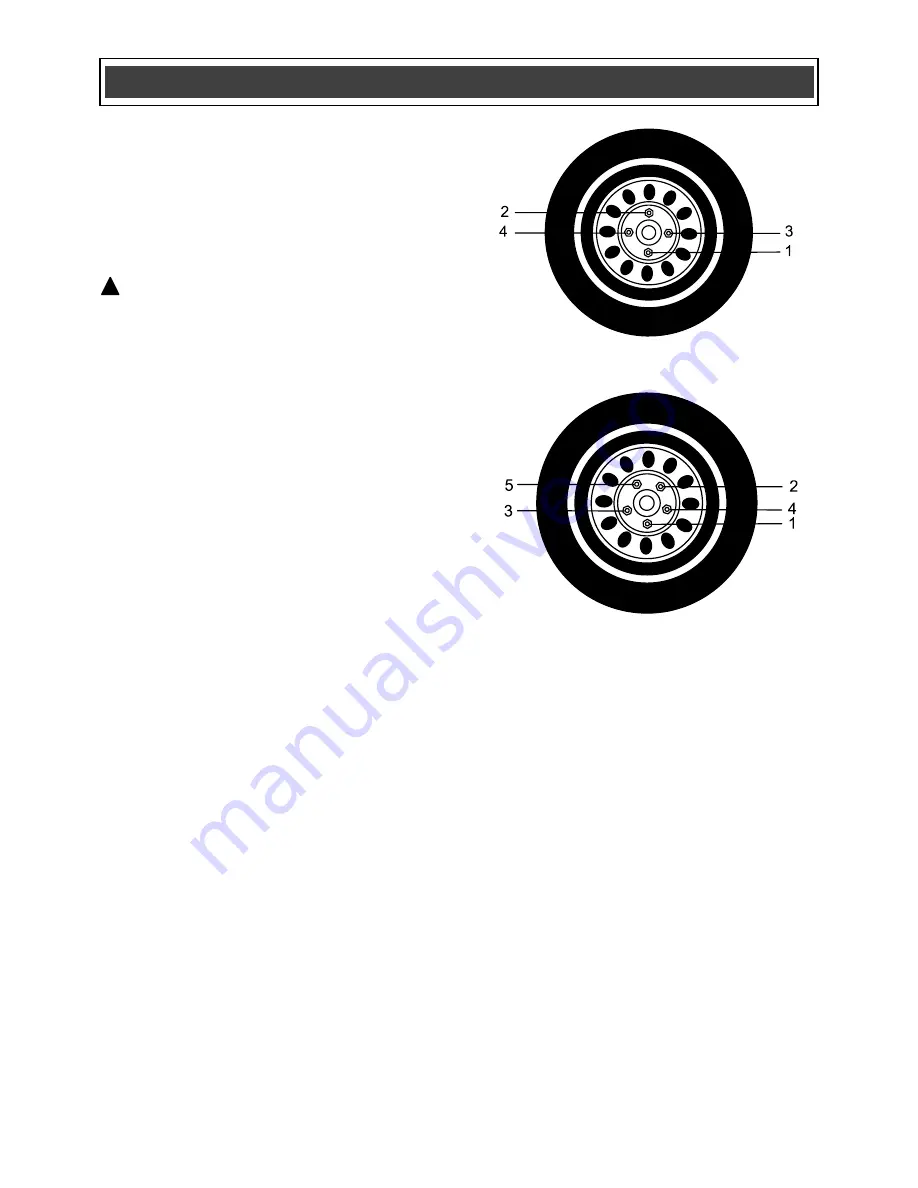

TIGHTENING WHEEL NUTS

– cont’d

NOTE:

Release the trigger switch

IMMEDIATELY when the impact mechanism

“rattles”.

6.

Proceed with tightening the remaining

wheel nuts as noted above.

WARNING:

Tighten the wheel nuts in

the sequence outlined in Fig. 4 for 4 stud

wheel patterns and Fig. 5 for 5 stud wheel

patterns.

Following this sequence is

extremely important to avoid potential

distortion of the brake rotors or drums.

7.

Use a torque wrench to tighten all wheel

nuts to the manufacturer’s recommended

torque. Follow the same tightening

sequence as noted above.

8.

Once the wheel nuts have been tightened,

lower the vehicle so the wheel is firmly in

contact with the ground and verify the

torque of each wheel nut using a

conventional torque wrench.

ASSEMBLY AND OPERATION

!

Fig. 4

Fig. 5